Oil-immersed transformer for wind turbine system

A technology for wind power generation systems and oil-immersed transformers, applied in the field of power transformers, can solve the problems of increasing the volume of transformers in wind power generation systems, inconvenient transformer safety protection and wiring, and increasing operating costs of wind power generation systems, achieving compact structure, The effect of small footprint and convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

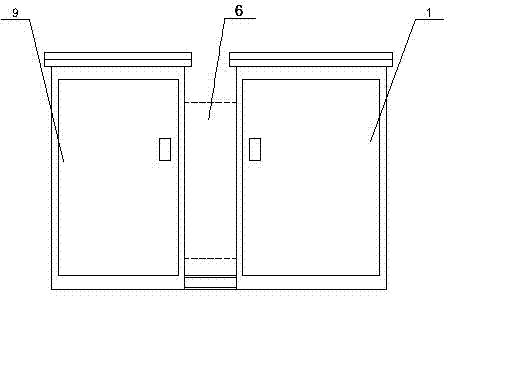

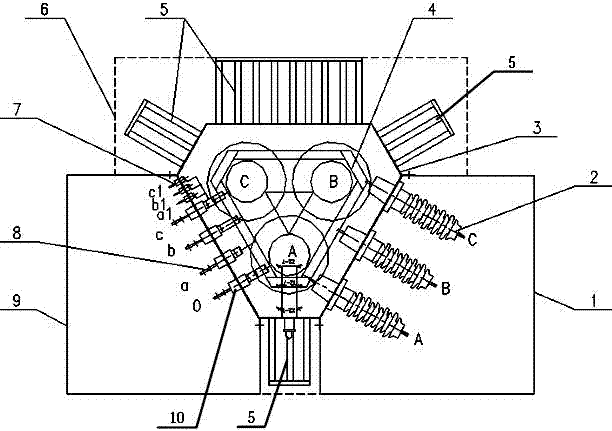

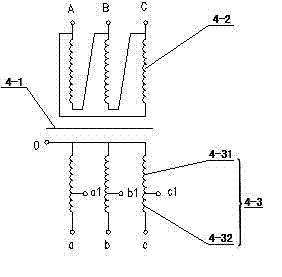

[0028] see Figure 1 to Figure 5 : the present invention comprises fuel tank 3, device body 4, high pressure chamber 1, low pressure chamber 9 and radiator 5.

[0029] Wherein, the oil tank 3 is used to hold the transformer oil, and the device body 4 is installed. The horizontal section of the oil tank 3 is in the shape of a hexagon, and has three long sides of equal length. The short sides, these three short sides are connecting plates 3-4, and the three connecting plates 3-4 are respectively spaced between the high-voltage side panel 3-1, the low-voltage side panel 3-2 and the heat dissipation panel 3-3, that is, the three of the fuel tank 3 The long side and the three short sides are surrounded by each other, and the angle between the two long sides is 60° (equivalent to an equilateral triangle after chamfering). 120° rotational symmetry. A high-voltage bushing 2 is installed on the high-voltage side panel 3-1 of the fuel tank 3, and the high-voltage bushing 2 is connect...

Embodiment 2

[0034] The other structures of this embodiment are the same as those of Embodiment 1, the difference lies in: the horizontal section structure of the oil tank and the horizontal section structure of the high and low pressure chambers.

[0035] The horizontal section of the fuel tank is in the shape of an equilateral triangle, with each angle being 60° to form a high-pressure side panel, a low-pressure side panel and a heat dissipation panel. The horizontal section of the fuel tank is both axisymmetric and rotationally symmetric with a rotation angle of 120°.

[0036] The horizontal cross-sectional shapes of the high-pressure chamber and the low-pressure chamber are the same, which are respectively a right-angled trapezoidal shape, and the hypotenuses correspond to the respective assembly panels on the fuel tank.

[0037] The above-mentioned two embodiments are only two preferred specific technical solutions of the present invention, and the present invention can also make other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com