Cutting blade and milling tool using same

A technology for cutting blades and blades, which is applied in the manufacture of tools, milling cutters, and milling machine equipment. It can solve the problems of limited profiling cutting capabilities, difficult control of cutting edge vibration, and difficulty in ensuring processing quality, so as to achieve small processing vibration and smooth processing. Both accessibility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

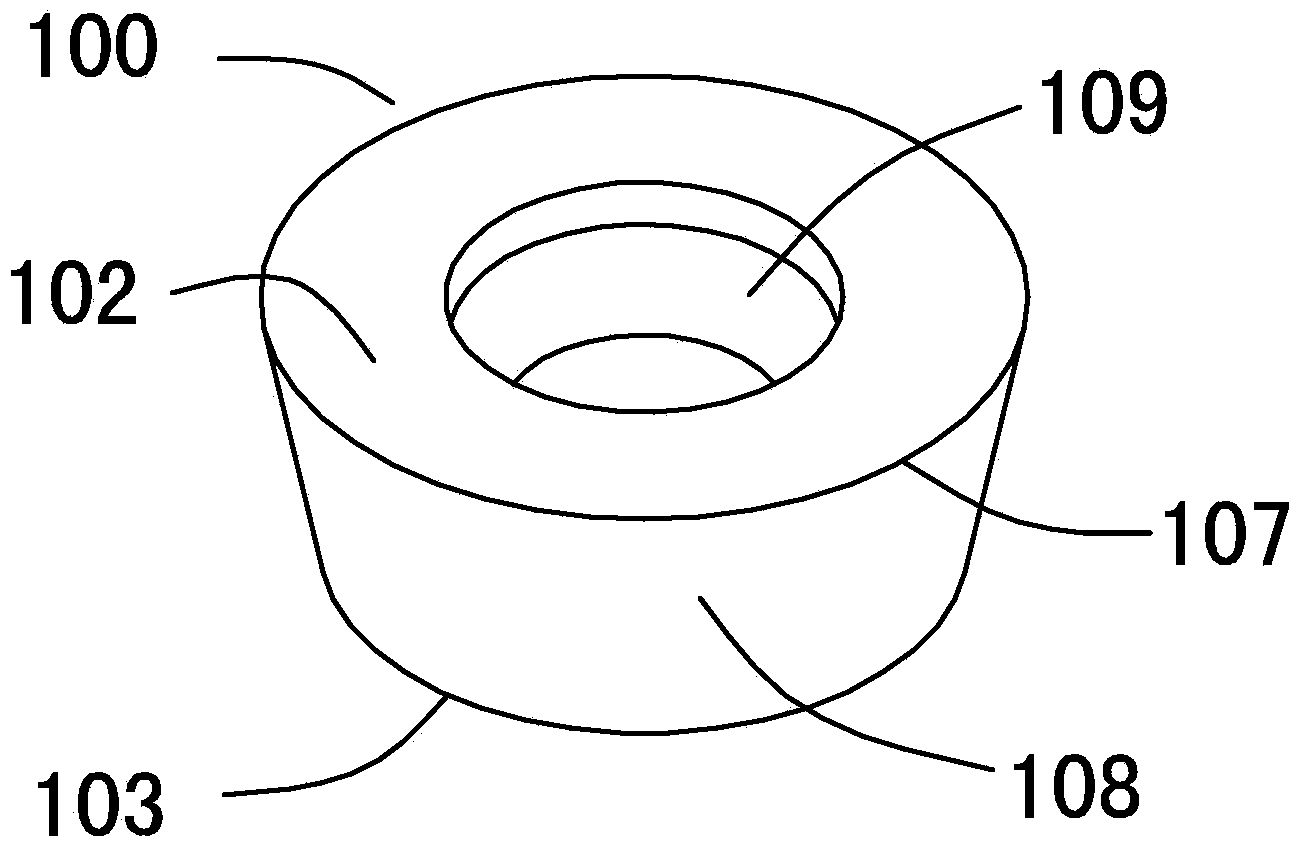

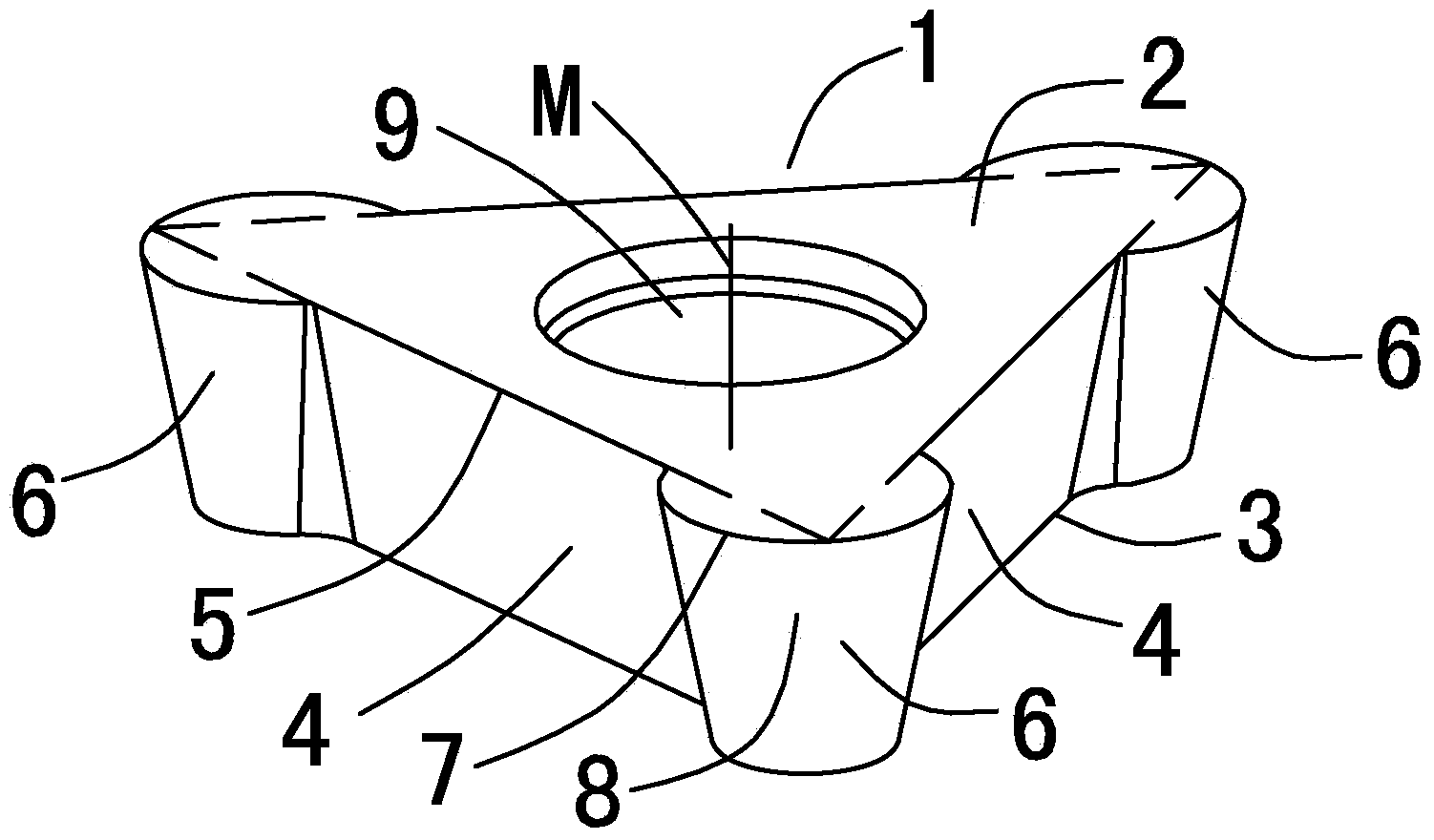

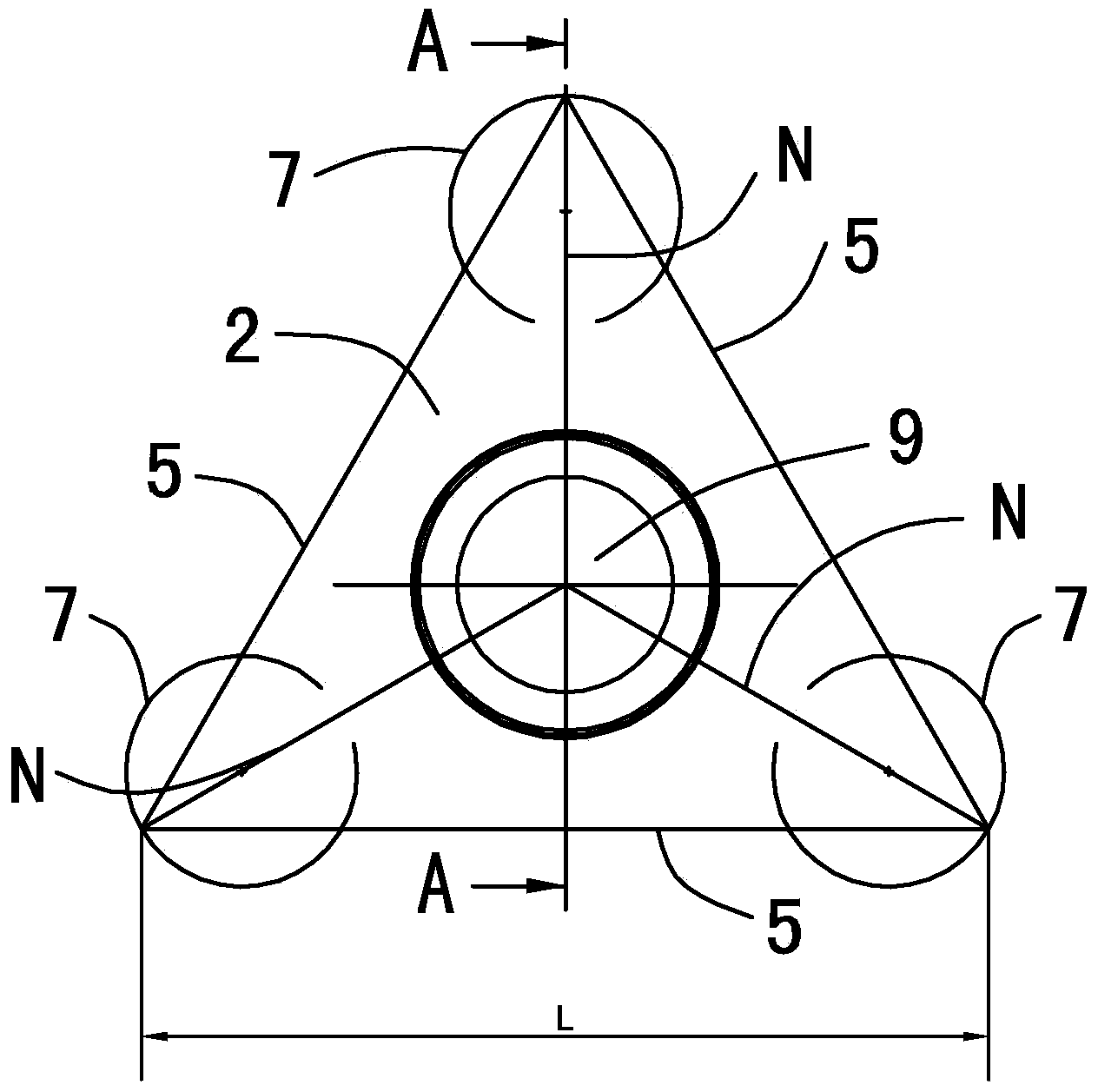

[0035] see Figure 2 to Figure 8 As shown, a kind of cutting insert of the present invention, this cutting insert forms positive type insert body 1 with hard material such as cemented carbide, and its shape is slightly equilateral triangular plate shape, and wherein upper surface 2 and lower surface 3 are parallel to each other, and lower surface 3 as a support surface, the side 4 connects the upper surface 2 and the lower surface 3, and the side 4 intersects with the upper surface 2 to form three perimeters 5. In the center of the upper surface 2 and the lower surface 3, a blade body 1 is formed vertically along the thickness direction. The installation hole 9 passing through the upper surface and the lower surface 3 forms an arc portion 14 on the installation hole 9, and the arc portion 14 is a contact area where the tapered portion of the clamping screw 11 presses the cutting insert. In addition, an outwardly protruding arcuate portion 6 relative to the insert mounting hole...

Embodiment 2

[0039] see Figure 9 to Figure 12 As shown, a cutting insert of the present invention differs from Embodiment 1 in that the side surface 4 and the upper surface 2 form an included angle α=90°, and the flank 8 of the cutting edge forms an angle with the upper surface 2 The included angle β=90°, the arc convex part also intersects with the lower surface to form a second arc-shaped cutting edge 71 protruding outward relative to the periphery, and each of the second arc-shaped cutting edges 71 passes through the lower surface 3 Corresponding vertices of the equilateral triangle formed by the line of intersection with the side and its extension. Like this, this cutting blade just has three first circular-arc cutting edges 7 and three second circular-arc cutting edges 71, and the shape structure of the first circular-arc cutting edge 7 and the second circular-arc cutting edge 71 same. Taking the first arc-shaped cutting edge 7 as an example, the chip breaker near the first arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com