Bag lifting, patting and supporting mechanism

A technology of bag support and lifting device, which is applied in the direction of solid materials, packaging, and the type of packaged items. It can solve the problems that the bag support board does not have power, the bag is prone to tilting, and the vibration is low. It has a simple structure, is not easy to tilt, and The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

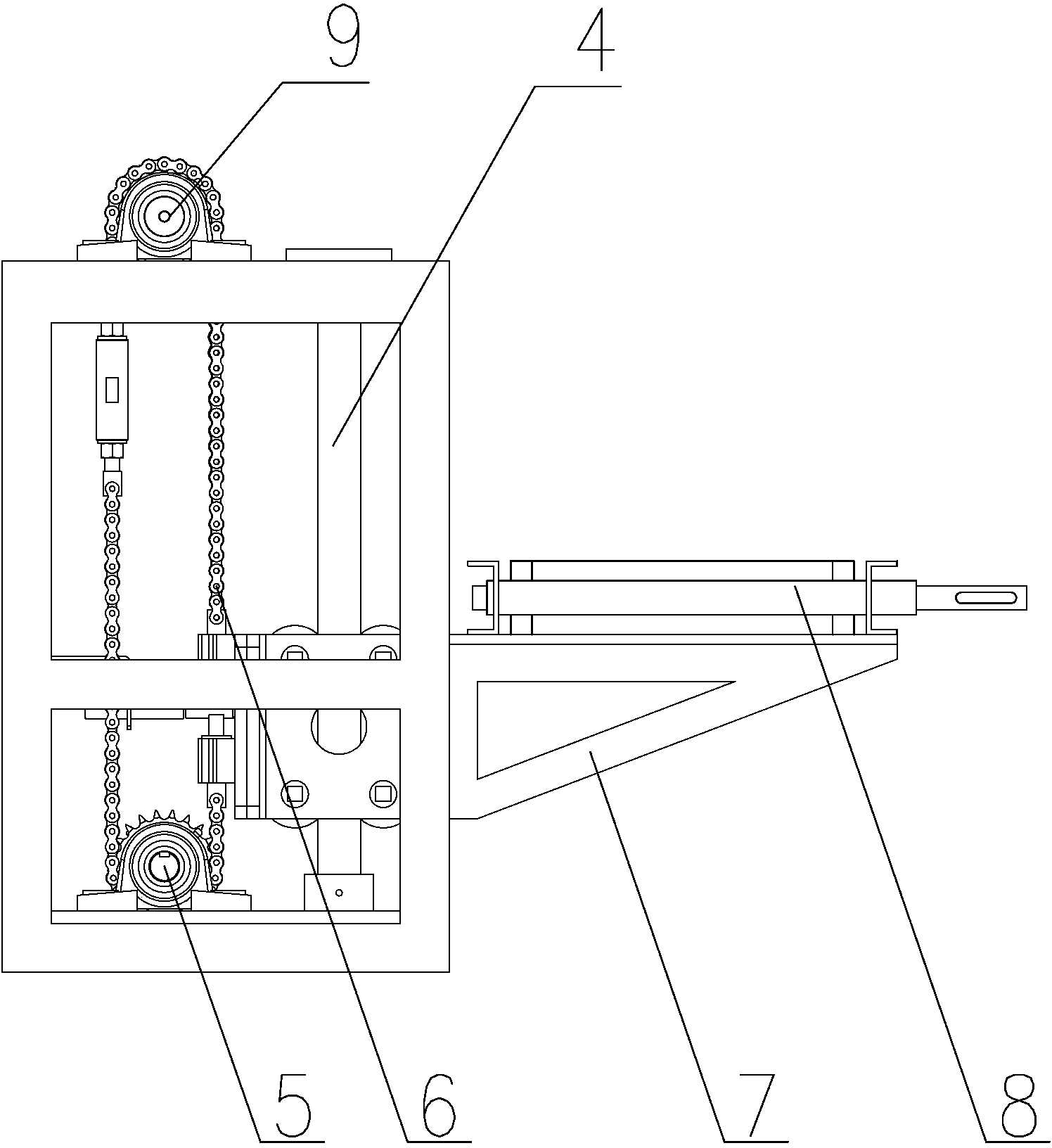

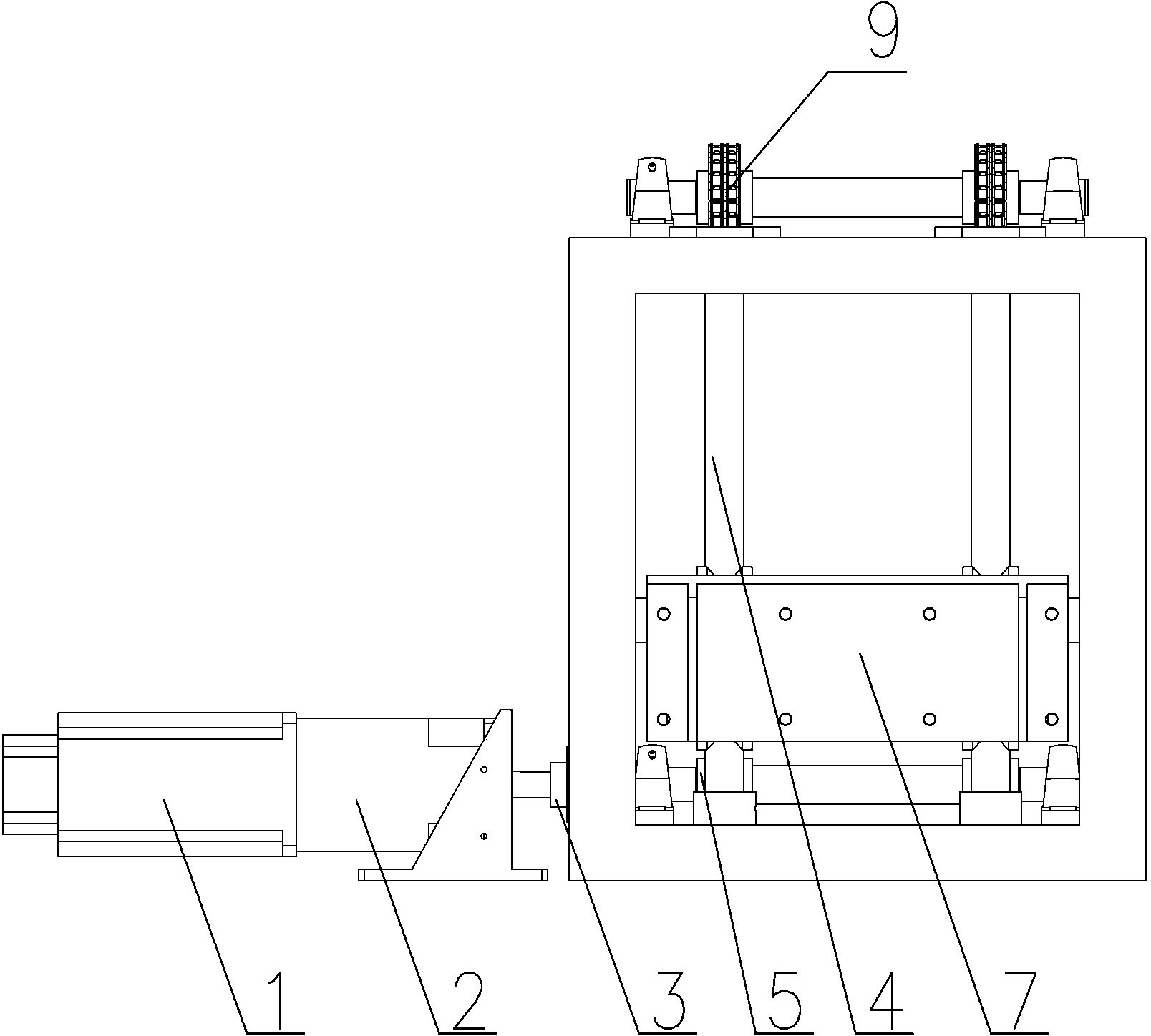

[0012] see figure 1 , 2 , the elevating and flapping bag-holding mechanism, comprising a bag-holding plate 8, the bag-holding plate 8 is installed on the bracket 7 of a lifting device; The shaft coupling 3 is connected with the reducer 2 installed on the servo motor 1, the upper part of the frame is provided with a driven sprocket 9, and the driving sprocket 5 and the driven sprocket 9 are connected by a precision roller chain 6; the frame is also provided with There is a pair of vertical guide posts 4, one side of the bracket 7 is fixed on the guide posts 4 by the guide wheels, and can move up and down along the guide posts 4; the edge of the bracket 7 is fixed on the precision roller chain 6.

[0013] The main feature of this mechanism is to improve the up and down reciprocating movement of the bag holder plate (a 3mm thick steel plate) driven by the cylinder to the up and down reciprocation movement of the bag holder plate 8 driven by the servo motor 1 to vibrate the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com