Optical proximity effect correction method

A technology of optical proximity effect and lithography process, applied in optics, original parts for opto-mechanical processing, instruments, etc., can solve the problem of lithography line width drift, etc., to avoid waste and avoid lithography line width drift. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

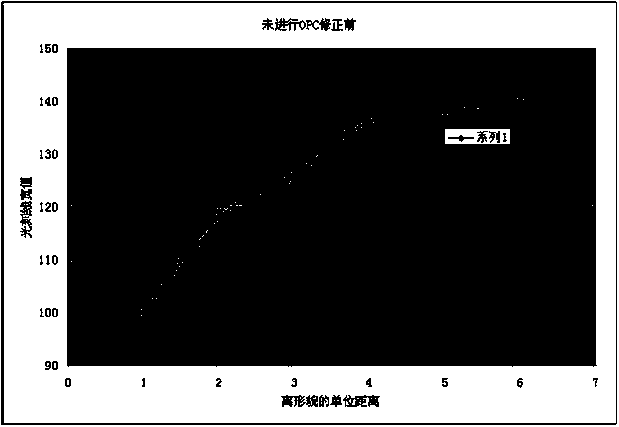

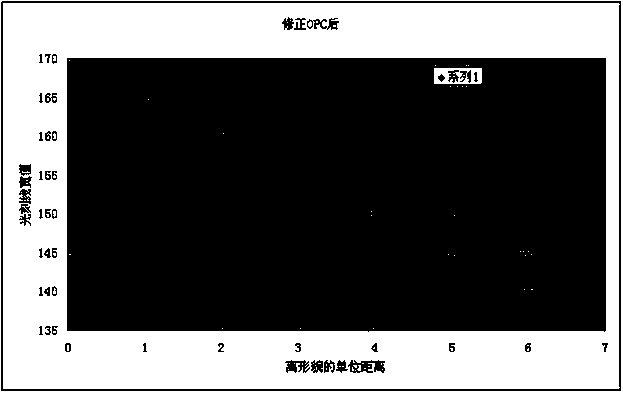

[0018] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

[0019] The flow process of OPC correction method of the present invention is as follows:

[0020] Step 1. Make two test photoresist plates, wherein, the first photoresist plate is designed according to the topography of the front layer, and is used to place the front layer graphics, that is, the graphics of the front layer that produces morphology or film layer changes; the second photolithography plate The engraving plate is used to place the test pattern of the rear OPC around the topographical pattern according to certain rules.

[0021] The method of placing the OPC test pattern is: repeat the placement according to the distance from the pattern that generates the shape. Place the OPC test pattern in the Y direction (that is, the direction perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com