Foundation steel pile for solar photovoltaic power station

A solar photovoltaic and power station technology, applied in the field of solar photovoltaic power stations, can solve the problems of seasonal influence, the concrete foundation cannot be put into use immediately, and affect the construction progress, so as to achieve small seasonal and climate influence, high recycling rate, and reduce engineering costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

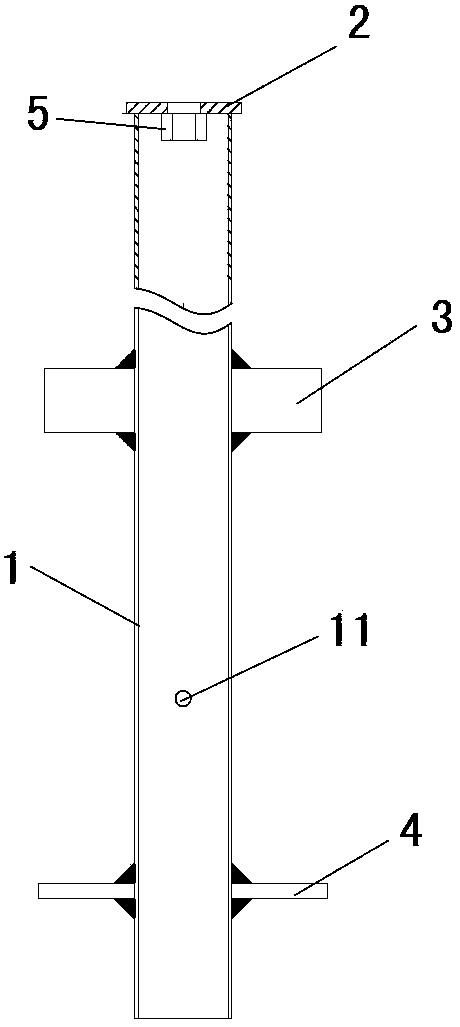

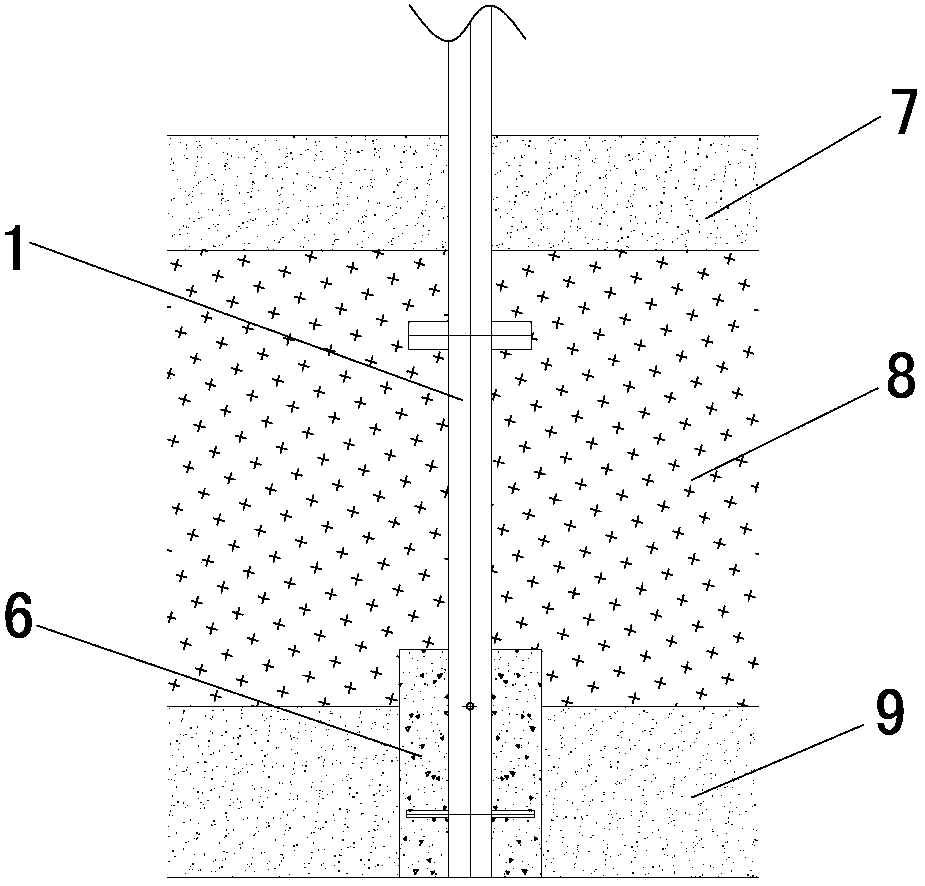

Embodiment 1

[0038] The invention relates to a foundation steel pile of a solar photovoltaic power station. Use a steel pipe 1 with an outer diameter of 76mm, a wall thickness of 3mm, and a length of 1600mm. The size of the flange 2 is 90*90*8. There is a hole with a diameter of 26mm in the center of the flange 2, and a hole is welded directly opposite the hole. M24 nut. The size of the radial positioning steel plate 3 is 70*50*4, and there are two pieces. The size of the axial positioning steel bar 4 is There are two rebars in total. The size of the radial positioning steel bar 11 is There are two rebars in total, and the distance from the bottom of the steel pipe 1 is 250mm. The center of the flange plate 2 is aligned with the center of the steel pipe 1 and is fully welded around one end of the steel pipe 1, with a weld seam of 5 mm and a weld leg of 45 degrees. Two radial positioning steel plates 3 are fully welded with the steel pipe 1 around, and the weld seam is 5 mm. Two axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com