Environmental protection type low noise extrusion structure for separating water and sludge

An environment-friendly, water-separating technology, applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as poor stability, pollution of force-applying devices, loud noise, etc., achieve fast compression and stretching speed, and avoid noise , the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

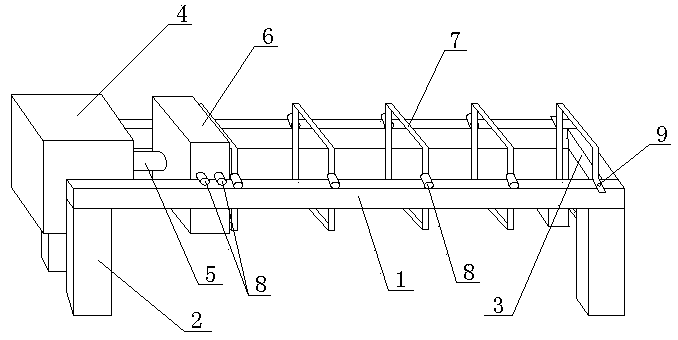

[0019] Such as figure 1 As shown, this embodiment includes two cross bars 1 parallel to each other and four columns 2 supporting the two cross bars 1, one end of the two cross bars 1 is fixedly connected by a cross plate 3, and the other ends of the two cross bars 1 The cylinder 4 is fixed, and the front end of the piston rod 5 of the cylinder 4 is fixed with a top plate 6. At least one roller 8 is arranged on each side of the top plate 6. The top plate 6 is stuck between two cross bars 1 through the rollers 8 on both sides. .

[0020] Several brackets 7 are arranged between the two cross bars 1 of the present embodiment, the bracket 7 closest to the cross plate 3 is fixed on the cross bar 1 by bolts 9, and two rollers 8 are arranged on each other bracket 7, The bracket 7 is clamped between the two cross bars 1 by the roller 8, and the bracket 7 closest to the top plate 6 is fixedly connected with the top plate 6 .

[0021] The shape of the bracket 7 in this embodiment is sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com