P-benzoquinone condensation crystallization technology

A technology for condensation crystallization and p-benzoquinone, applied in the field of p-benzoquinone condensation and crystallization process, can solve the problems of inability to continuously perform solid-liquid separation, easy crystallization and blockage of descending pipes, low stripping production efficiency, etc. Product purity, yield enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

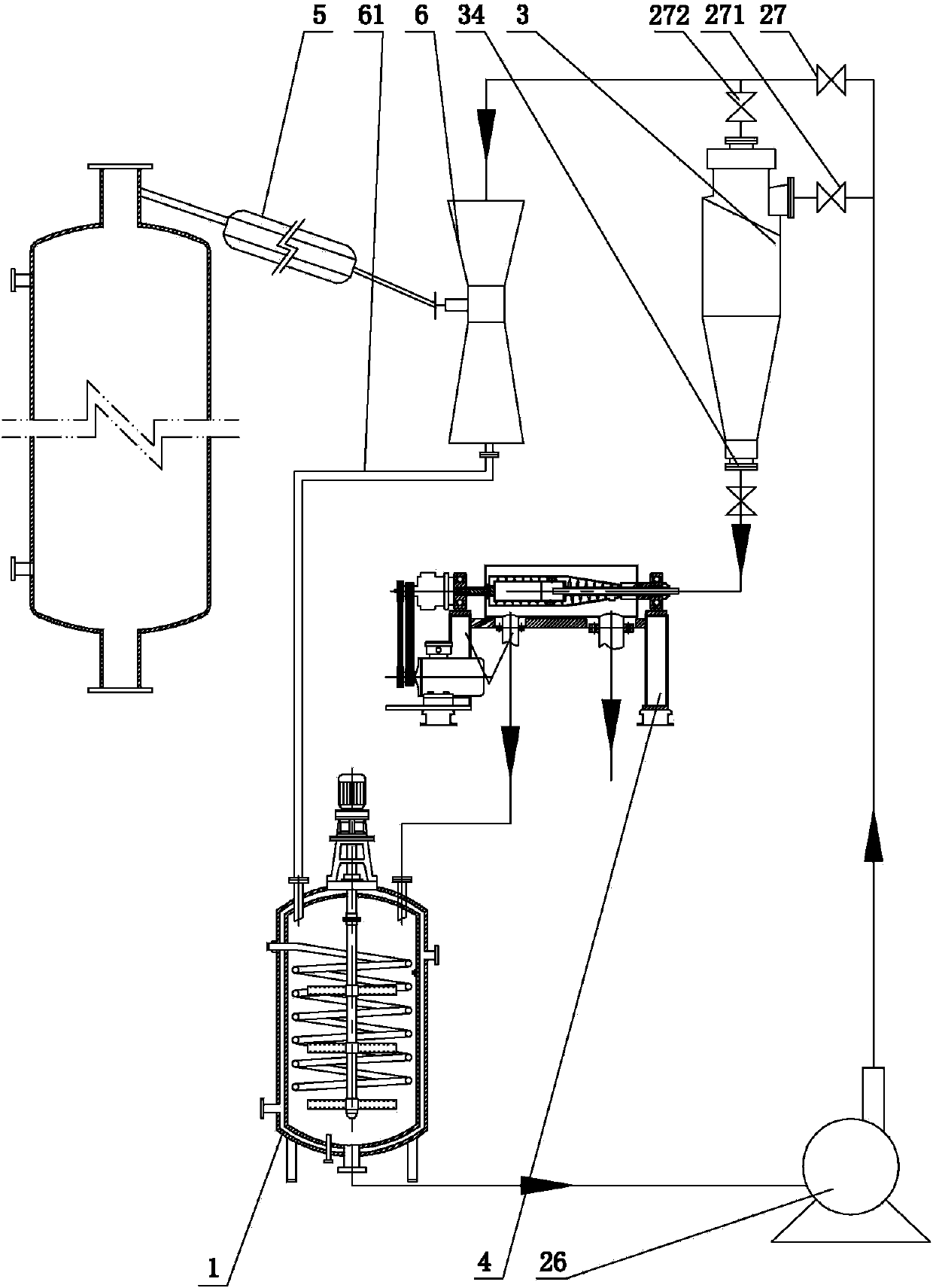

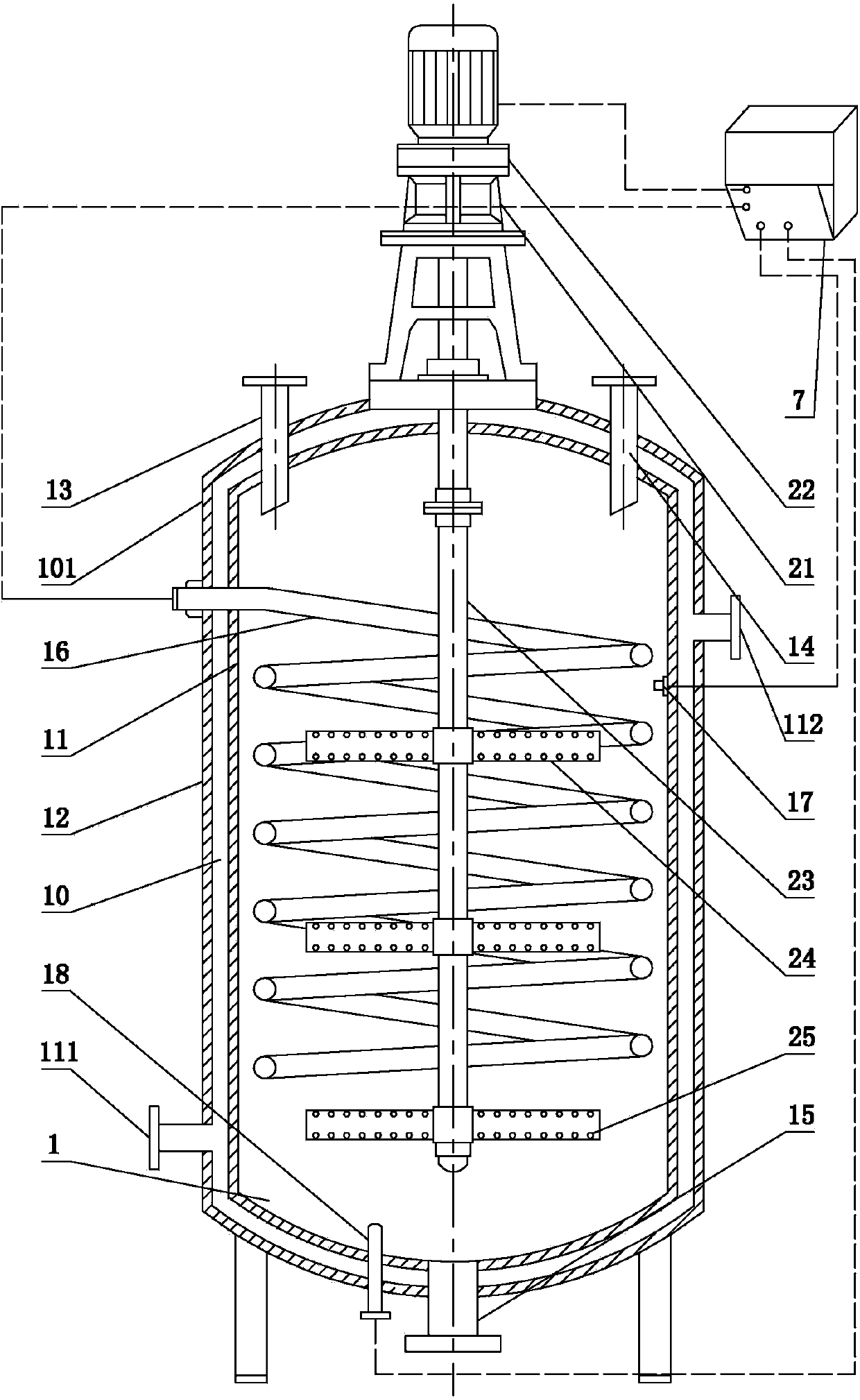

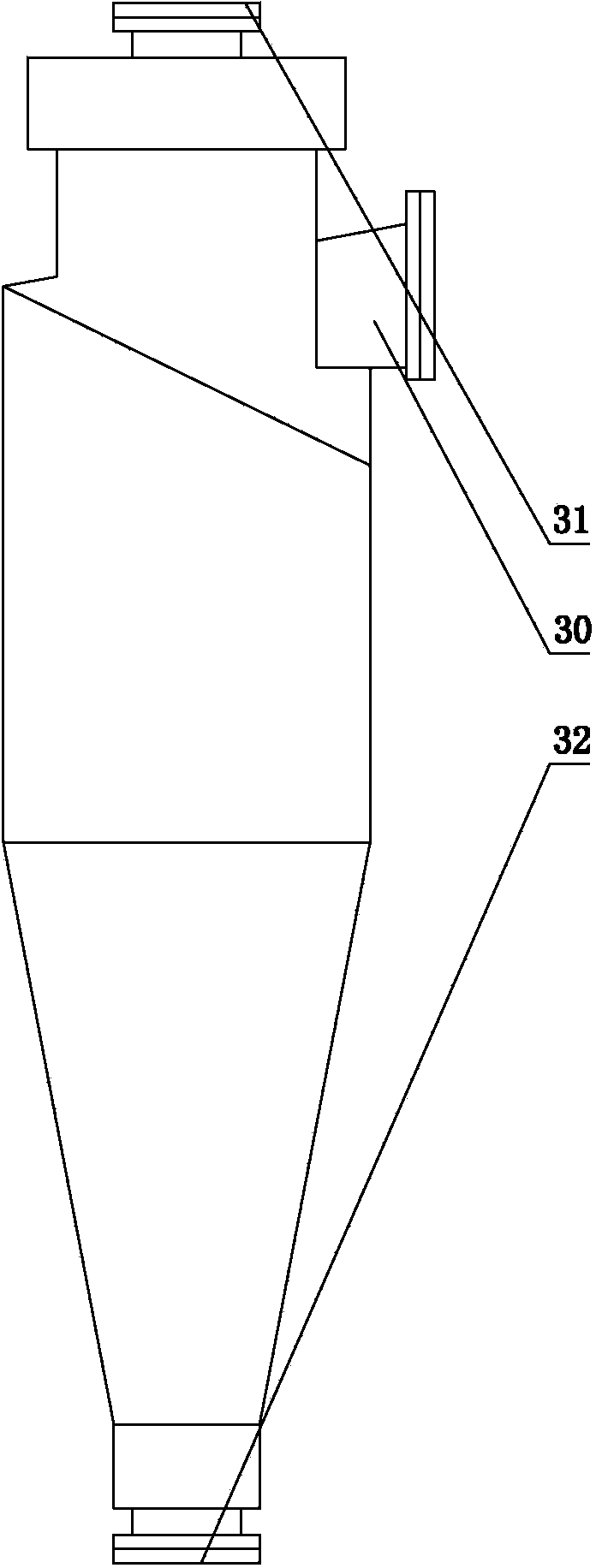

[0026] Embodiment 1: When opening the Venturi tube feed valve 27 and closing the cyclone separator control valves 271, 272, the water vapor containing gas phase quinone at the top of the stripping tower is sucked by the negative pressure of the Venturi tube 6 Next, pass hot water into the condenser 5 through the condenser 5 near the top of the stripping tower to lower the temperature of the water vapor to 80-100°C. The water vapor passing through the condenser 5 is sent into the crystallization kettle 1 through the Venturi tube 6 and the downcomer 61, and ice water is introduced into the jacket layer 10 of the crystallization kettle 1 to reduce the temperature in the crystallization kettle 1 to 0-20 ℃, the crystallization tank 1 is stirred by the paddle stirring blade 24, the cooling water is circulated and quenched, etc., so that p-benzoquinone is precipitated in the form of crystals, and the crystallization mixture generated in the crystallization tank 1 is formed. The low-con...

Embodiment approach 2

[0027] Embodiment 2: When closing the Venturi tube feed valve 27 and opening the cyclone separator control valves 271, 272, the water vapor containing gas phase quinone at the top of the stripping tower is sucked by the negative pressure of the Venturi tube 6 Next, pass hot water into the condenser 5 through the condenser 5 near the top of the stripping tower to lower the temperature of the water vapor to 80-100°C. The water vapor passing through the condenser 5 is sent into the crystallization kettle 1 through the Venturi tube 6 and the downcomer 61, and ice water is introduced into the jacket layer 10 of the crystallization kettle 1 to reduce the temperature in the crystallization kettle 1 to 0-20 ℃, the crystallization tank 1 is stirred by the paddle stirring blade 24, the cooling water is circulated and quenched, etc., so that p-benzoquinone is precipitated in the form of crystals, and the crystallization mixture generated in the crystallization tank 1 is formed. The cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com