Manufacturing method for aramid fiber/chinlon composite cord for aircraft tires

A technology for aviation tires and composite cords, applied in the field of tire cords, to achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

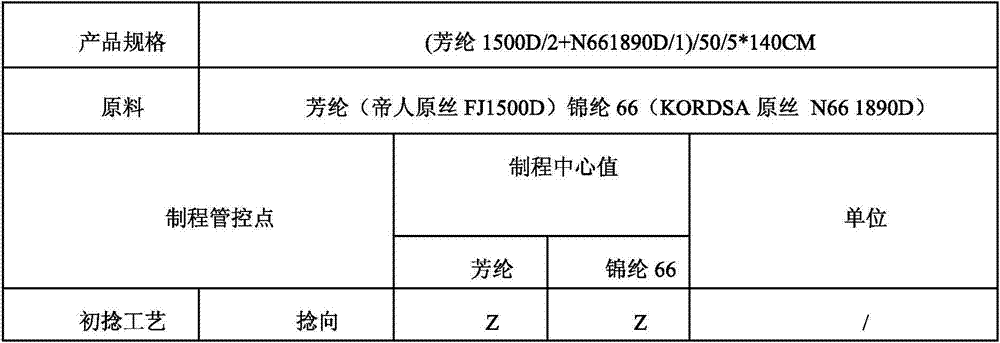

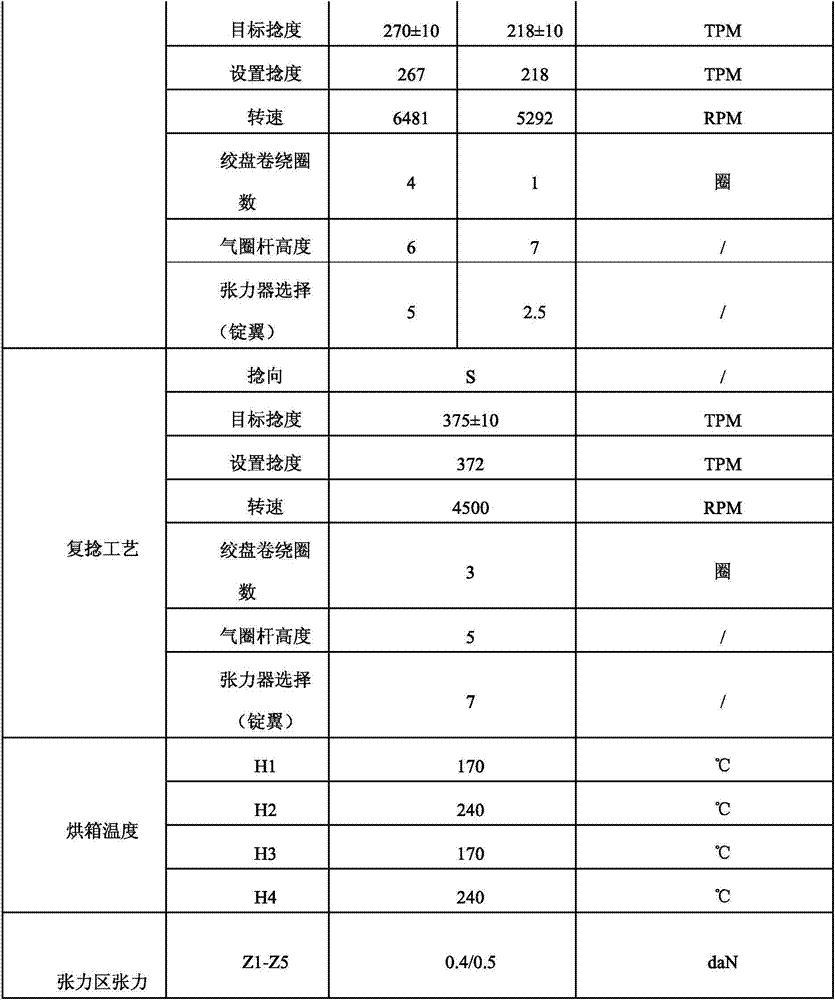

[0020] 1. The process parameters are as follows:

[0021] Table 1 Example 1 of the process parameters of a manufacturing method of aramid / nylon composite cords for aircraft tires

[0022]

[0023]

[0024] 2. The specific production process includes the following steps:

[0025] 1) Aramid raw silk and nylon raw silk blended twisted yarn: choose to use UT60 two-for-one twister to carry out blended twisting of aramid raw silk and nylon 66 raw silk. During the initial twisting, the twisting production is carried out according to the initial twisting process. There are three spindles, the raw silk of the two spindles is aramid raw silk, and the raw silk of the middle spindle is nylon 66 raw silk. According to the process parameters, the twist, the number of winding turns of the capstan, the height of the balloon, etc. are set. During the initial twisting, All the tensioners use flyers. When retwisting, select a spindle position and set parameters such as twist according to ...

Embodiment 2

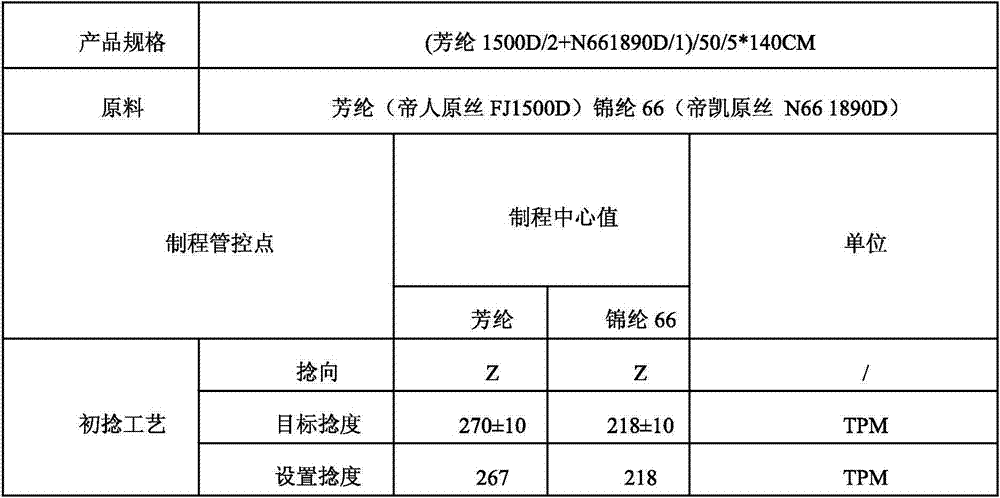

[0030] 1. The process parameters are as follows:

[0031] Table 2 Example 2 of the process parameters of a manufacturing method of aramid / nylon composite cords for aircraft tires

[0032]

[0033]

[0034] 2. The specific production process includes the following steps:

[0035] 1) Aramid raw silk and nylon raw silk blended twisted yarn: choose to use UT60 two-for-one twister to carry out blended twisting of aramid raw silk and nylon 66 raw silk. During the initial twisting, the twisting production is carried out according to the initial twisting process. There are three spindles, the raw silk of the two spindles is aramid raw silk, and the raw silk of the middle spindle is nylon 66 raw silk. According to the process parameters, the twist, the number of winding turns of the capstan, the height of the balloon, etc. are set. During the initial twisting, All the tensioners use flyers. When retwisting, select a spindle position and set parameters such as twist according to ...

Embodiment 3

[0040] 1. The process parameters are as follows:

[0041] Table 3 Example 3 of a manufacturing method of aramid / nylon composite cords for aircraft tires

[0042]

[0043]

[0044]2. The specific production process includes the following steps:

[0045] 1) Aramid raw silk and nylon raw silk blended twisted yarn: choose to use UT60 two-for-one twister to carry out blended twisting of aramid raw silk and nylon 66 raw silk. During the initial twisting, the twisting production is carried out according to the initial twisting process. There are three spindles, the raw silk of the two spindles is aramid raw silk, and the raw silk of the middle spindle is nylon 66 raw silk. According to the process parameters, the twist, the number of winding turns of the capstan, the height of the balloon, etc. are set. During the initial twisting, The tensioner of the aramid raw yarn is a flyer, and the tensioner of the nylon 66 raw silk is a spindle bar. When re-twisting, select a spindle po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com