Novel resistance furnace

A resistance furnace, a new type of technology, applied in the direction of electric furnace heating, furnace, furnace type, etc., can solve the problems of easy heat loss, short service life of resistance wires, troublesome manufacturing and maintenance, etc., to achieve good sealing effect, prolong service life, and manufacture maintenance. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

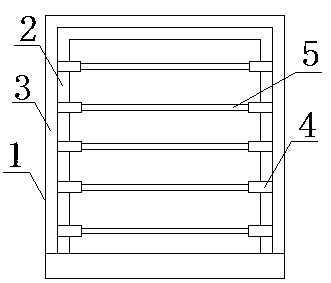

[0010] Such as figure 1 It is a schematic diagram of the structure of the present invention, a new type of resistance furnace, including a furnace body 1, a furnace wall 2, a refractory fiber layer 3, a wire slot 4 and a resistance wire 5, and a refractory fiber layer is arranged between the furnace body 1 and the furnace wall 2 3. The furnace wall 2 is provided with a wire trough 4, the wire trough 4 is provided with a resistance wire 5, and the outside of the wire trough 4 is covered with a layer of infrared ceramic coating.

[0011] When in use, a refractory fiber layer 3 is provided between the furnace body 1 and the furnace wall 2, and the furnace wall 2 is provided with a wire resting groove 4. Layer infrared ceramic coating. This new type of resistance furnace has a simple, compact and reasonable structure, convenient and quick assembly, reliable connection, high efficiency and energy saving, and good sealing effect, which can prevent a large amount of heat loss, reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com