Device and technology for welding aluminum alloy plate

A welding device and aluminum alloy plate technology, which is applied in the field of aluminum alloy welding, can solve the problems of moving position and poor welding effect, and achieve the effects of good controllability, good welding effect and high structural strength of the weldment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

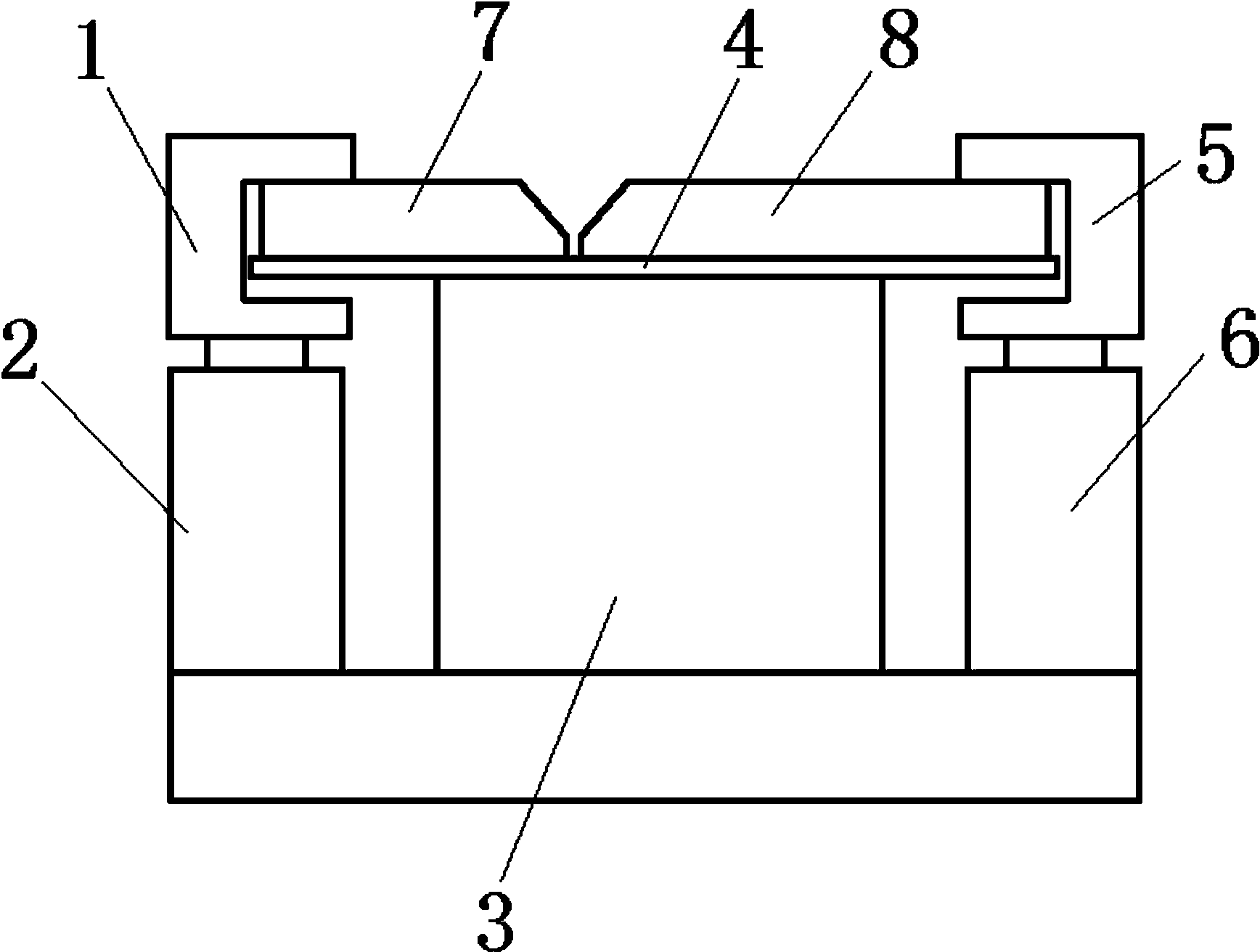

[0012] This embodiment provides an aluminum alloy plate welding device, which is characterized in that: the aluminum alloy plate welding device includes a left electromagnet core 1, a left electromagnet coil 2, a frame 3, a supporting plate 4, and a right electromagnet core 5 , left electromagnet coil 6;

[0013] Wherein: the left electromagnet coil 2 and the left electromagnet coil 6 are installed on the left and right sides of the frame 3, the supporting plate 4 is installed on the top of the frame 3, the left aluminum plate 7 and the right aluminum plate 8 to be welded are placed on the supporting plate 4, the left The sides of the electromagnet core 1 and the right electromagnet core 5 each have a groove for clamping the left aluminum plate 7 and the right aluminum plate 8 .

[0014] A welding process using the aluminum alloy plate welding device is characterized in that: a manual argon tungsten arc welding process is adopted, and after the welded left aluminum plate 7 and...

Embodiment 2

[0016] This embodiment provides an aluminum alloy plate welding device, which is characterized in that: the aluminum alloy plate welding device includes a left electromagnet core 1, a left electromagnet coil 2, a frame 3, a supporting plate 4, and a right electromagnet core 5 , left electromagnet coil 6;

[0017] Wherein: the left electromagnet coil 2 and the left electromagnet coil 6 are installed on the left and right sides of the frame 3, the supporting plate 4 is installed on the top of the frame 3, the left aluminum plate 7 and the right aluminum plate 8 to be welded are placed on the supporting plate 4, the left The sides of the electromagnet core 1 and the right electromagnet core 5 each have a groove for clamping the left aluminum plate 7 and the right aluminum plate 8 .

[0018] A welding process using the aluminum alloy plate welding device is characterized in that: a manual argon tungsten arc welding process is adopted, and after the welded left aluminum plate 7 and...

Embodiment 3

[0020] This embodiment provides an aluminum alloy plate welding device, which is characterized in that: the aluminum alloy plate welding device includes a left electromagnet core 1, a left electromagnet coil 2, a frame 3, a supporting plate 4, and a right electromagnet core 5 , left electromagnet coil 6;

[0021] Wherein: the left electromagnet coil 2 and the left electromagnet coil 6 are installed on the left and right sides of the frame 3, the supporting plate 4 is installed on the top of the frame 3, the left aluminum plate 7 and the right aluminum plate 8 to be welded are placed on the supporting plate 4, the left The sides of the electromagnet core 1 and the right electromagnet core 5 each have a groove for clamping the left aluminum plate 7 and the right aluminum plate 8 .

[0022] A welding process using the aluminum alloy plate welding device is characterized in that: a manual argon tungsten arc welding process is adopted, and after the welded left aluminum plate 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com