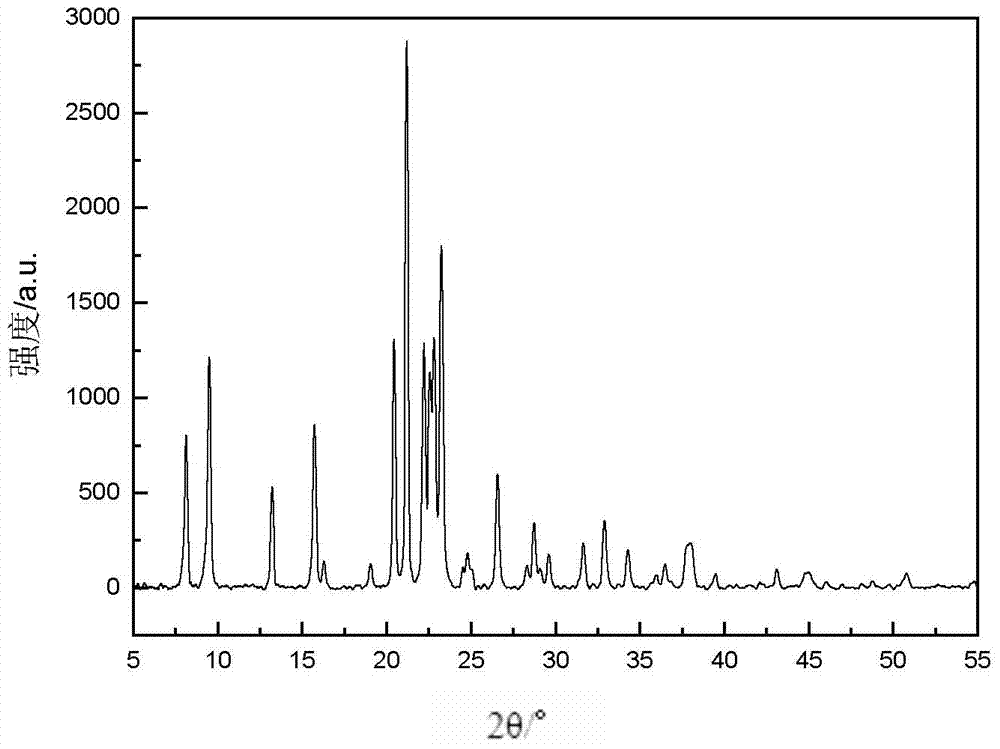

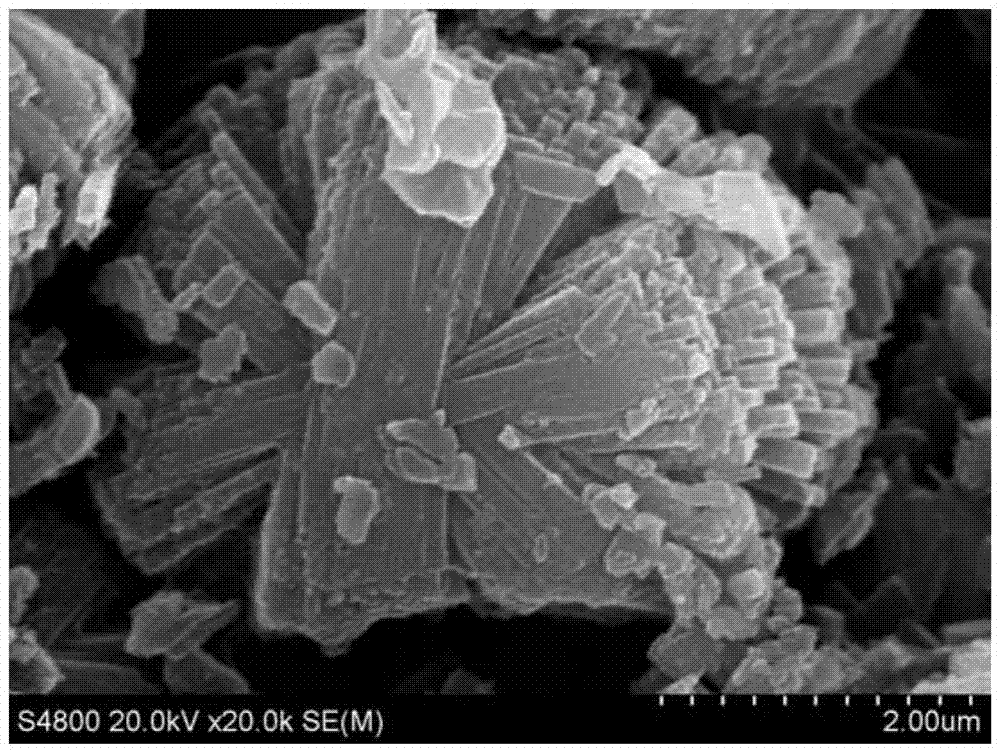

Method for preparing SAPO-11 molecular sieve

A SAPO-11, molecular sieve technology, applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problem of easy generation of other silicoaluminophosphate molecular sieves, such as miscellaneous crystals, and achieve strong acidity controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of a kind of SAPO-11 molecular sieve of present embodiment, carry out according to the following steps:

[0018] 1. Preparation of the initial gel: Add phosphoric acid with a mass fraction of 85%, pseudoboehmite with a mass fraction of 69%, di-n-butylamine with a mass fraction of 95%, and silica sol with a mass fraction of 27%. into deionized water and stirred at a speed of 800r / min to 2000r / min for 1h to 5h to obtain an initial gel; the mass fraction is 85% of phosphoric acid and 69% of pseudo-boehmite Mass ratio is 1:(0.5~0.8); Described mass fraction is that the mass ratio of phosphoric acid of 85% and mass fraction is 95% di-n-butylamine is 1:(0.6~1.0); Described mass fraction is The mass ratio of 85% phosphoric acid to 27% silica sol is 1:(0.05~1.0); the mass ratio of 85% phosphoric acid to deionized water is 1:(3.9~4.7) ;

[0019] 2. Crystallization and post-treatment: Place the initial gel prepared in step 1 in a ...

specific Embodiment approach 2

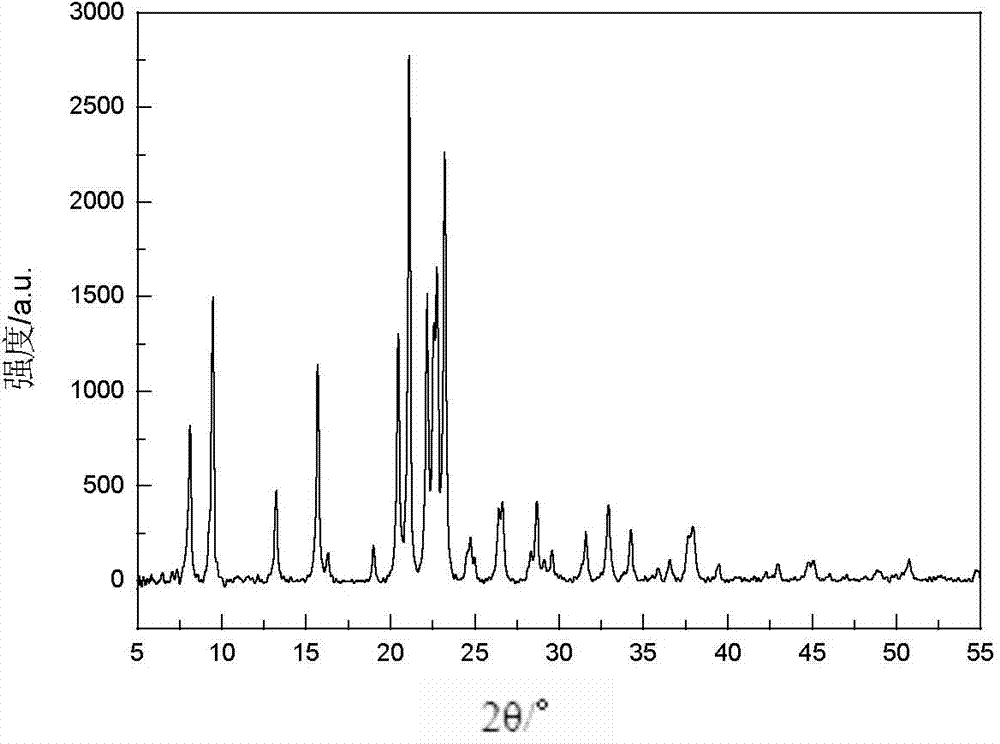

[0022] Specific embodiment two: what this embodiment is different from specific embodiment one is: the mass fraction described in step one is that the mass fraction of the phosphoric acid of 85% and mass fraction is the mass ratio of the pseudo-boehmite of 69% is 1:(0.6 ~0.7); The mass fraction described in step one is that the mass ratio of the phosphoric acid of 85% and the mass fraction of 95% di-n-butylamine is 1:(0.7~0.9); The mass fraction described in step one is 85% % phosphoric acid and mass fraction are 1:(0.07~0.9) for the mass ratio of silica sol of 27%; The mass ratio described in step one is 85% phosphoric acid and the mass ratio of deionized water is 1:(4.0~ 4.5). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: what this embodiment is different from specific embodiment one or two is: the mass fraction described in step one is that the mass ratio of the phosphoric acid of 85% and the pseudo-boehmite of 69% is 1: 0.7; the mass fraction described in step one is that the mass ratio of 85% phosphoric acid and 95% di-n-butylamine is 1:0.8; the mass fraction described in step one is 85% phosphoric acid and mass fraction The mass ratio of 27% silica sol is 1:(0.2-0.8); the mass ratio of phosphoric acid with a mass fraction of 85% and deionized water described in step 1 is 1:4.3. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com