Resin composition for ultraviolet curable adhesive and adhesive

A resin composition and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, polyurea/polyurethane adhesives, etc. Adhesive can not be filled and other problems, to achieve the effect of excellent step followability, excellent whitening resistance, excellent adhesion and retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

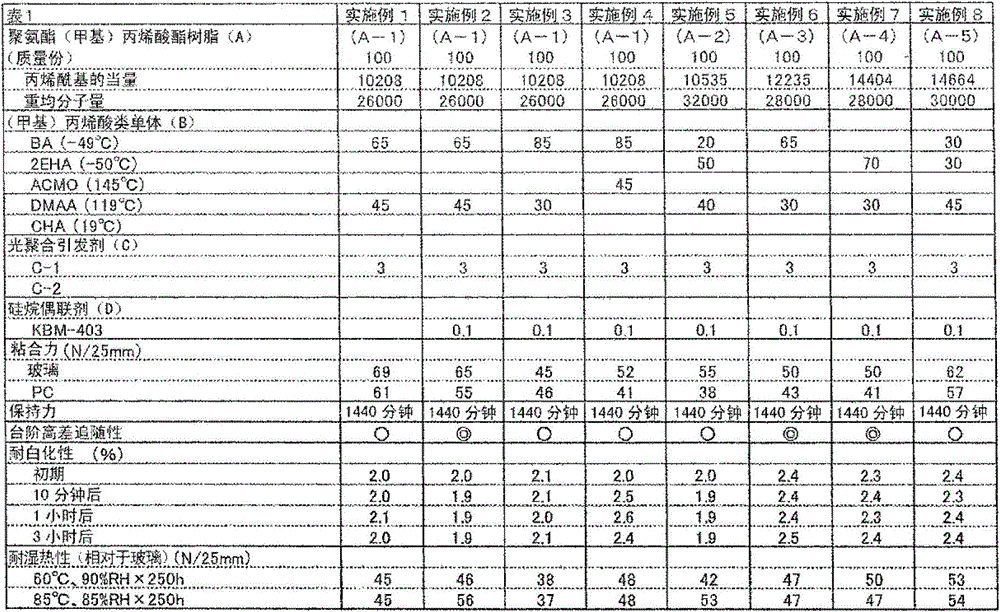

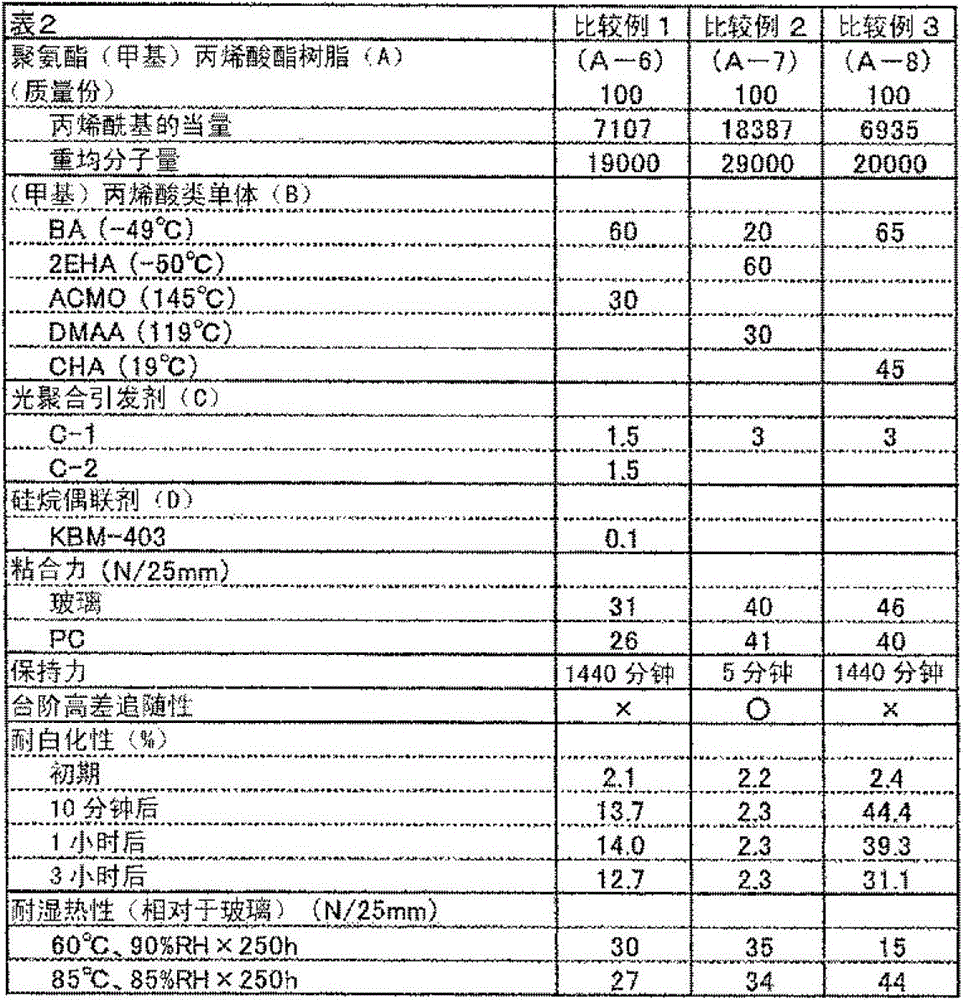

[0071] Hereinafter, although an Example demonstrates this invention more concretely, the scope of the present invention is not limited to these Examples.

[0072] In addition, in the present invention, "part" means "mass part", and "%" means "mass%" unless otherwise indicated.

Synthetic example 1

[0074]

[0075] Into a reaction vessel equipped with a stirrer, a reflux condenser, a nitrogen introduction tube, and a thermometer, 460 parts by mass of polytetramethylene glycol (number-average molecular weight: 1,000), 6.5 parts by mass of 2-hydroxyethyl acrylate, 2,6-ditertiary 2 parts by mass of butyl-cresol, and 0.3 parts by mass of p-methoxyphenol. After raising the temperature in the reaction container to 40°C, 105 parts by mass of isophorone diisocyanate was added. Then, 0.1 part by mass of dioctyltin dineodecanoate was added, and the temperature was raised to 80° C. over 1 hour. Then, it held at 80 degreeC for 12 hours, and after confirming that all the isocyanate groups disappeared, it cooled and obtained the urethane acrylate resin (A-1). The equivalent of the acryloyl group of the obtained urethane acrylate resin (A-1) was 10,208 (rounded off below the decimal point. The molecular weight of 2-hydroxyethyl acrylate was 116.1. The same applies below.), and the we...

Synthetic example 2

[0077]

[0078]653 parts by mass of polycarbonate polyol (Kuraray Polyol C-3090, manufactured by Kuraray Co., Ltd.) and 7.8 parts by mass of 2-hydroxyethyl acrylate were added to a reaction vessel equipped with a stirrer, a reflux condenser, a nitrogen introduction tube, and a thermometer. , 2,6-di-tert-butyl-cresol 2 parts by mass, p-methoxyphenol 0.3 parts by mass. After raising the temperature in the reaction container to 40°C, 47 parts by mass of isophorone diisocyanate was added. Then, 0.1 part by mass of dioctyltin dineodecanoate was added, and the temperature was raised to 80° C. over 1 hour. Then, it held at 80 degreeC for 12 hours, and after confirming that all the isocyanate groups disappeared, it cooled and obtained the urethane acrylate resin (A-2). The obtained urethane acrylate resin (A-2) had an acryloyl group equivalent of 10,535 and a weight average molecular weight of 32,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com