Mechanism powder forming machine and quantitative oil supply system

An oil supply system, mechanical technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of increasing production costs, breaking, and scrapping products, and achieves the effects of convenient production, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

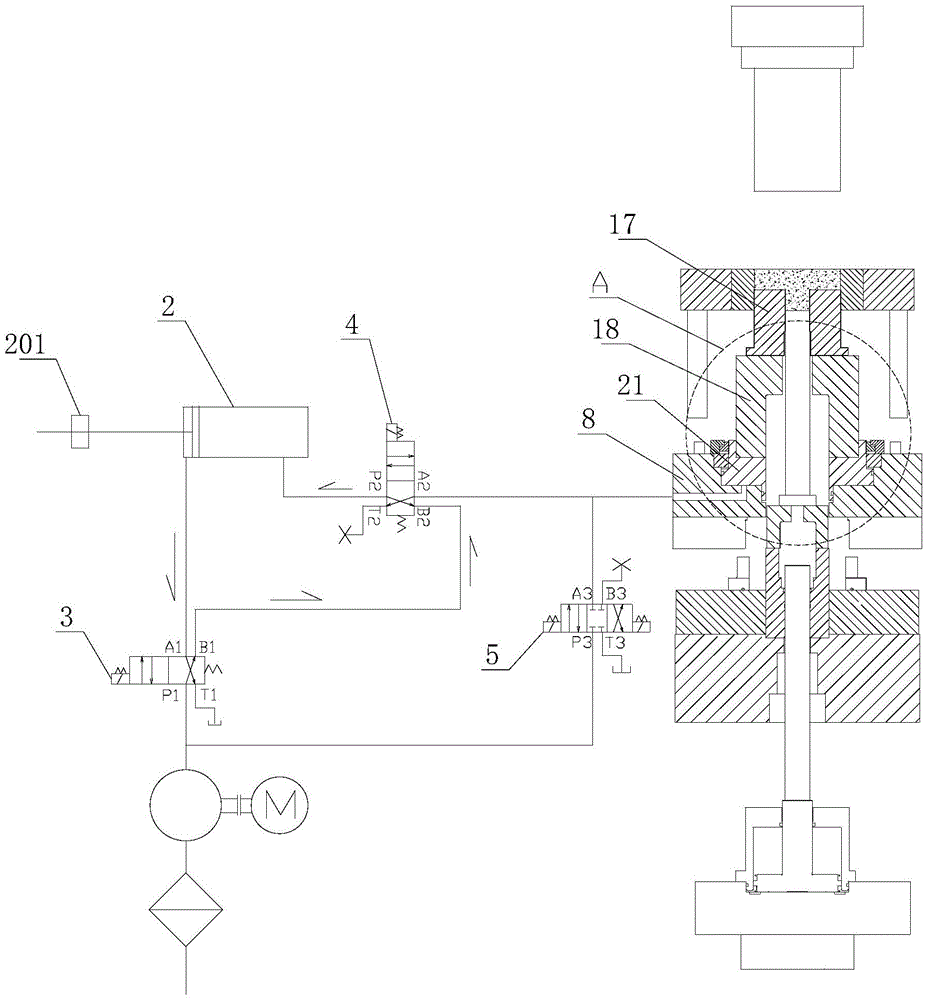

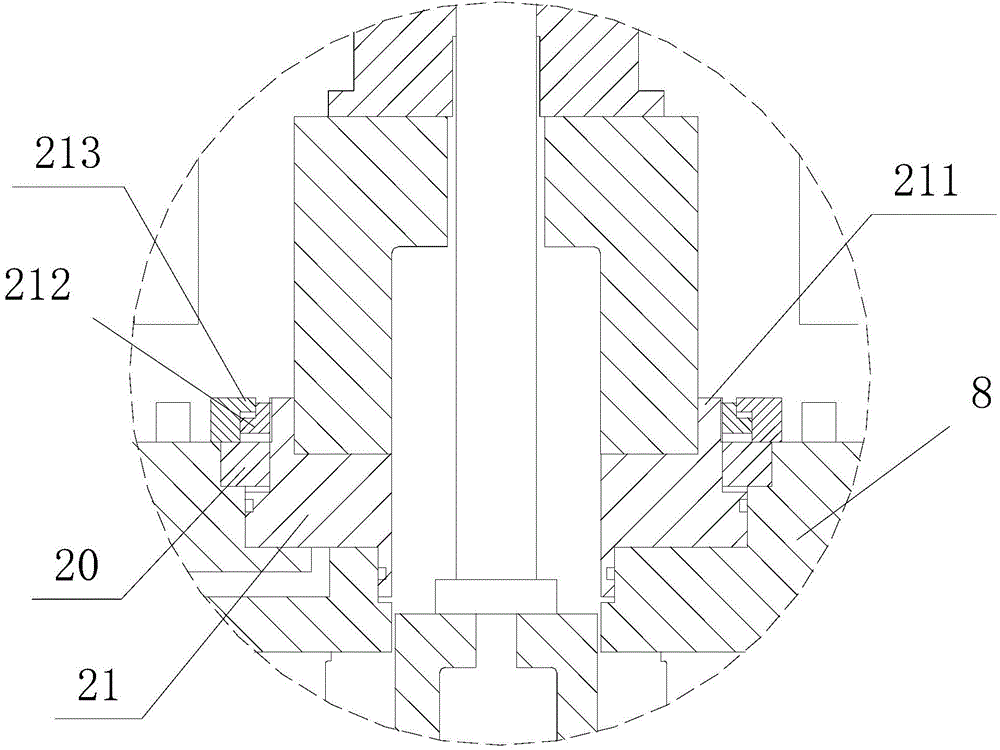

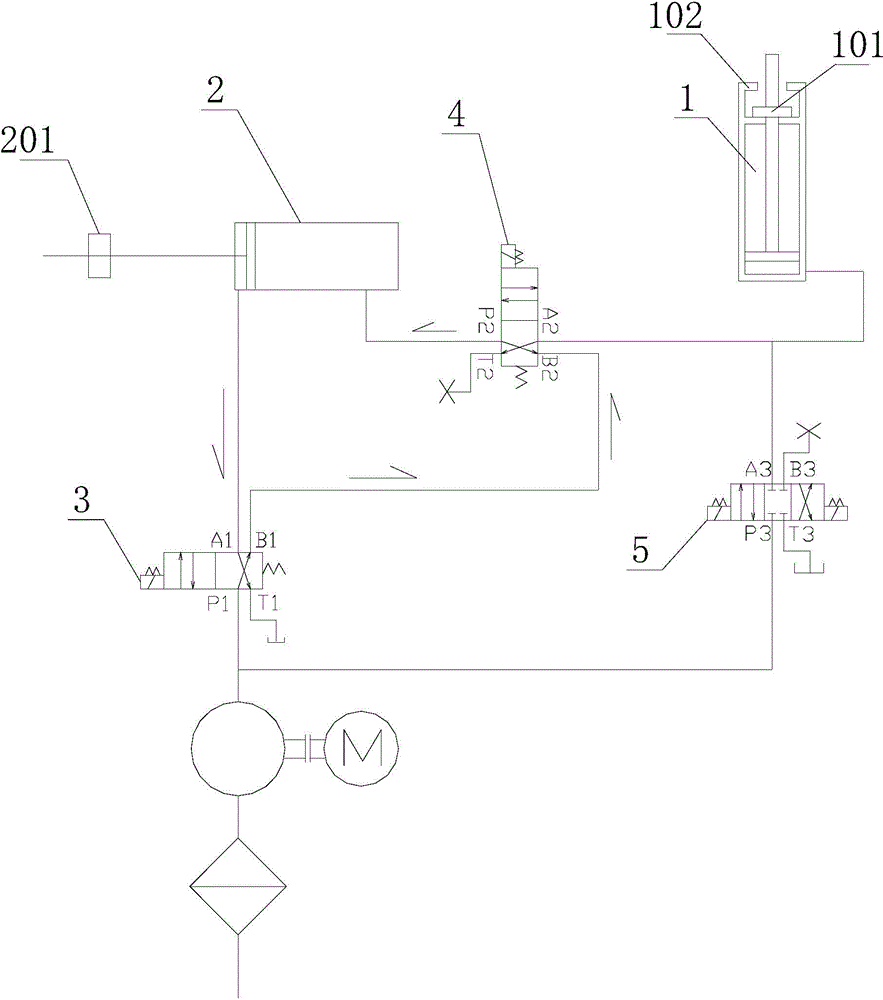

[0018] refer to Figure 3 ~ Figure 6 , in order to solve the above technical problems, the present invention provides a quantitative oil supply system, including an oil pump connected to the fuel tank, and also includes a ejection cylinder 1, a quantitative oil cylinder 2, a first electromagnetic reversing valve 3, a second electromagnetic reversing valve 4 And the third electromagnetic reversing valve 5, the piston rod of the quantitative oil cylinder 2 is provided with an adjustment nut 201 for adjusting the stroke of the piston, the piston rod of the ejection cylinder 1 is provided with a stroke adjustment nut 101, and the end of the ejection cylinder 1 is provided with a There is a limit block 102 for limiting the stroke adjustment nut, and the oil port of the rodless cavity of the ejection cylinder 1 is branched into two branches, the first branch is connected to the quantitative cylinder 2 after passing through the second electromagnetic reversing valve 4 The oil port in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com