Method for measuring back vertex power of lens

A technology of back vertex power and measurement method, which is applied in the direction of testing optical performance, etc., can solve the problems of unguaranteed measurement accuracy, huge instrument measuring device, and large space occupation, so as to achieve small instrument occupation space, small instrument measuring device, and measurement Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

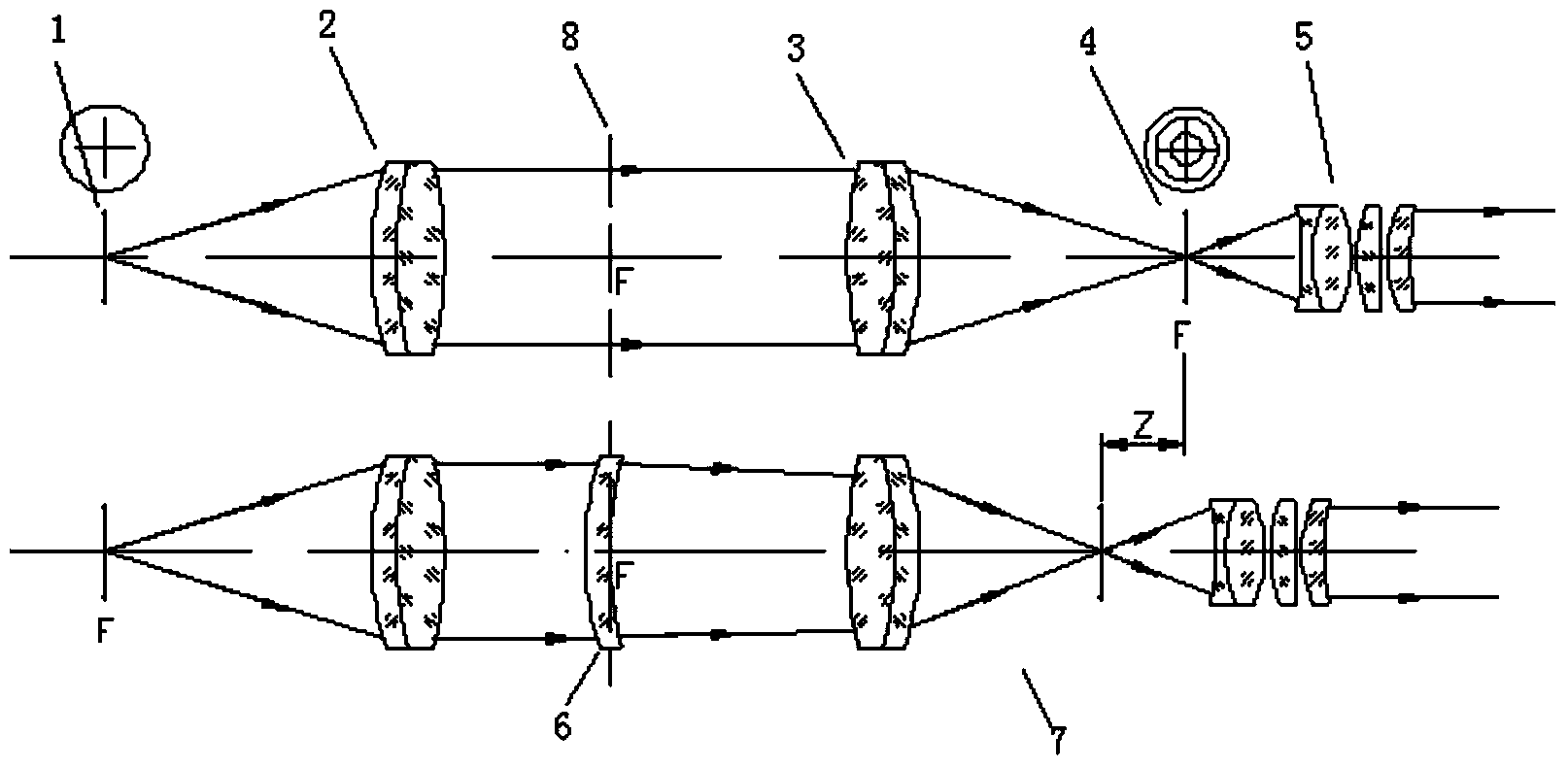

[0029] A kind of measuring method of lens back vertex of the present invention, such as image 3 , including a light source, a target reticle 1, a collimating objective lens 2, and a telescope 7, and also includes the following steps:

[0030] 1) Use the target reticle 1 with the collimating objective lens 2 to produce an infinite target. When the lens 6 under test is not placed in the optical path, the target reticle 1 is located on the focal plane of the collimating objective lens 2, and can be viewed from the telephoto A clear marked image is obtained in the telescopic system composed of the objective lens 3 and the eyepiece 5;

[0031] 2) Place the lens under test 6 between the collimating objective lens 2 and the telescopic objective lens 3;

[0032] 3) Adjust the image square reticle 4, then the image square reticle 4 needs to move a certain distance z along the optical axis in order to obtain a clear image of the target differentiation plate in the telephoto system aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com