Method for assembling display device

A technology of a display device and an assembly method, which is applied to printed circuits, instruments, electrical components, etc., can solve problems such as gold finger breakage, and achieve the effect of avoiding breakage and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

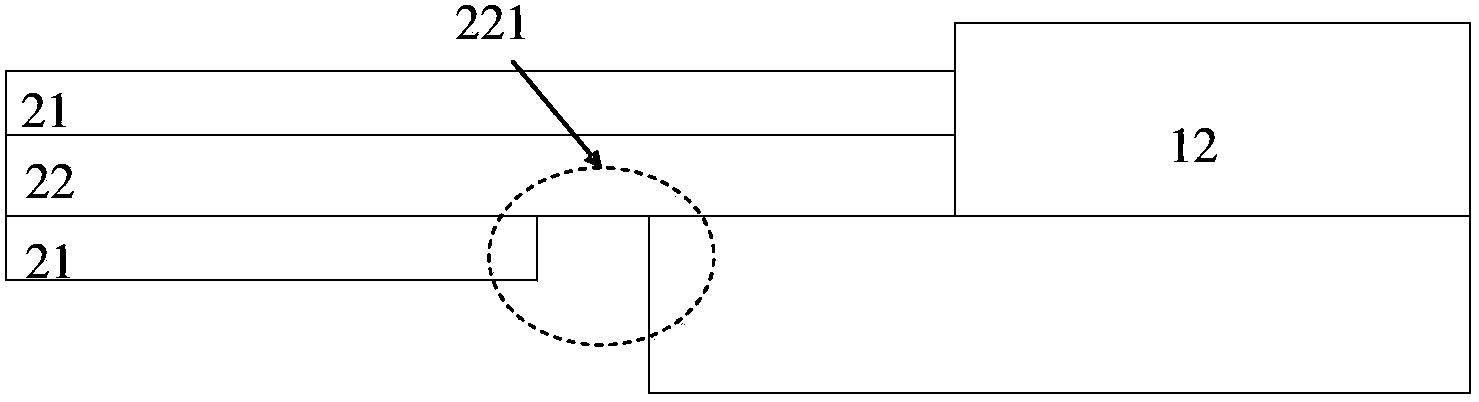

[0030] The basic idea of the present invention is: in the assembly method of the display device, the exposed conductive glue on the FPC gold finger is cured to form a protective film, which can prevent the gold finger from breaking and ensure sufficient connection between the FPC and the display panel.

[0031] Wherein, the conductive adhesive may be anisotropic conductive adhesive film (ACF).

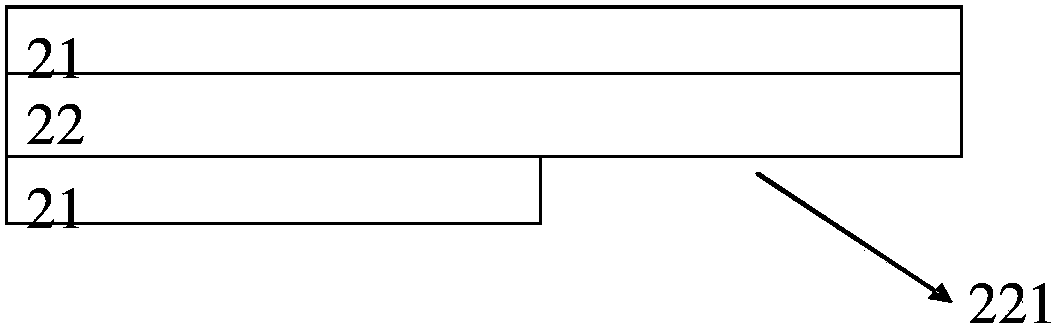

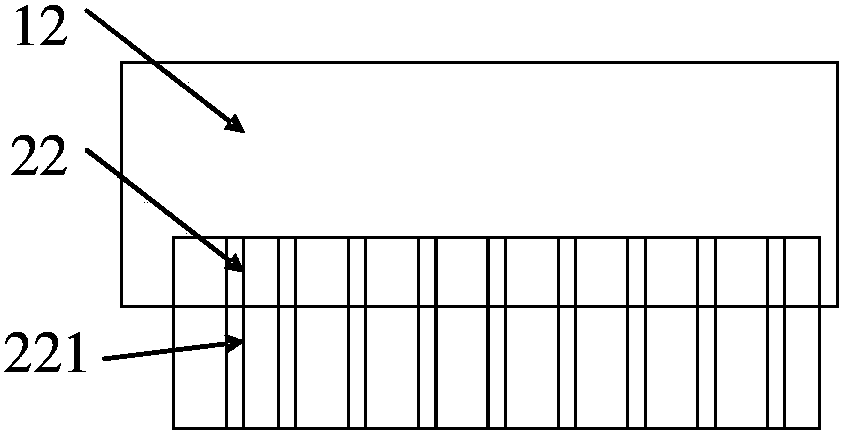

[0032] FPC structure of the present invention such as Figure 4 As shown, the FPC includes a base material 21, a gold finger 22 and a conductive glue 23, wherein the upper surface of the gold finger 22 is provided with the base material 21, a part of the lower surface is provided with the base material 21, and the other part is the gold finger Conductive glue 23 is coated on the part exposed in the air. In this way, after the FPC is bound to the LCD screen, no gold finger will be exposed in the air.

[0033] In particular, the conductive adhesive 23 may be ACF with anisotropic cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com