Fiber-reinforced flame-retardant and antistatic thin-wall steel-plastic composite pipe and its forming process

A flame-retardant, antistatic, steel-plastic composite pipe technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problem that the overall indicators of compression resistance, tensile resistance and burst resistance are far apart, and steel-plastic composite pipes The thickening of the pipe wall and the increase in weight can reduce the difficulty of installation and labor intensity, the combination of corrosion-resistant interface and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

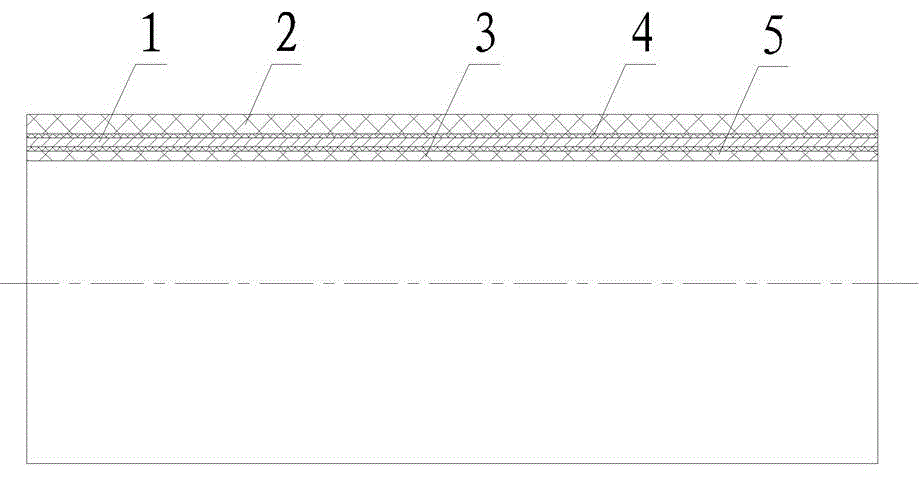

[0014] The invention relates to a fiber-reinforced flame-retardant and antistatic thin-walled steel-plastic composite pipe and its forming process. The outer transition interface layer 4 is formed by coating or winding process, and the inner transition interface layer 5 is formed on the inner wall of the thin-walled metal pipe 1 by means of a spraying process, and the fiber resin reinforced layer 2 is formed on the outer surface of the outer transition interface layer 4 by means of a winding process, and the inner transition The inner surface of interface layer 5 forms wear-resistant antistatic coating 3 by means of spraying process, see figure 1 .

[0015] In the present invention, in order to enhance the bonding force between the thin-walled metal pipe 1 and the fiber resin reinforced layer 2 and the wear-resistant and antistatic coating 3, between the thin-walled metal pipe 1 and the fiber resin reinforced layer 2, and between the thin-walled metal pipe 1 and the fiber resi...

Embodiment 2~4

[0025] As the second embodiment of the present invention, the silane coupling agent and the titanate coupling agent are respectively configured as the external interface penetrating agent and the internal interface penetrating agent according to the following weight percentages:

[0026] Coupling agent 15-20%,

[0027] Resin 8-15%

[0028] Ethanol 55-68%

[0029] water balance,

[0030] Spray the outer interface penetrating agent and the inner interface penetrating agent on the outer wall and inner wall of the thin-walled metal pipe 1 respectively for 3-5 times to form an outer interface penetrating layer and an inner interface penetrating layer; process the outer transition interface layer 4 and the inner interface layer after drying. Transition interface layer 5.

[0031] Specifically, see Table 1 and Table 2 for the components and weight percentages of the external interface penetrating agent and the internal interface penetrating agent in each embodiment.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com