Small-sized mixed-flow pump turbine for low water head pumped storage power station

A pumped-storage power station and pump-turbine technology, applied in the field of hydraulic machinery, can solve the problems of reduced unit efficiency, difficulty in guaranteeing dimensional accuracy, and high construction cost, and achieve high energy recovery efficiency, small flow channel resistance loss, and small amount of civil engineering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

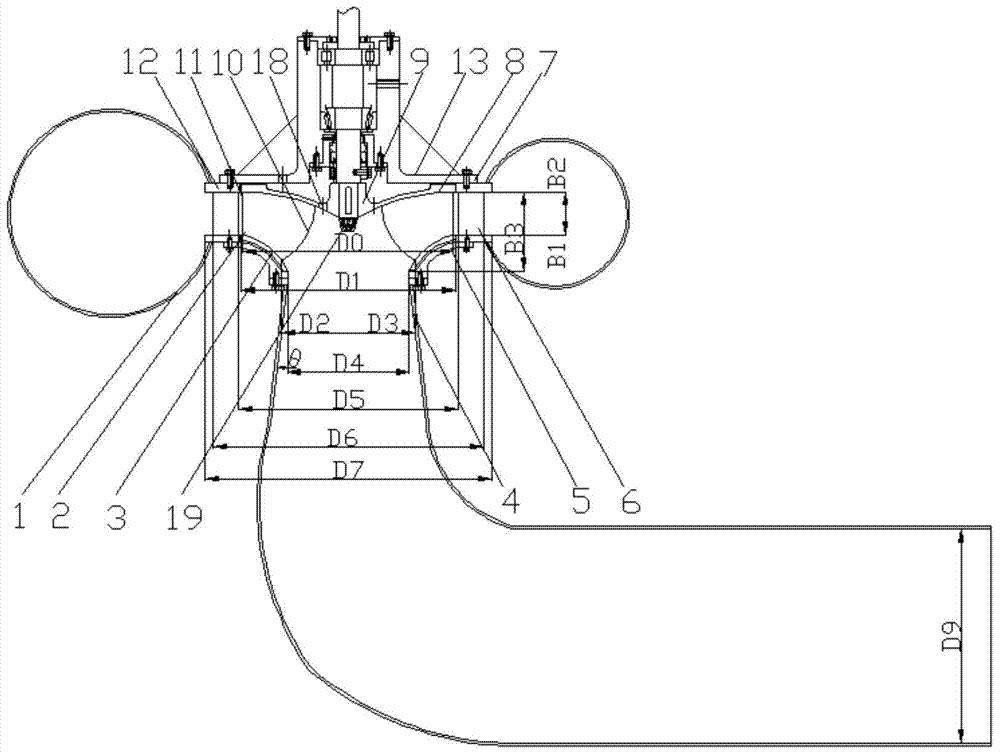

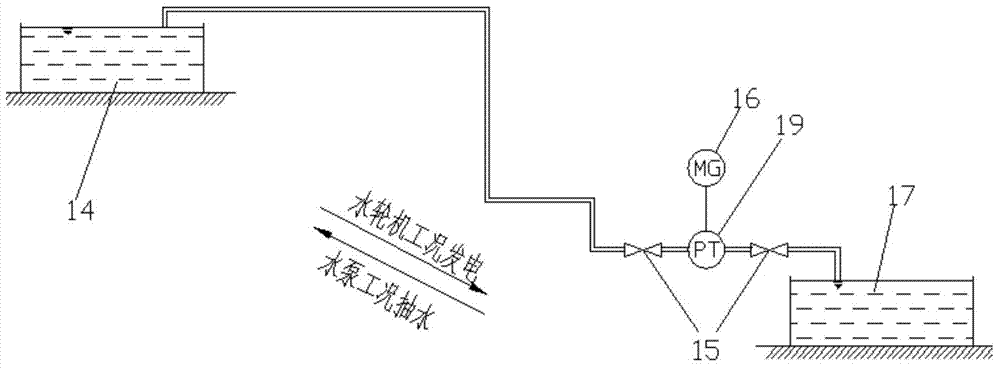

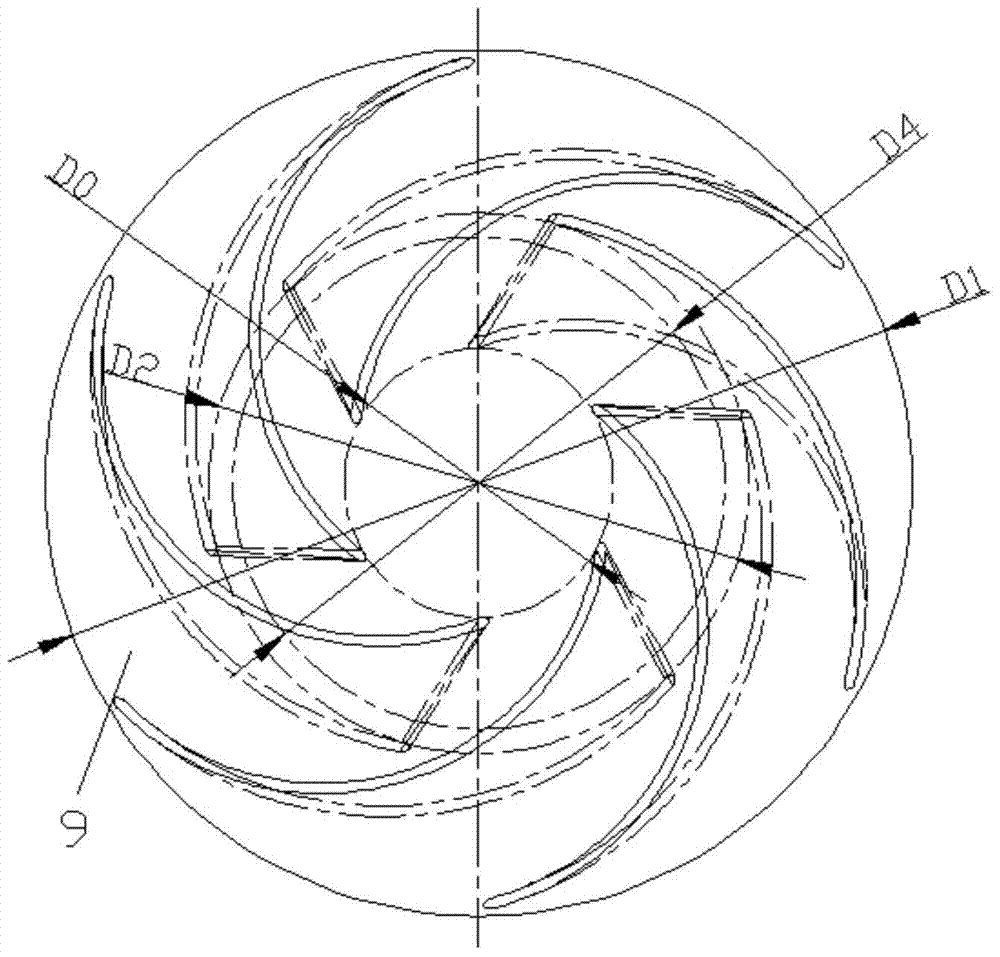

[0019] combine figure 1 , image 3 , Figure 7 , a small Francis pump-turbine used in a low-head pumped storage power station proposed by the present invention, which includes a volute (1), a draft pipe (4), a runner chamber (5), guide vanes (6), an upper Cover (7), runner (9), seat ring (12) and bearing end cover (13), in which: volute (1), guide vane (6), runner (9) and draft tube (4) in sequence connection, the runner (9) includes the runner blade (2), the lower ring (3), the upper crown (8) and the drain cone (19), the upper cover (7) is set on the runner (9), and the bearing end The cover (13) is arranged on the upper cover (7), the wrapping angle of the runner blade (2) is 105°~124°, the water inlet side (11) and the water outlet side (10) of the runner blade (2) The angle between the runner blades (2) is 54°~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Wrap angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com