Antistatic structure of array substrate

An array substrate, anti-static technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve problems affecting product quality, electrostatic damage, etc., to achieve the effects of avoiding electrostatic damage, improving product quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0032] The present invention is described in the VA display mode, but is not limited to the VA display mode.

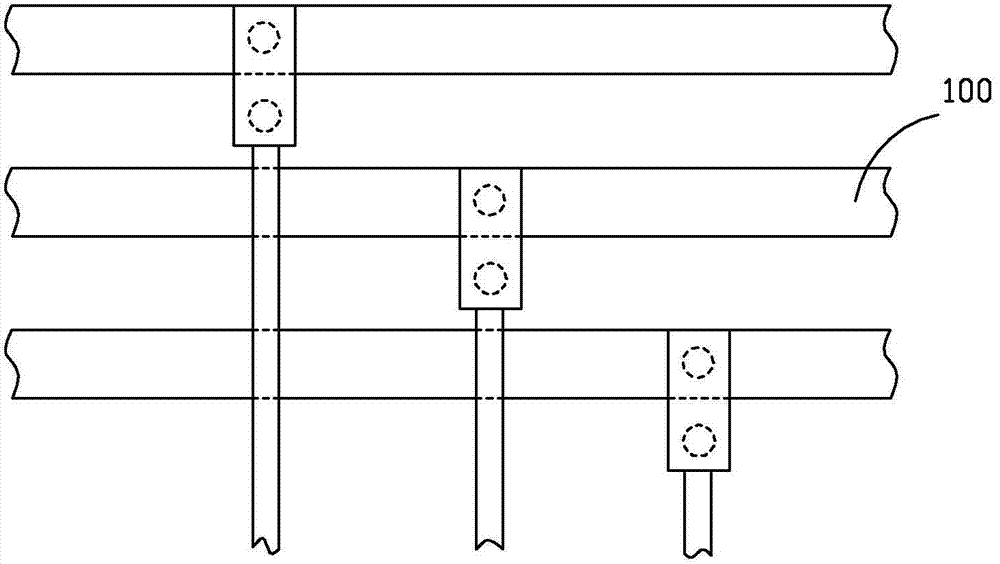

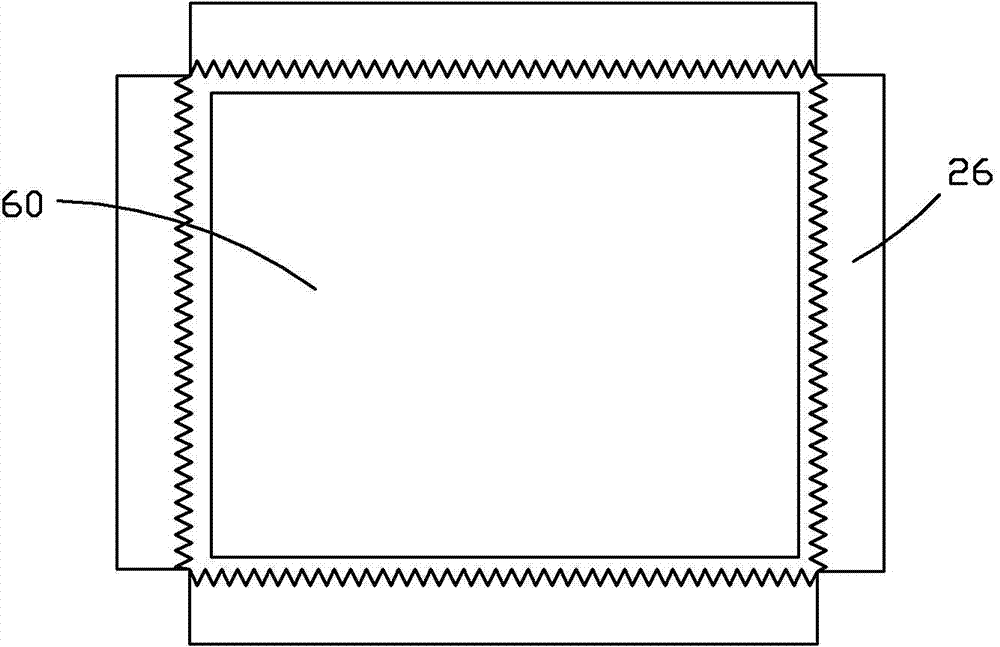

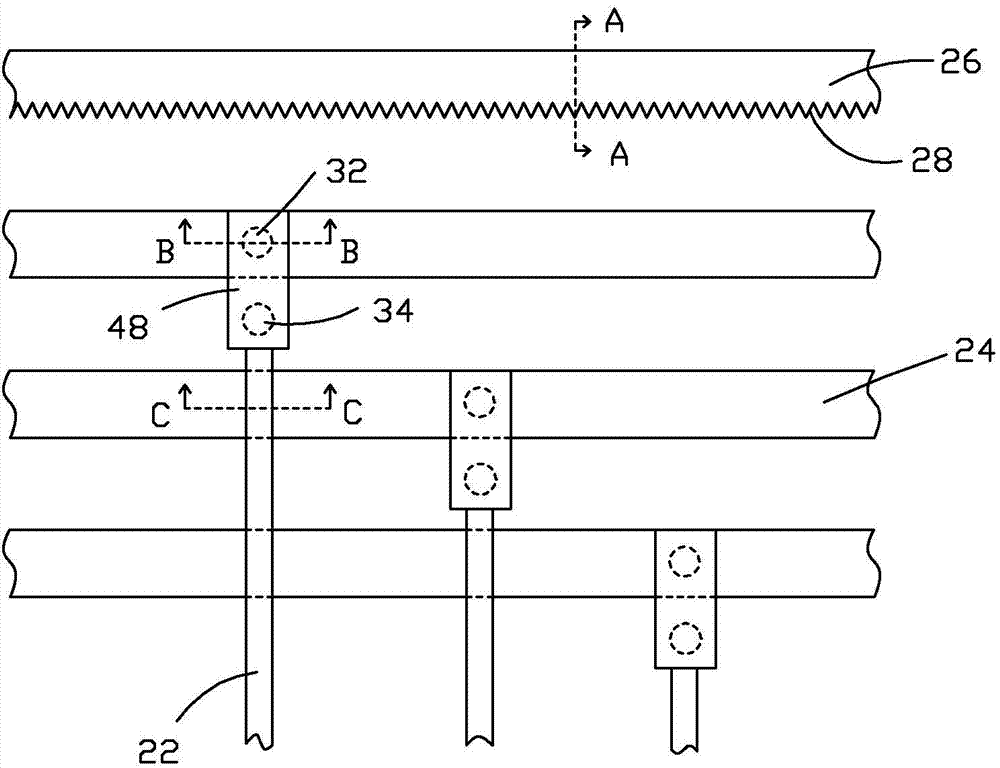

[0033] The present invention is to pattern imaginary lines parallel to the short-circuit bar next to the short-circuit bar during the fabrication of the array substrate, that is, the present invention provides an anti-static structure for the array substrate. Please refer to figure 2 and image 3 , specifically including: an active area 60 of the array substrate and several imaginary lines 26 surrounding the effective area 60, the active area 60 of the array substrate is provided with several signal lines 22 and electrically connected to the several signal lines 22 respectively. Several shorting bars 24, the imaginary lines 26 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com