Activated carbon flame-retardant adhesive

A flame-retardant adhesive and activated carbon technology, which is applied in textiles, papermaking, and fiber treatment, can solve the problems of fire-resistant adhesives against alkali, a large amount of toxic smoke, and poor flame-retardant performance, achieving good flame-retardant effects and saving consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

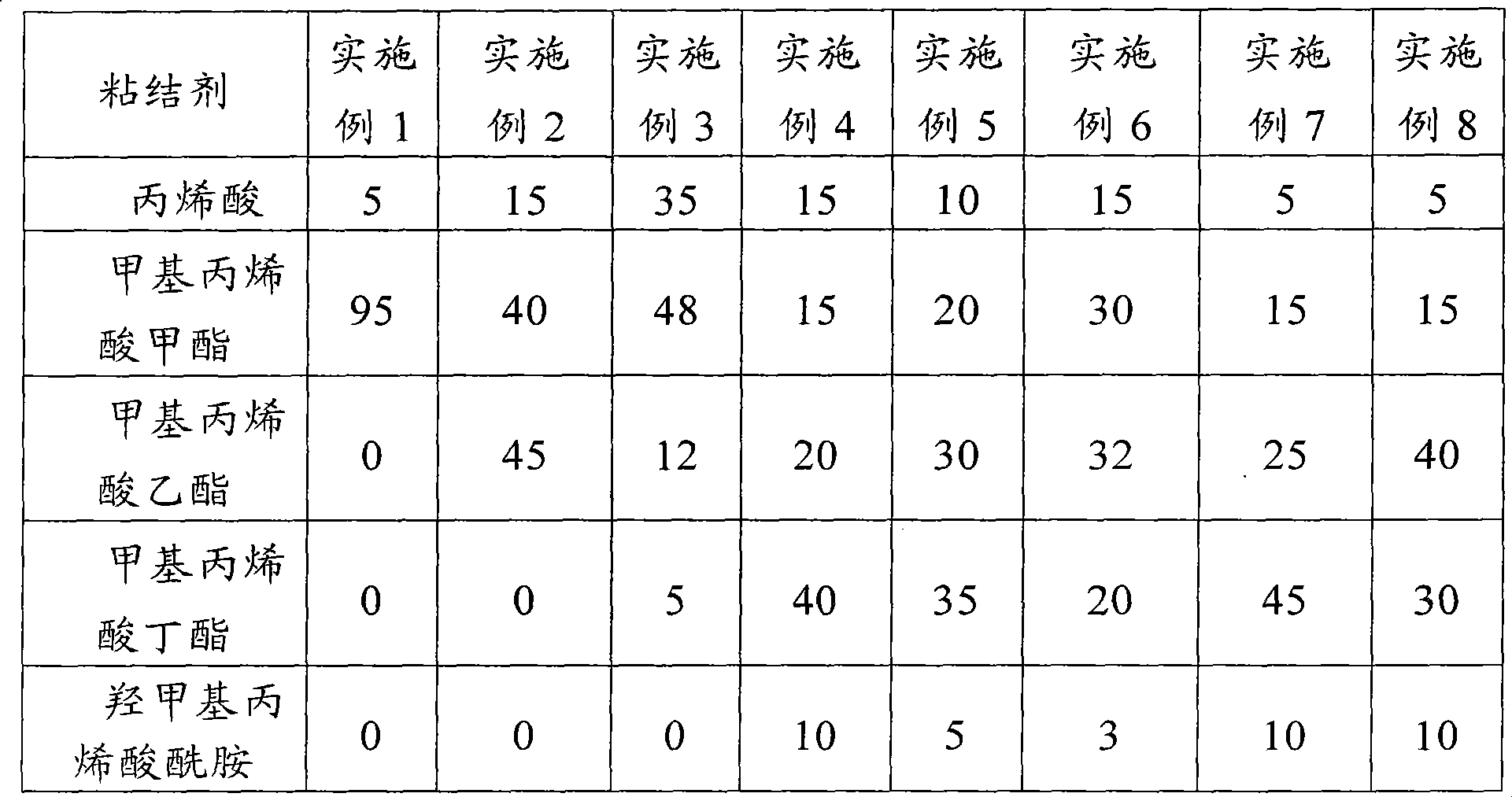

Embodiment 1

[0046] (a), based on the total weight of activated carbon flame retardant glue 100%, weigh 10% of expanded graphite and add 50% of the water with a temperature above 85°C, mix and stir evenly to prepare A solution, and continue to heat A solution to make it The temperature is maintained above 85°C;

[0047] (b), by weighing 100% of the weight of the binder, take by weighing 5% of acrylic acid, 95% of methyl methacrylate, and mix and stir evenly to prepare the binder; The binding agent is added in the A solution and stirred and mixed evenly to obtain the B solution;

[0048] (c), when the temperature of solution B drops to room temperature, add ammonia water to adjust the pH value of solution B to 6-7.

Embodiment 2

[0050] (a), according to the total weight of activated carbon flame-retardant glue 100%, weigh 20% of expanded graphite and add 45% of water with a temperature above 85°C, mix and stir evenly to prepare A solution, and continue to heat A solution to make it The temperature is maintained above 85°C;

[0051] (b), according to 100% of binder weight, take by weighing 15% of acrylic acid, 40% of methyl methacrylate, 45% of ethyl methacrylate, mix and stir evenly to prepare binder; In terms of 100% by weight, add 35% of the binder into the A solution and stir and mix evenly to prepare the B solution;

[0052] (c), when the temperature of solution B drops to room temperature, add ammonia water to adjust the pH value of solution B to 6-7.

Embodiment 3

[0054] (a), based on the total weight of activated carbon flame retardant glue 100%, weigh 50% of expanded graphite and add 20% of water with a temperature above 85°C, mix and stir evenly to prepare A solution, and continue to heat A solution to make it The temperature is maintained above 85°C;

[0055] (b), based on 100% of the weight of the binder, weigh 35% of acrylic acid, 48% of methyl methacrylate, 12% of ethyl methacrylate, and 5% of butyl methacrylate, and mix and stir evenly to obtain a bond agent; according to 100% of the total weight of the activated carbon flame-retardant adhesive, 30% of the binder is added to the A solution and stirred and mixed evenly to obtain the B solution;

[0056] (c), when the temperature of solution B drops to room temperature, add ammonia water to adjust the pH value of solution B to 6-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com