Sheet-like magnetic infrared pigment and preparation method thereof

A technology of infrared pigments and magnetic pigments, applied in the direction of fibrous fillers, inorganic pigment treatment, chemical instruments and methods, etc., can solve problems such as delamination, poor friction resistance, and inks that cannot achieve printing effects, and achieve wide application Value, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

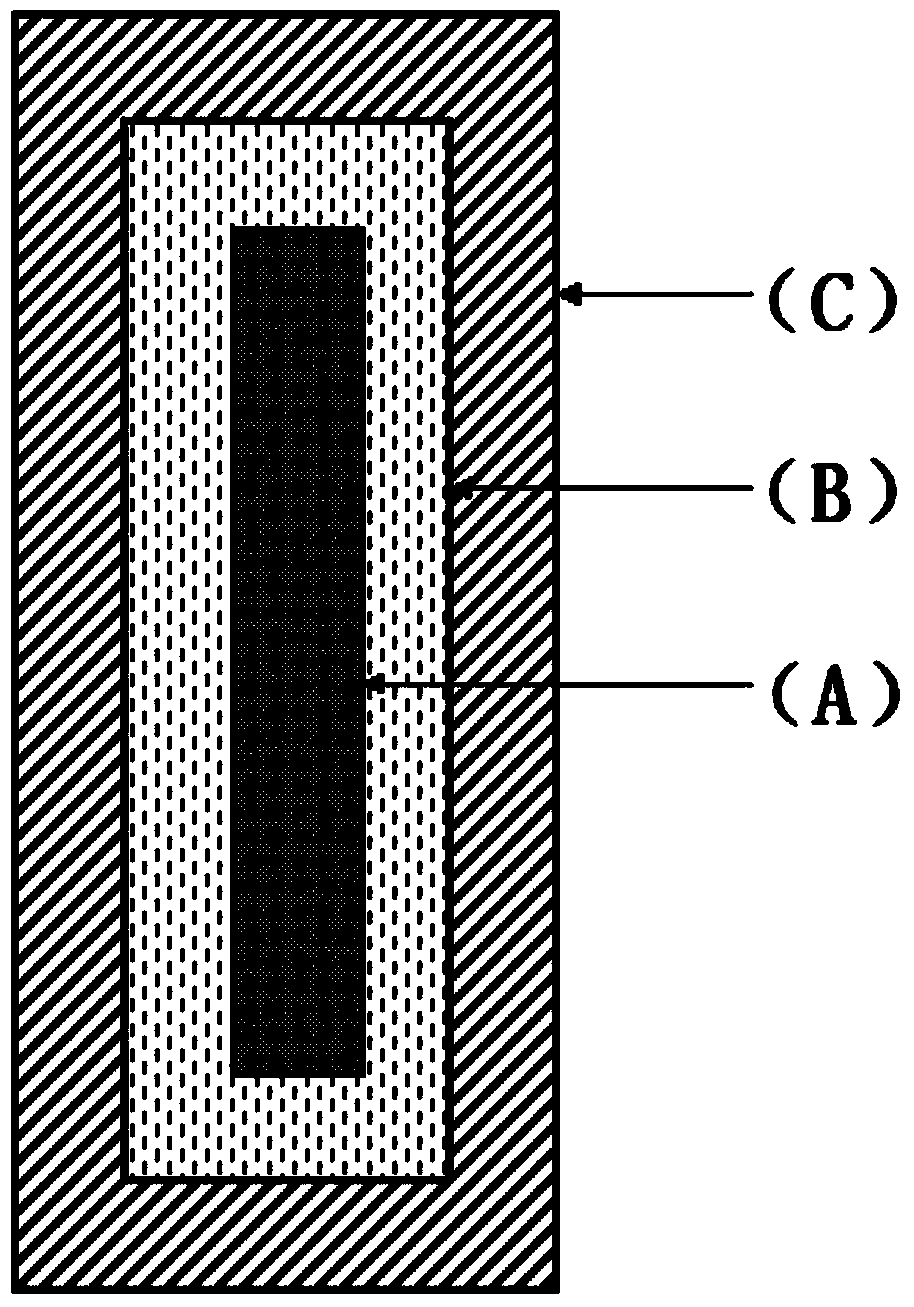

Image

Examples

Embodiment 1

[0027] An embodiment of a flaky magnetic infrared pigment of the present invention, the flaky magnetic infrared pigment described in this embodiment is prepared by the following method:

[0028] (1) Take 50g of flaky magnetic powder, put it in a four-necked flask, add 1L of 0.5% ammonium fluoride aqueous solution, stir and raise the temperature to 50°C, after 0.5h of treatment, put it into the suction filtration tank, and suction and wash it into the filtrate The fluoride ion concentration is less than 50ppm, and the pretreated flaky magnetic powder is obtained;

[0029] (2) Add 50g of flaky magnetic powder obtained in step (1) and 750mL of deionized water into a four-neck flask, stir and raise the temperature to 80°C, adjust the pH value to 7.0, and add 20g / L of AlCl dropwise at a rate of 40mL / h 3 Solution 10mL, and at the same time adjust with 10% NaOH solution to maintain a stable pH value, keep stirring for 2 hours after feeding, then filter with suction, wash with deioniz...

Embodiment 2

[0034] An embodiment of a flaky magnetic infrared pigment of the present invention, the flaky magnetic infrared pigment described in this embodiment is prepared by the following method:

[0035] (1) Take 50g of flaky magnetic powder, put it in a four-necked flask, add 1L of 0.01% potassium hydroxide aqueous solution, stir and raise the temperature to 20°C, after 2 hours of treatment, put it into a suction filtration tank, and suction and wash until the hydrogen in the filtrate Oxygen ion concentration is less than 50ppm to obtain pretreated flaky magnetic powder;

[0036] (2) Add 50g of flaky magnetic powder obtained in step (1) and 1000mL of deionized water into a four-neck flask, stir and raise the temperature to 60°C, adjust the pH to 8.0, and add 50g / L of AlCl dropwise at a rate of 40mL / h 3 Solution 12.5mL, and at the same time adjust with 10% NaOH solution to maintain a stable pH value, keep stirring for 3 hours after feeding, then filter with suction, wash with deionized...

Embodiment 3

[0040] An embodiment of a flaky magnetic infrared pigment of the present invention, the flaky magnetic infrared pigment described in this embodiment is prepared by the following method:

[0041] (1) Take 50g of flaky magnetic powder, put it in a four-necked flask, add 1L of 0.6% sodium hydroxide aqueous solution, stir and raise the temperature to 80°C, put it into a suction filtration tank after treatment for 1 hour, and suction and wash until the hydrogen in the filtrate Oxygen ion concentration is less than 50ppm to obtain pretreated flaky magnetic powder;

[0042] (2) Add 50g of flaky magnetic powder obtained in step (1) and 900mL of deionized water into a four-neck flask, stir and raise the temperature to 90°C, adjust the pH to 4.0, and drop 30g / L of silicon at a rate of 40mL / h NaOH solution 2.5mL, and at the same time adjust with 10% NaOH solution to maintain a stable pH value, keep stirring for 1 hour after feeding, then filter with suction, wash with deionized water fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com