Special low-lead environment-friendly brass alloy ingot for gravity casting and manufacturing technique thereof

A gravity casting and brass alloy technology, applied in the metal field, can solve problems affecting the processing and performance of brass castings, and the uneven technical capabilities of plumbing manufacturers, and achieve reasonable ingredients and manufacturing processes, low cost, and excellent casting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the drawings:

[0028] A special low-lead environmentally friendly brass alloy ingot for gravity casting, which is characterized in that it contains copper Cu60.0-61.5wt%, lead Pb0.20wt%, aluminum Al0.6-0.7wt%, and tin Sn0.05-0.15wt% , Iron Fe0.05-0.15wt%, nickel Ni0.05-0.15wt%, boron B8-12PPM, bismuth Bi0.5-0.7wt%, zinc Zn balance and inevitable impurities 0.2wt%.

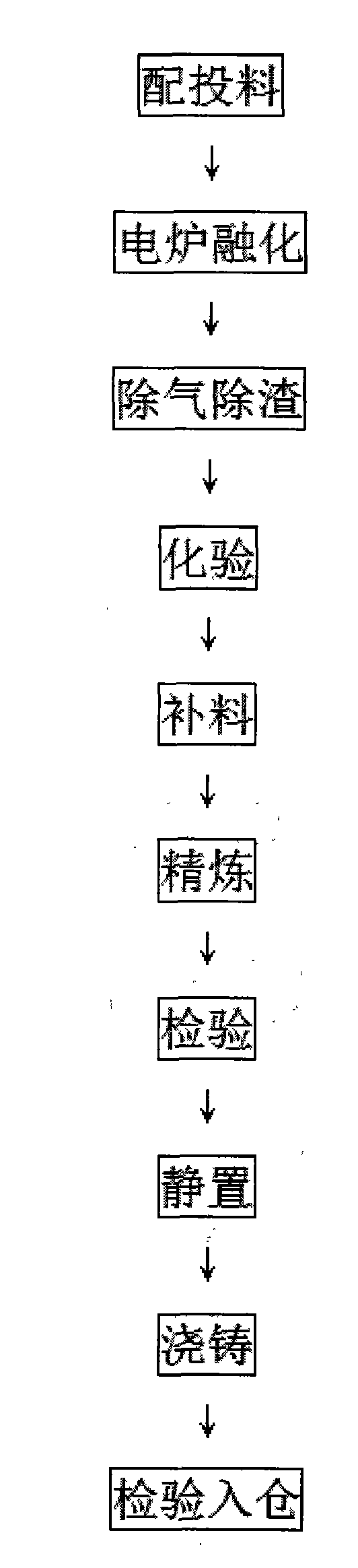

[0029] Such as figure 1 As shown, a manufacturing process of a special low-lead environmentally friendly brass alloy ingot for gravity casting includes the following steps:

[0030] a. With feeding materials:

[0031] Main ingredients: use 180KW power frequency electric furnace to melt copper; according to 1800kg of molten copper per furnace, the total weight of copper, zinc, and aluminum is controlled at 50%, specifically: red copper 29%-32% (optimally 30%), zinc 18%-21% (optimally 20%), aluminum 0.4%-0.5% (optimally 0.5%), the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap