Inner suspension film hollow glass

A glass and hollow technology, applied in the field of inner suspension film insulating glass, can solve the problems of the service life and application limitation of the insulating glass film, and achieve the effect of low K value, good heat insulation effect, and improved thermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The hollow glass with inner suspension film of the present invention is manufactured and assembled according to the design requirements in the manufacturing workshop, and installed on the doors and windows of the building or the aluminum frame of the curtain wall.

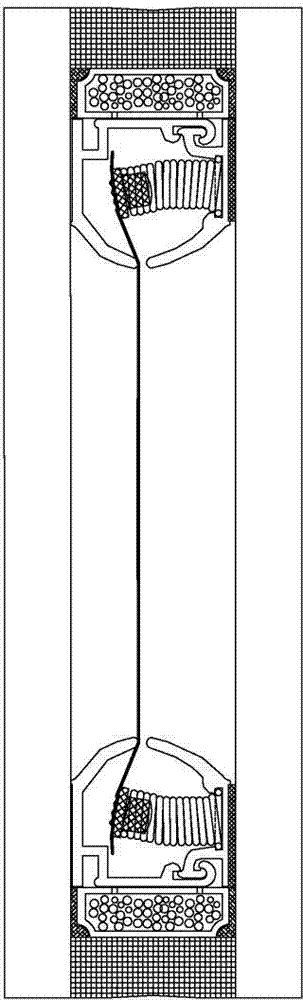

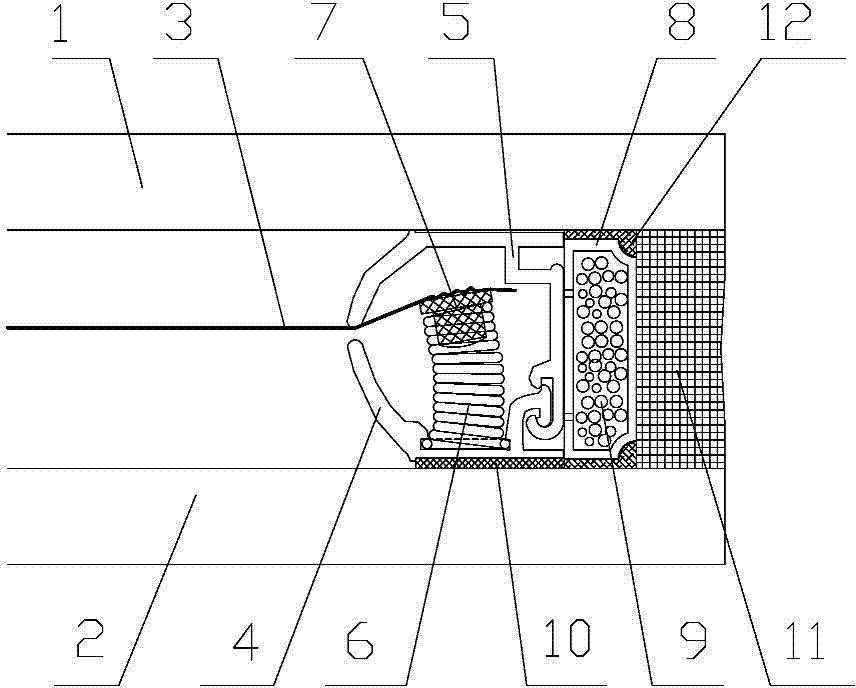

[0037] Such as figure 1 , figure 2 As shown, the outer glass 1 and the inner glass 2 are processed according to the insulating glass production process. In this example, the outer glass 1 is made of double silver Low-e glass, and the inner glass 2 is made of tempered white glass. The outer glass can be processed according to the film removal width of the insulating glass, eliminating the need for more construction width of the film removal, and the inner glass does not need film removal.

[0038] Such as Figure 1 to Figure 3 One of the forms of the inner suspension film combination frame is shown, and the inner suspension film combination frame is added to fix the optical plastic film 3 around the inner...

Embodiment 2

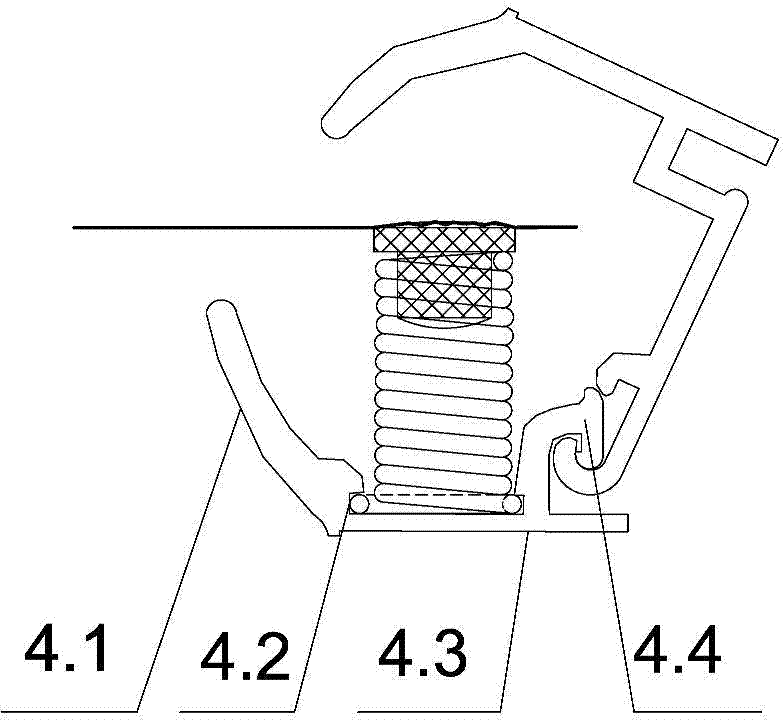

[0045] The main structure of the inner suspended film hollow glass provided in this embodiment is the same as that in Embodiment 1, see figure 1 . Among them, the second form of the inner suspension film combination frame, that is, one of the deformations, the optical plastic film is fixed by the stretch film frame of the obliquely inserted spring assembly, and the compression frame pair spring is replaced by an anti-ultraviolet adhesive strip. Components are decorated, see Figure 5 and Figure 6 ;

[0046] The second form of the inner suspension film combination frame is composed of a stretch film frame and a spring assembly. The stretch film frame includes a bonding bottom plate 4.3, and a decorative end plate 4.1 is arranged on the side of the bonding bottom plate close to the hollow glass cavity. The top of the decorative end plate is a stretch film flange, and the inner side of the decorative end plate and the bonding bottom plate is provided with a slant facing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com