Preparation method of reinforced polypropylene foamed beads

A foamed bead and polypropylene technology, which is applied in the field of polypropylene foamed bead preparation, can solve the problems of lower crystallinity, cumbersome process control, and insufficient fineness of spherulites, achieve high strength, save steam, and be completely reliable. Effect of Recycling Preparation Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

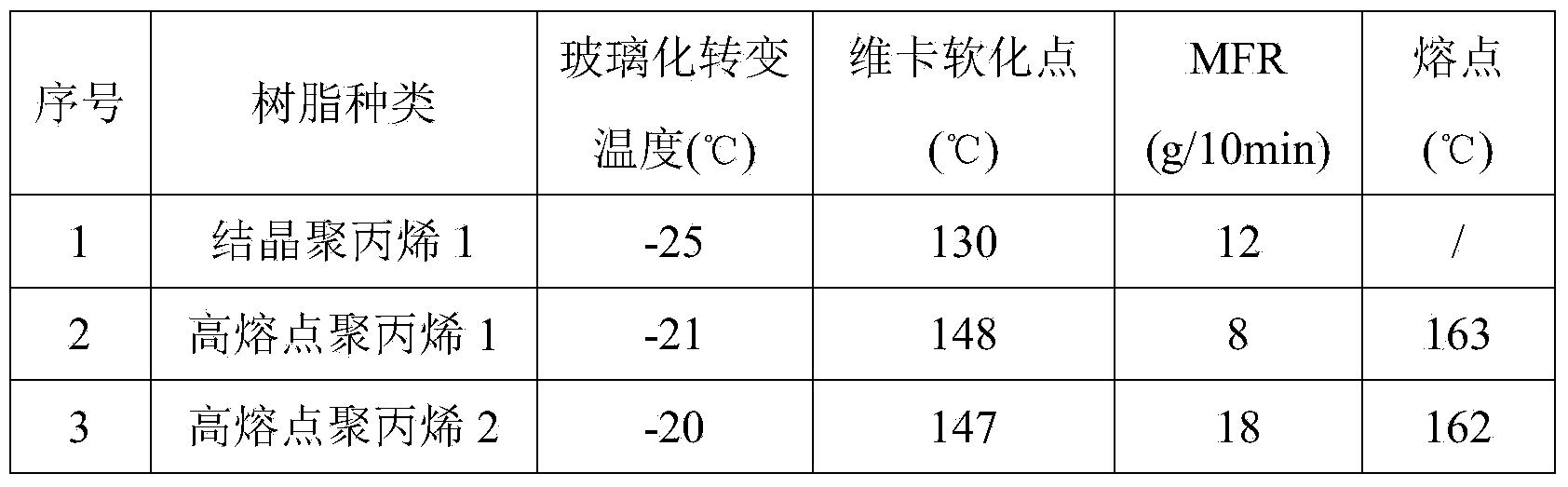

[0028] Implementation case: Table 1

[0029]

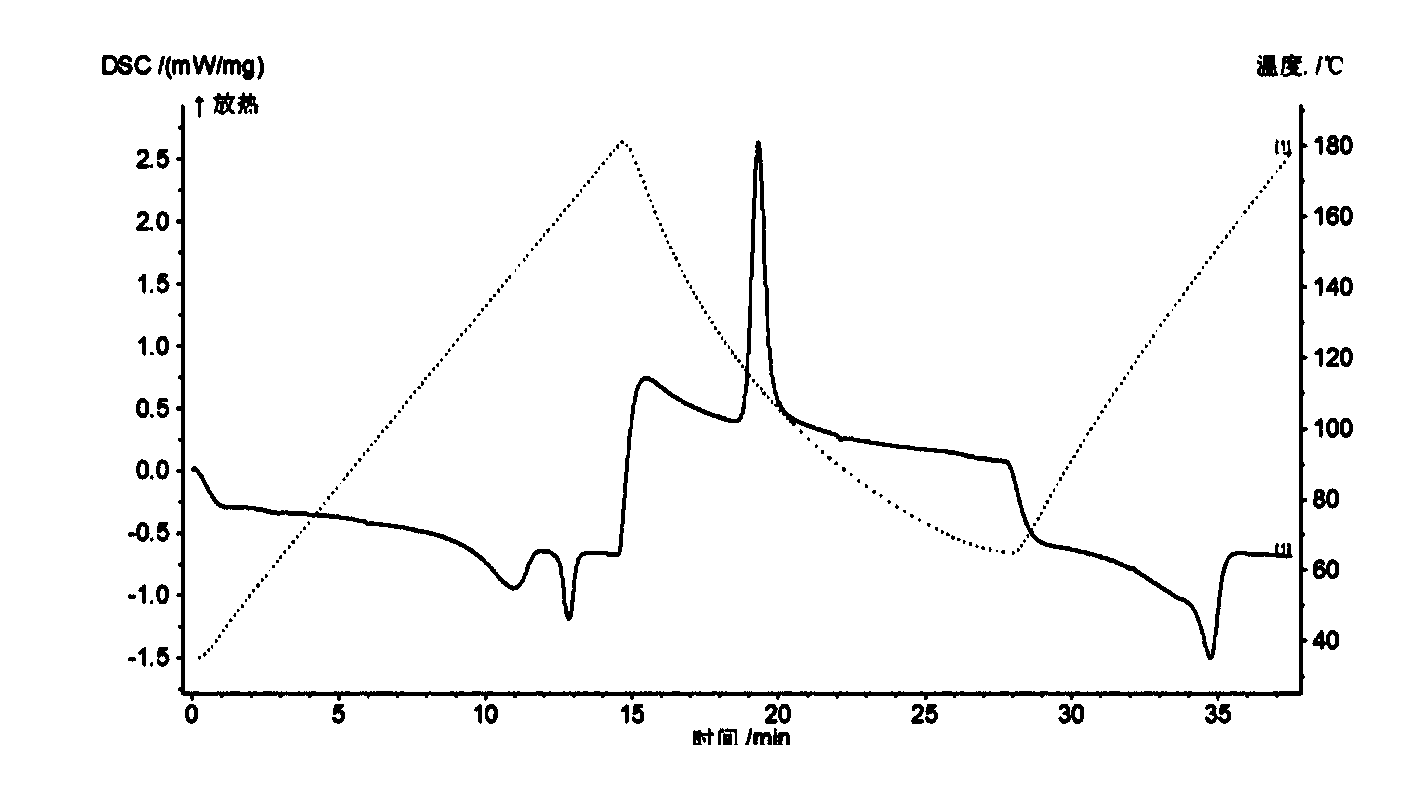

[0030] Table 1 shows the basic performance parameters of different types of polypropylene used.

[0031] Crystalline polypropylene, such as the use of binary copolymerized PP, has the above-mentioned effects (PP polymer obtained by co-polymerizing propylene monomer with a small amount of ethylene monomer), which reduces the crystal orientation of PP and improves the impact resistance of the polymer especially at low temperature performance. The same is true for ternary.

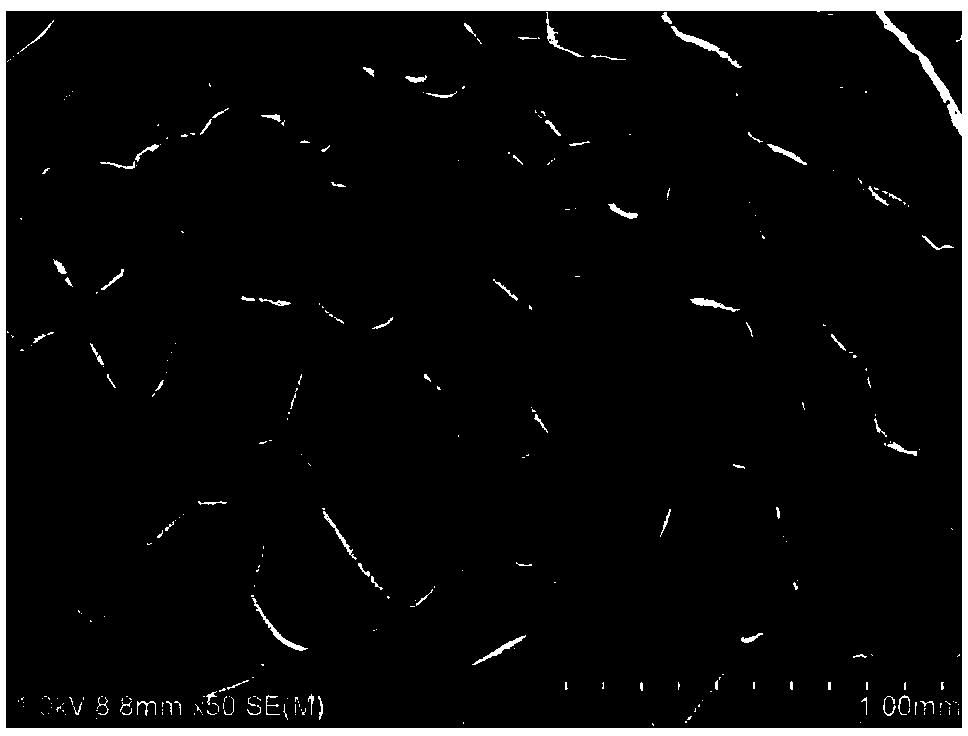

[0032] The diameters of the above crystalline nucleating agent particles are mainly distributed in the range of 0.8-1.2 μm, accounting for more than 80% of the total weight. The main distribution of diameters should preferably not exceed 1.8 μm.

[0033] Table II:

[0034]

[0035] Table 2 shows the parameters of EPP particles (especially crystalline polypropylene). In the mixed type, the mass of crystalline polypropylene 1 accounts for about 80%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com