Well drilling device and method for controlling bottom hole pressure by monitoring flow

A technology for bottom-hole pressure and flow monitoring, applied in wellbore/well components, earth-moving drilling, flushing wellbore, etc. The effect of convenient automatic control, reduction of control objects, and reduction of equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

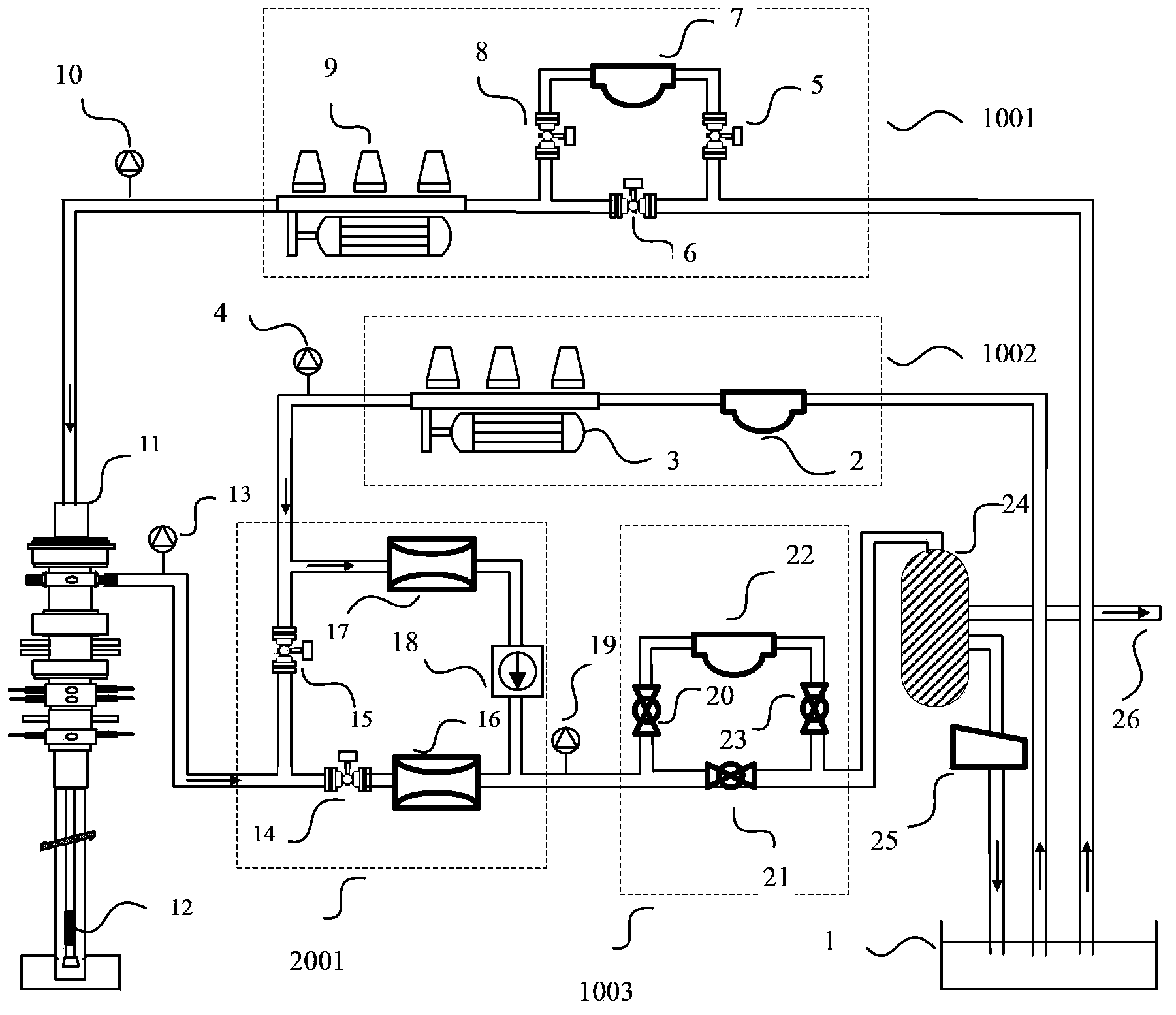

[0057] see figure 1 , a drilling equipment that uses flow monitoring to control bottomhole pressure, the equipment includes: mud pump inlet flow measurement system 1001, back pressure pump inlet flow measurement system 1002, drilling fluid return flow measurement system 1003, automatic throttle tube The sink system 2001, and the rotary control head 11, the liquid-gas separator 24, the vibrating screen 25, etc.; the dynamic sealing pressure of the rotary control head 11 is 14MPa, and the static sealing pressure is 35MPa; the back pressure pump 3 can be a 160 pump, and the rated working pressure is 35MPa , displacement: 12L / s; liquid-gas separator 24 liquid handling capacity: 200m 3 / h, gas handling capacity: 20000m 3 / h, working pressure: 1.5MPa.

[0058] Specifically, as a preference, the inlet of the mud pump inlet flow measurement system 1001 is connected to the mud tank 1 by a pipeline, and the outlet of the mud pump inlet flow measurement system 1001 is connected to the ...

Embodiment 2

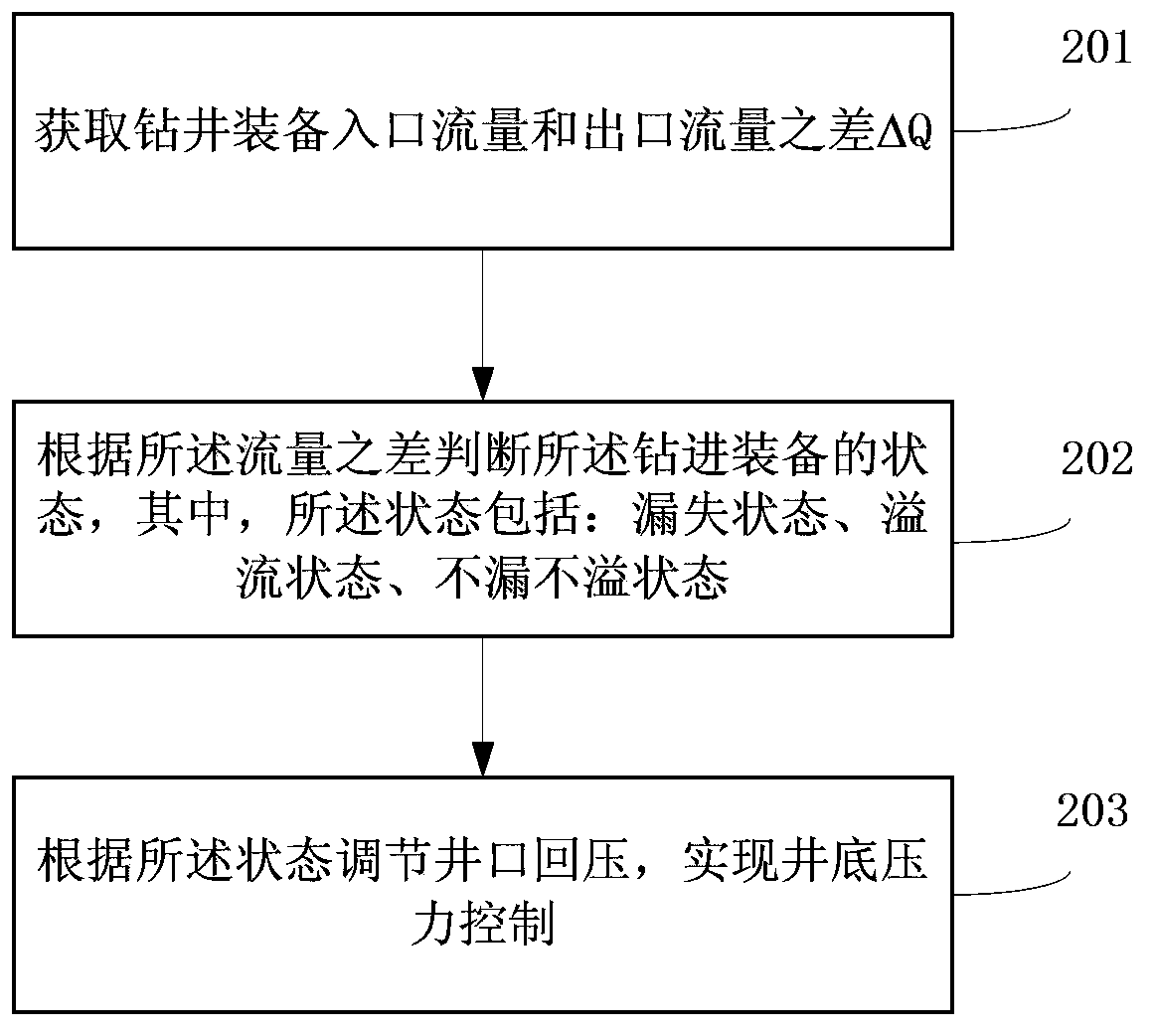

[0065] The present invention also provides a method for controlling the bottomhole pressure by using the flow monitoring of the drilling equipment described in Embodiment 1. During drilling, the drilling conditions are divided into three basic conditions: normal drilling, tripping, and single root connection , Tripping generally refers to the replacement of drilling tools. Lifting the drilling tools out of the ground from the ground is called "tripping". Bottom, called "drilling down", single connection generally means that during the drilling process, when the uppermost part of the kelly is about to reach the bushing and cannot continue drilling, the kelly needs to be lifted out, and then a kelly should be connected above the lower part of the kelly. In order to continue drilling down the drill pipe, the process of connecting only one drill pipe is called single connection.

[0066] Through analysis under different working conditions, it is judged that the equipment is in the...

Embodiment 3

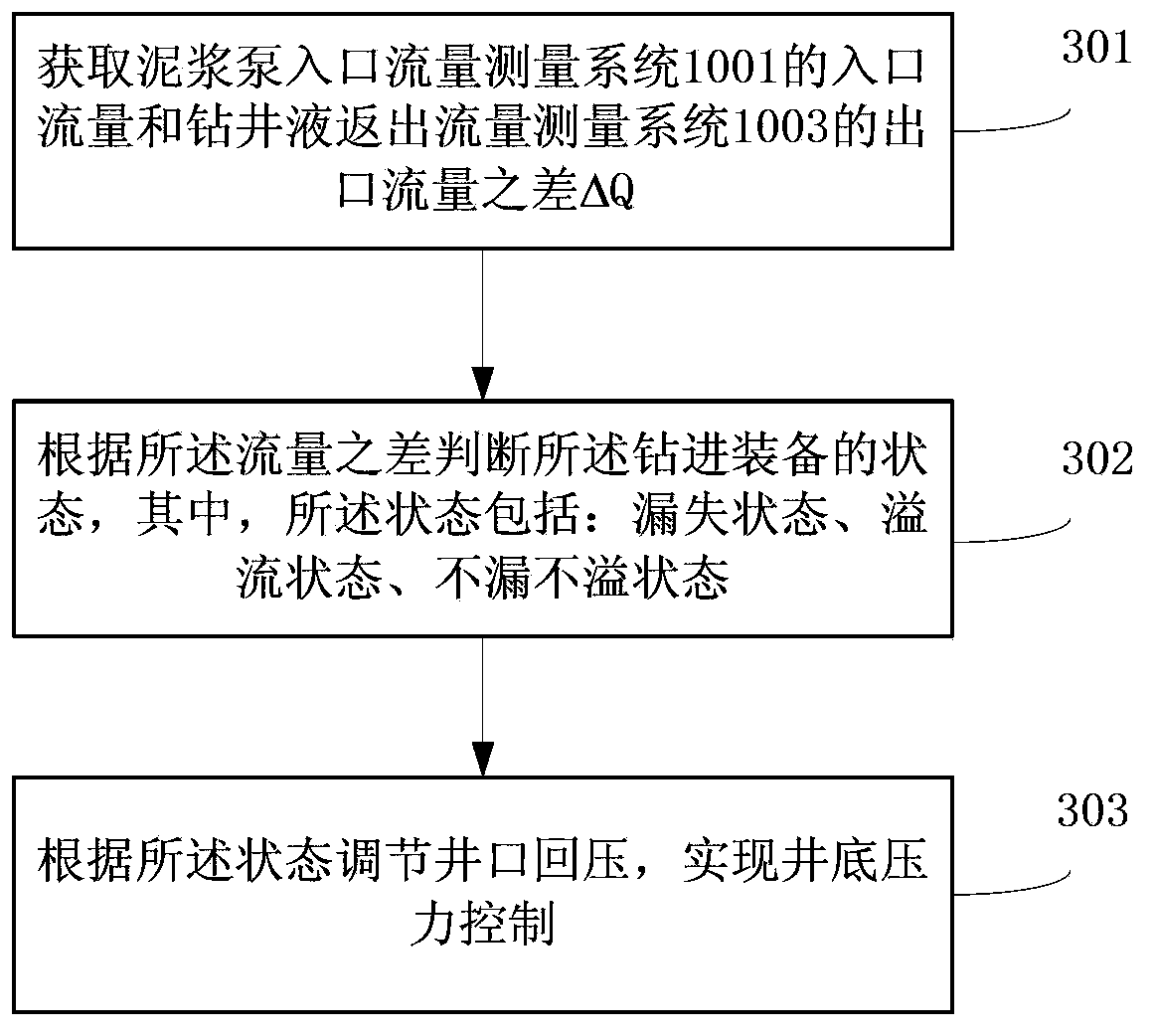

[0073] This embodiment provides a method for controlling the bottomhole pressure by using the flow monitoring of the drilling equipment described in the first embodiment. Combining with the content of the first embodiment above, this embodiment takes the normal drilling working condition as an example for illustration. Under normal drilling conditions, the drilling fluid is sucked from the mud tank 1, passed through the first manual plate valve 5, the second mass flow meter 7 and the third manual plate valve 8, and then pumped into the drill string through the mud pump 9, and the drilling fluid is pumped into the drill string by the drill pipe From the water hole to the bottom of the well, return to the ground from the wellbore annulus, blocked by the rotary control head 11, reversed and enter the automatic throttle manifold system 2001, pass through the first air control plate valve 14 and then pass through the first hydraulic throttle valve Throttle 16, enter the drilling flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com