Electric both-hand rubbing bionic device

A two-handed, electric technology, applied in electromechanical devices, transmission devices, electric components, etc., can solve the problems of high cost, high cost, complex structure, etc., and achieve the effects of high work reliability, widespread use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

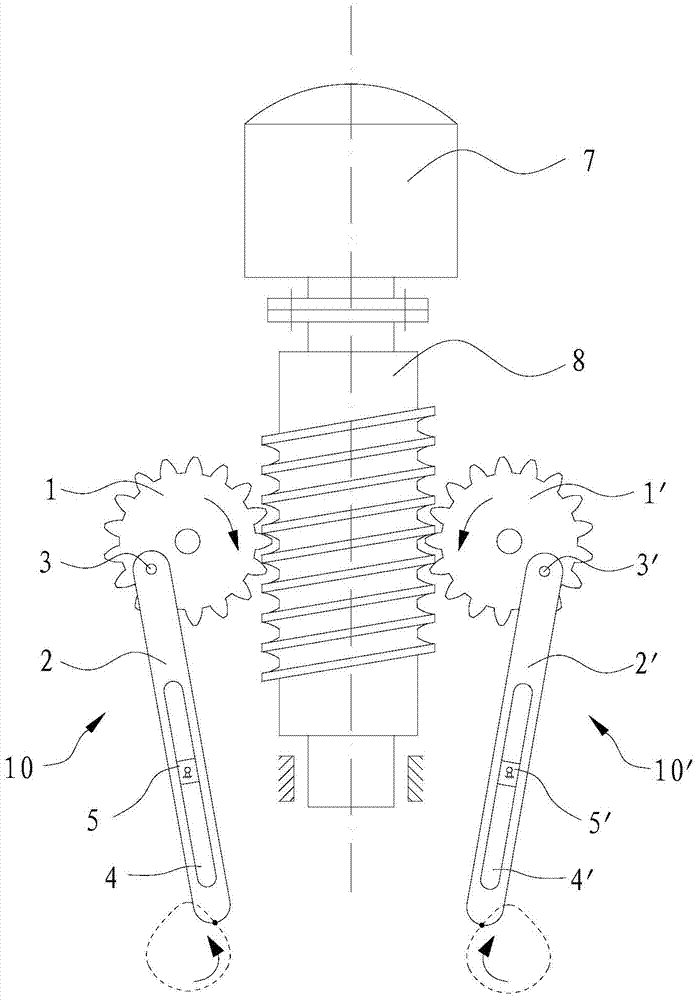

[0025] see figure 1 The shown bionic device for electric hands rubbing includes a frame (not shown in the figure), two sets of rubbing components 10, 10' arranged on the frame,

[0026] The kneading assembly 10 includes a worm wheel 1 rotatably arranged on the frame around the axis, and a connecting rod 2 rotatably arranged on the worm wheel 1 through a pin shaft 3 . There is an eccentric pin hole on the worm wheel 1, the center line of the pin hole is parallel to the axis line of the worm wheel 1, one end of the pin shaft 3 is connected to the upper part of the connecting rod 2, and the other end is rotatably passed through the above pin hole middle. A chute 4 is provided on the connecting rod 2, and the chute 4 extends along the length direction of the connecting rod 2, and the frame is provided with a slider 5 centrally hinged on the frame for providing the guidance of the connecting rod 2, that is, the slider 5 The center positions of the two axial ends of the shaft ...

Embodiment 2

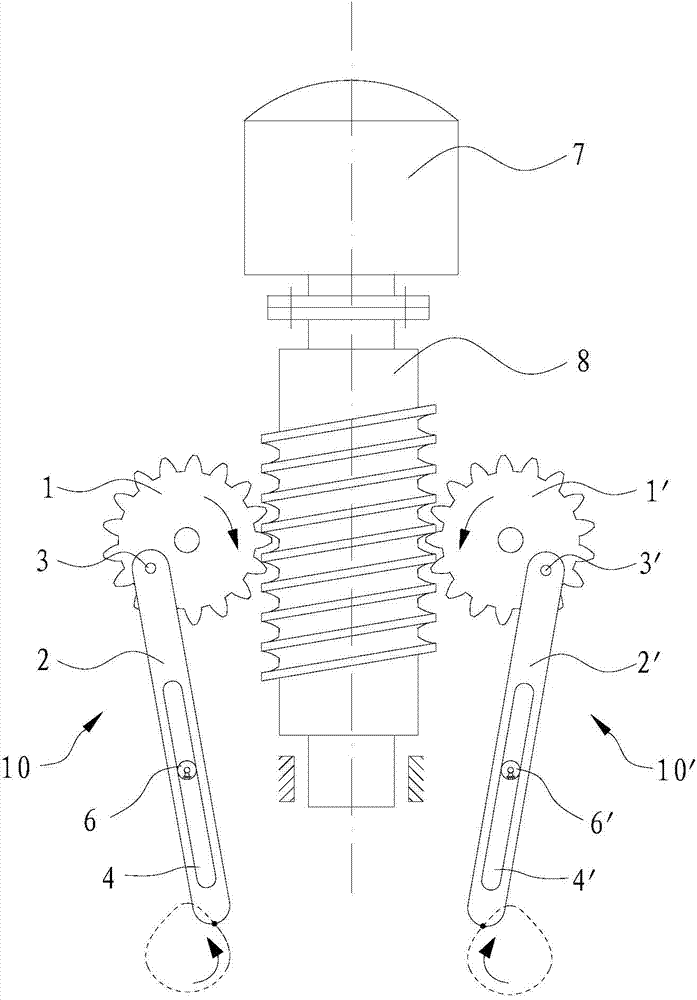

[0035] see figure 2 Shown is a kind of bionic device for electric hands rubbing, the difference between this bionic device and embodiment 1 mainly lies in the setting of the parts that provide connecting rod 2, 2' guide. In this embodiment, the guide member 6, 6' provided on the frame is centered on the part providing the guide of the connecting rod 2, 2', and the guide member 6, 6' is respectively arranged in the chute 4, 4' with loose fit. Among them, the circumferential outer surface of the guides 6, 6' matched with the longitudinal groove walls of the chute 4, 4' is a cylindrical surface, and the guides 6, 6' form a plane height pair with the chute 4, 4' respectively. When the worm 8 rotates to drive the worm gear 1 and the worm gear 1' to rotate, the connecting rods 2 and 2' respectively move linearly and swing, so that the lower ends of the connecting rods 2, 2' can produce a bionic motion similar to rubbing hands.

[0036] During the above movement process, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com