Signal cable

A signal cable and cable core technology, applied in the field of signal cables with new structure, can solve the problem of train safety factor threat, can not be shielded from interference sources, etc., achieve strong shielding performance, ensure electrical stability and moisture resistance, excellent aging resistance Effects of performance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

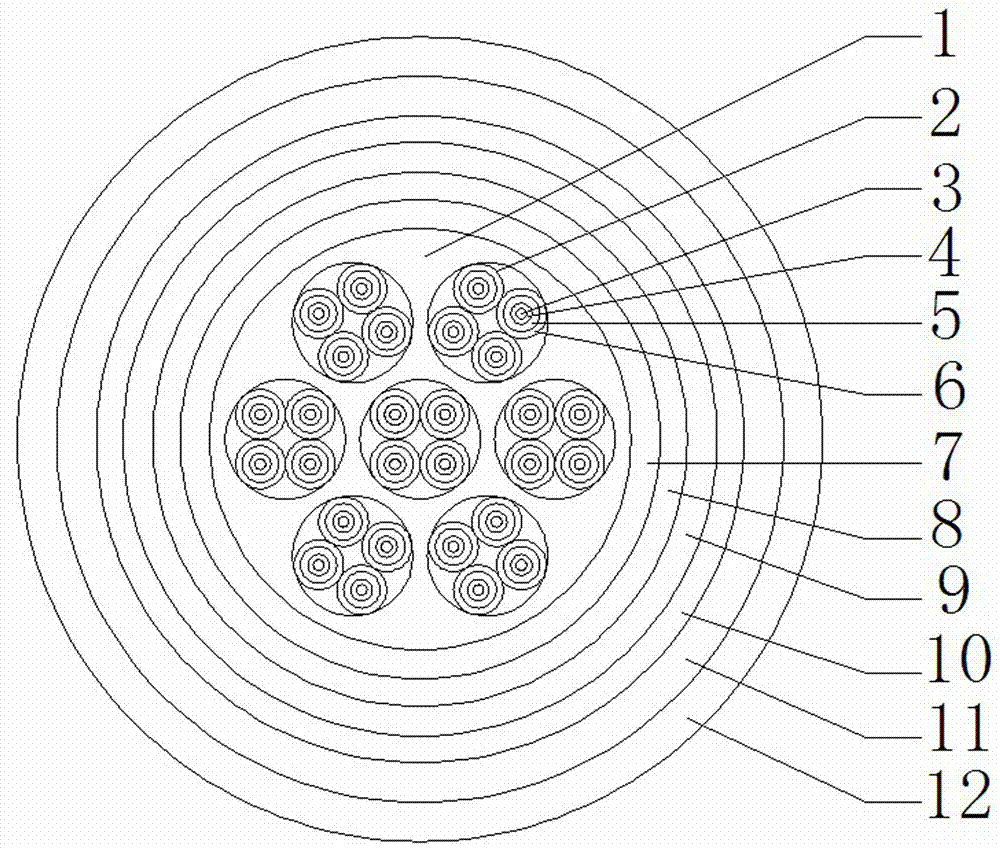

[0018] figure 1 A signal cable is shown, comprising a cable core 1 and an outer sheath 12 coated outside the cable core 1, the cable core 1 is provided with a non-hygroscopic insulating layer 7, and the non-hygroscopic insulating layer 7 is longitudinally Covered with a comprehensive sheath 8, the comprehensive sheath 8 is provided with a welded pipe aluminum sheath 9, and the welded pipe aluminum sheath 9 is provided with a polyethylene adhesive sheath 10, and the polyethylene adhesive sheath 10 and Double steel tape armor layers 11 are arranged between the outer sheaths 12 .

[0019] The cable core 1 is provided with several pairs of wire groups or quadruple wire groups. The pair of wire groups is formed by twisting two insulated single wires 2 of different colors, and the quadruple wire group is formed by twisting four insulated single wires 2 of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com