Continuous multi-section radial reactor

A technology of reactors and reaction sections, applied in the field of continuous multi-section radial reactors, which can solve problems such as easy blockage, high energy consumption, and difficult catalyst transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

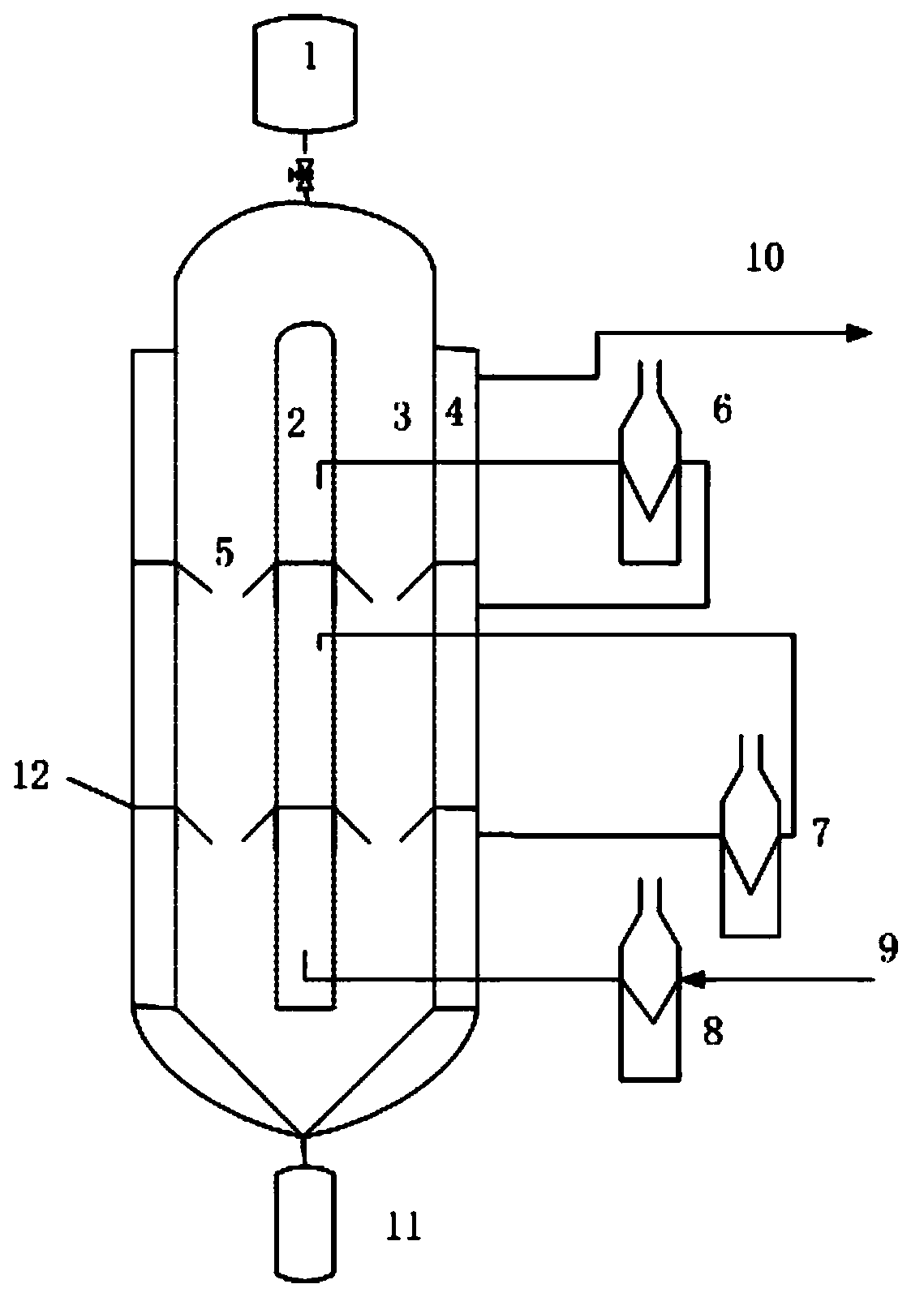

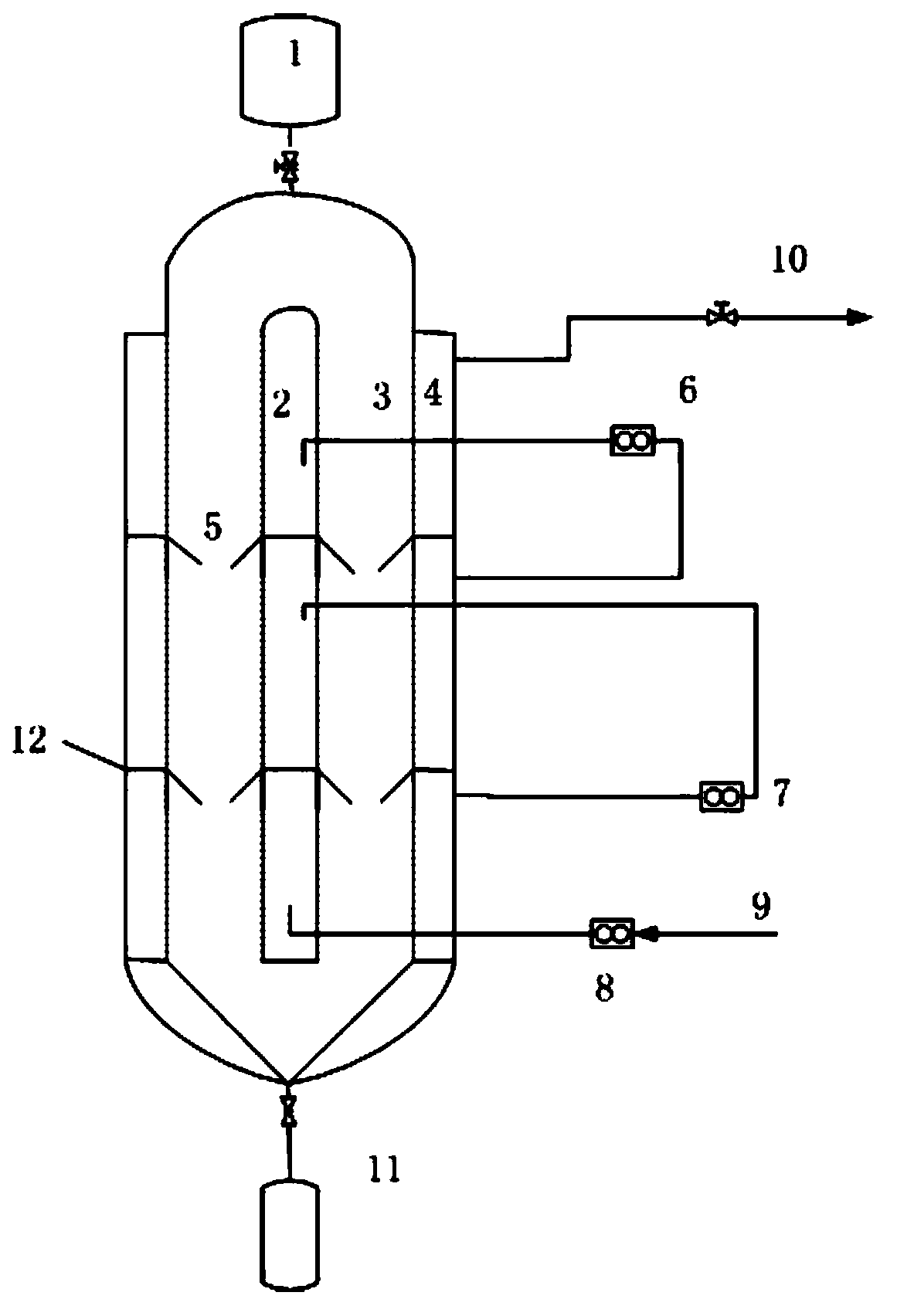

[0012] Simulations were carried out in the laboratory, as shown in the attached figure 2 As shown, in a transparent reactor model, the diameter of the outer cylinder (4) of the reactor is 20cm, the diameter of the inner cylinder (2) is 5cm, and the diameter of the middle cylinder (3) is 15cm. The inner cylinder and the middle cylinder are made of screen mesh, and the inner cylinder Alumina balls with a diameter of 1-2mm are installed between the reactor and the middle cylinder to replace the catalyst until the top of the reactor is equipped with alumina balls; the inner cylinder and the outer cylinder of the reactor are divided into three sections, each section is 70cm high, and the bottom The first paragraph, followed by the second paragraph, and the third paragraph. Compressed air (replacing the reaction material) first enters the first section of the inner cylinder, connects from the first section of the outer cylinder to the second section of the inner cylinder, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com