Sodium cyanide storage tank

A technology for sodium cyanide and storage tanks, which is applied in the direction of tank cars, transport passenger cars, railway car body parts, etc., which can solve the problems of pressure vessel category promotion, waste of space, and high cost, and achieve reduction of storage costs, simplification of manufacturing processes, and equipment structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below according to accompanying drawing:

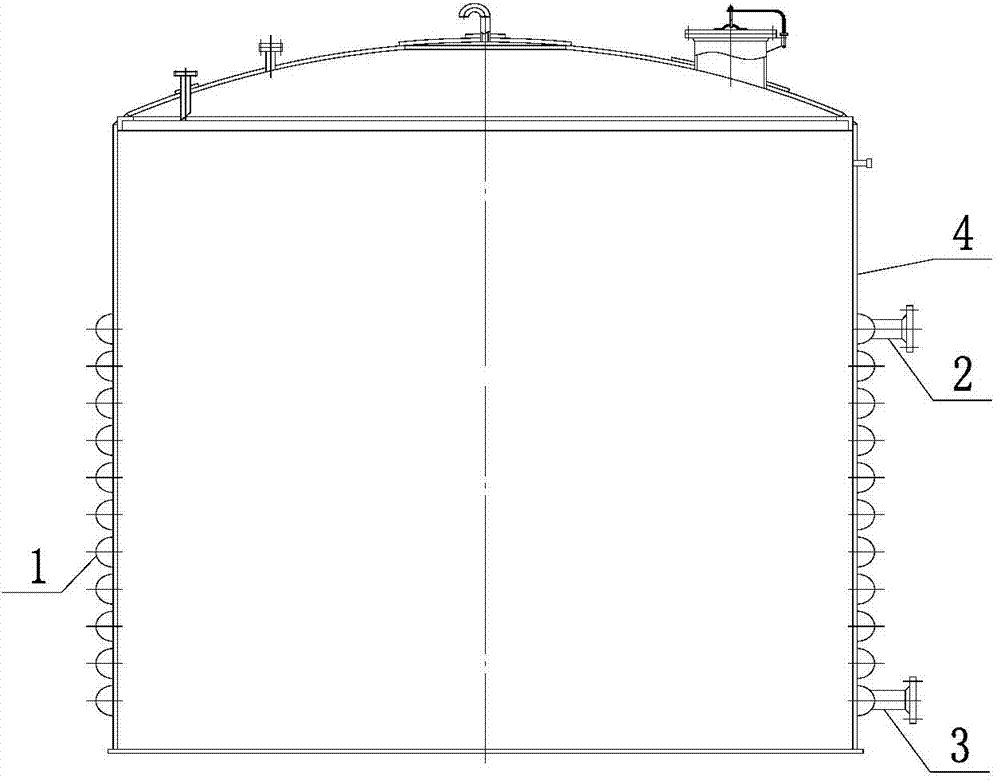

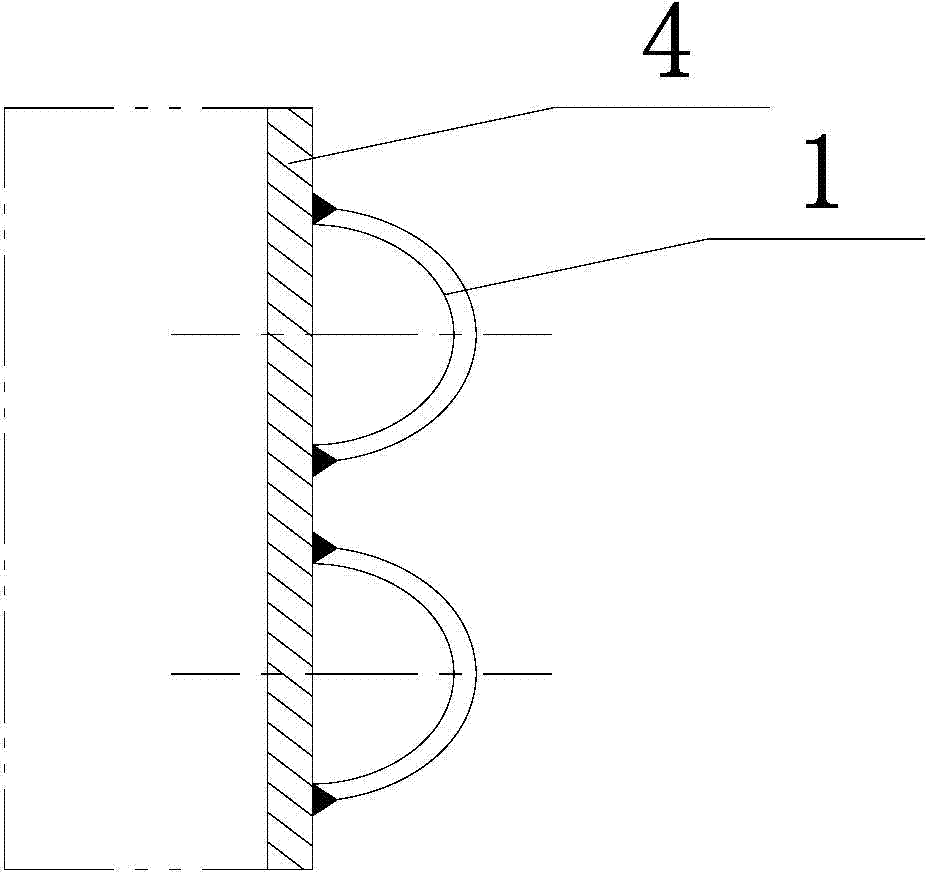

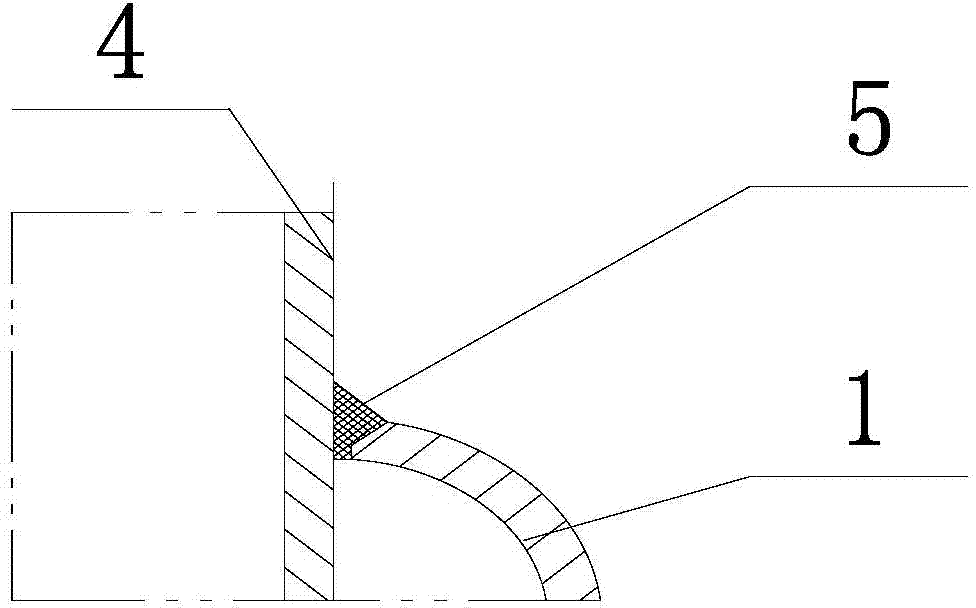

[0032] as attached figure 1 As shown, the present invention intends to add a heat tracing half-pipe jacket 1 on the outer wall of the conventional storage tank, specifically welding the half-pipe jacket on the equipment body 4 within the range of the equipment charging coefficient, and at the uppermost and outermost ends of the half-pipe jacket The lower end is respectively welded to the upper port 2 of the jacket and the lower port 3 of the jacket; if attached Figure 2a The shown half-pipes are cut from stainless steel pipes with a diameter of 50 mm to 125 mm, and a certain amount of gap is left between adjacent half-pipes 1 to facilitate welding operations during the processing of equipment half-pipe jackets. as attached Figure 3a As shown, the uppermost and lowermost half-pipe jacket ends 7 of the outer wall half-pipe jacket of the equipment are respectively welde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com