An energy-saving heat pump dehumidification drying room and its control method

A control method and an energy-saving technology, applied in the field of baking rooms, can solve the problems of energy waste, large energy consumption, and unrecyclable heat energy, and achieve the effects of reducing energy consumption, avoiding excessive moisture removal, and reducing temperature loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

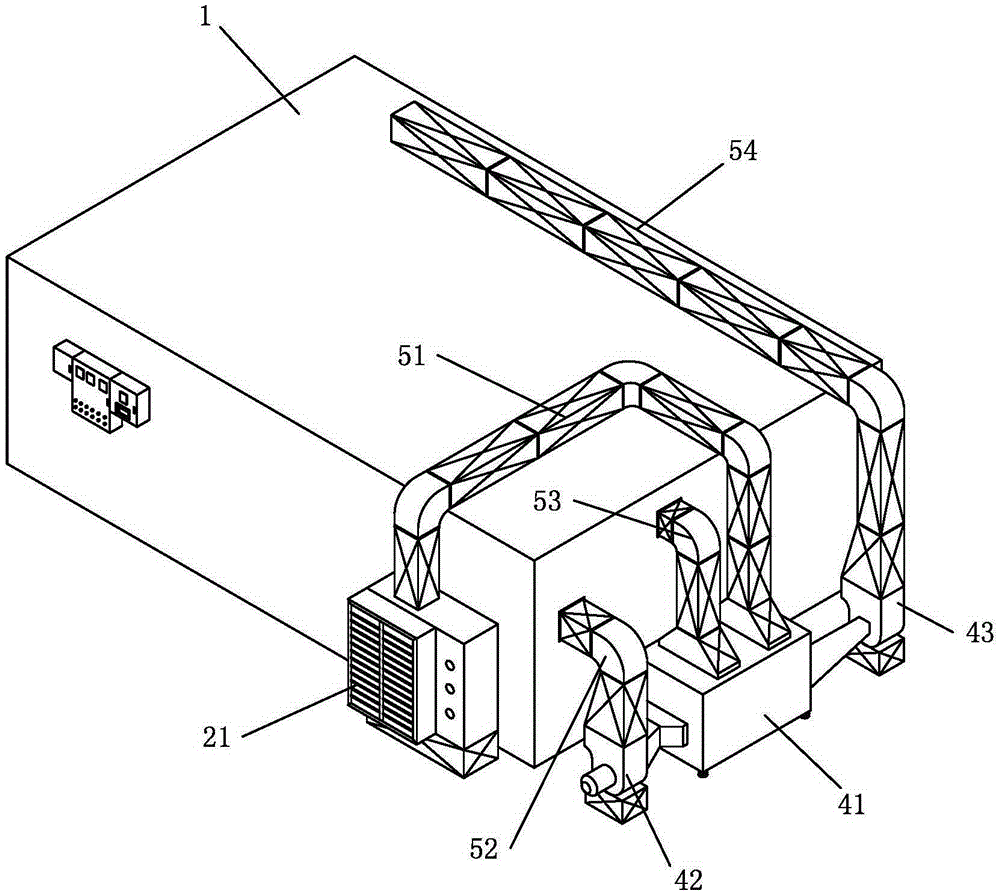

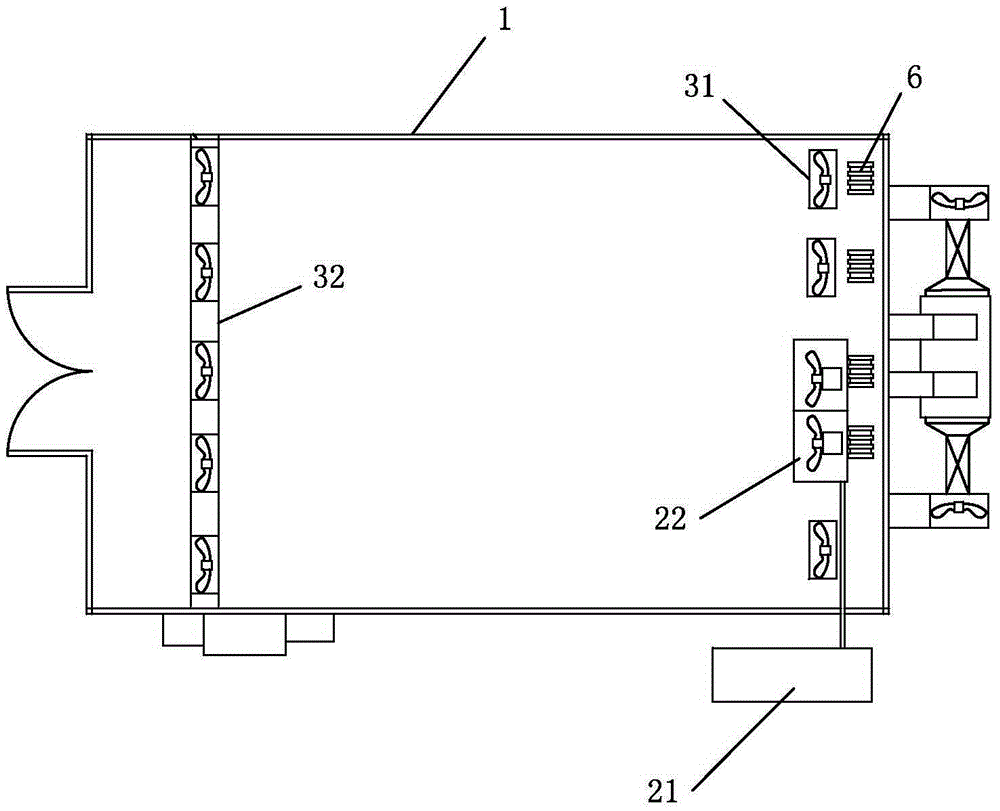

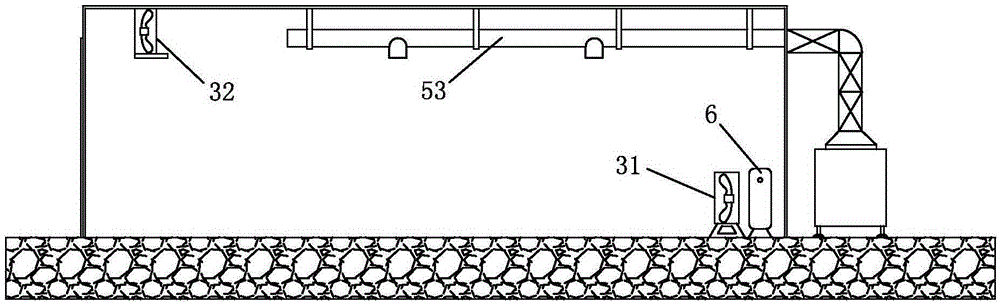

[0044] refer to Figure 1 to Figure 4, an energy-saving heat pump dehumidification drying room of the present invention includes a room body 1, a heat pump assembly, a circulating fan assembly and a dehumidification assembly. The heat pump assembly includes a heat pump main machine 21 arranged outside the house body 1 and a heat pump auxiliary machine 22 arranged inside the house body 1. The heat pump main machine 21 includes an evaporator, a throttling device, and a compressor, and the heat pump auxiliary machine 22 includes a condenser. The evaporator, compressor, condenser, and throttling device are sequentially connected through pipelines to form a circulation system; The heat exchanger 41 of non-direct contact convective heat exchange, the inside of the heat exchanger 41 is provided with a fresh air channel and a dehumidification channel that are not connected to each other, and the entrance of the fresh air channel is connected with a cold air pipeline 51 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com