Method for synthesizing SAPO-41 (Phosphoric Acid Silicon-Aluminum-41) molecular sieve by adopting novel template agent

A SAPO-41, a new type of template technology, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of miscellaneous crystals, high preparation cost, unfavorable mass industrial production, etc., and achieve reduced synthesis Cost, low price, the effect of realizing mass industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

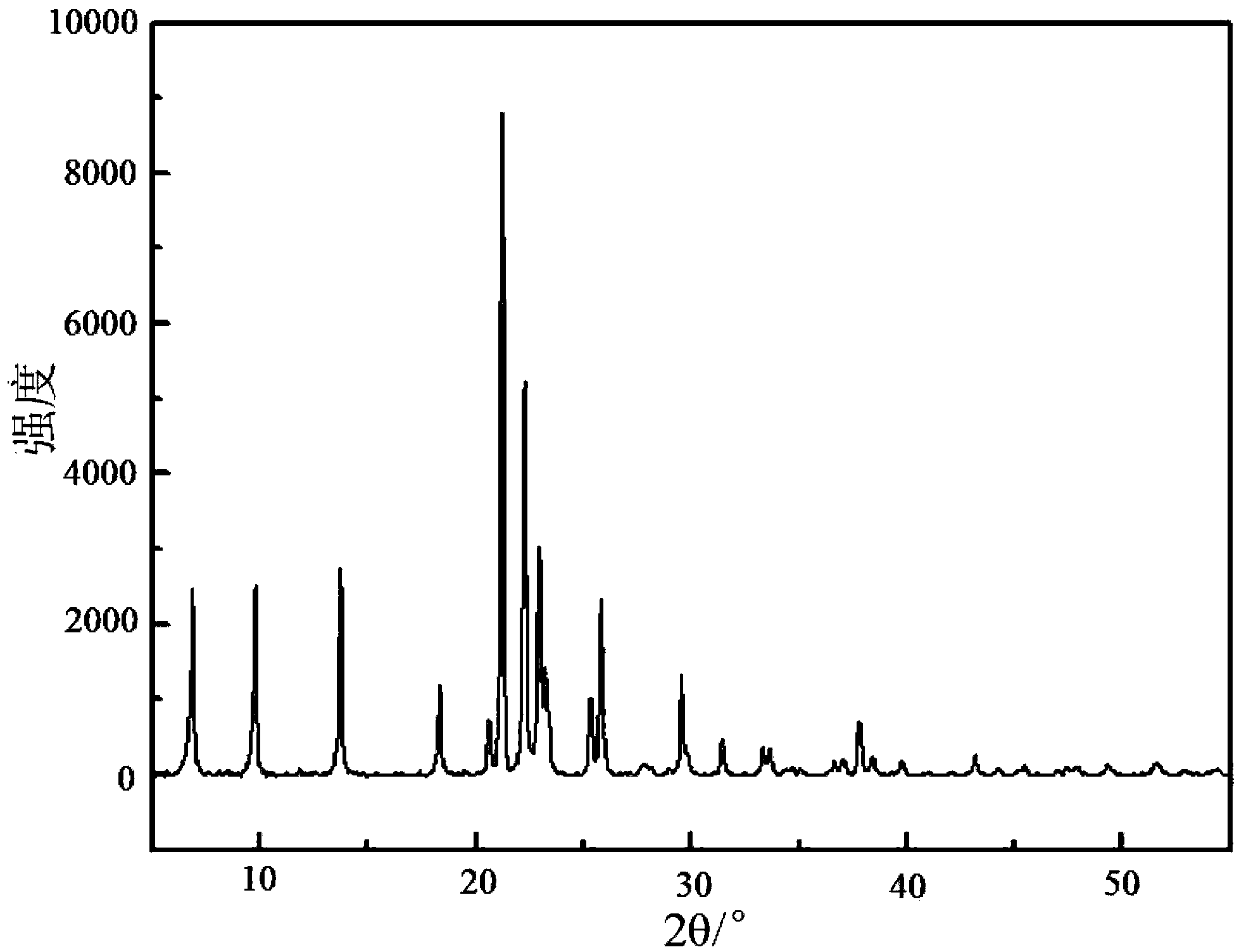

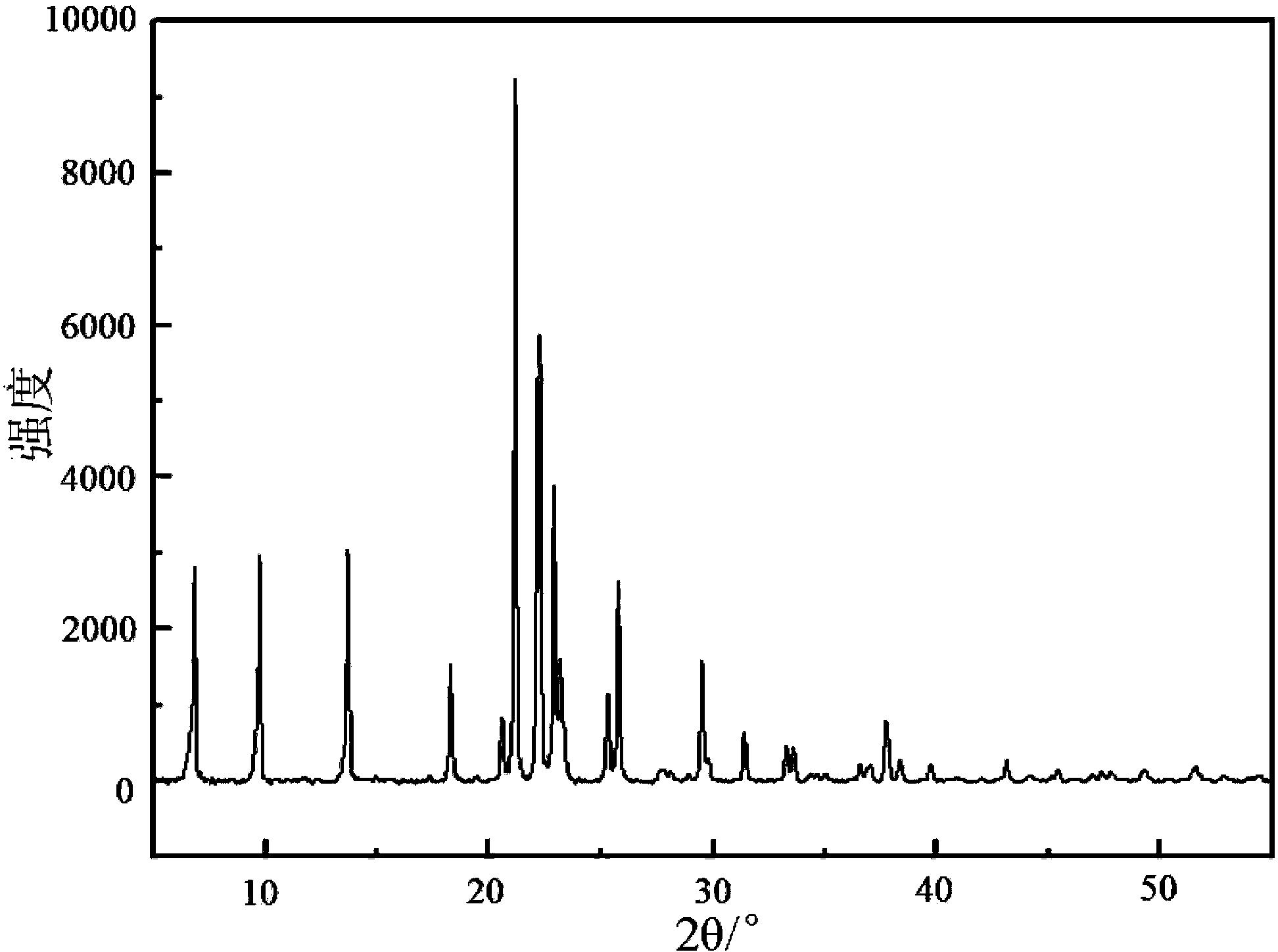

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: this embodiment is a kind of method that adopts novel templating agent to synthesize SAPO-41 molecular sieve, specifically is to carry out according to the following steps:

[0010] 1. Add phosphoric acid, pseudoboehmite, di-n-butylamine and silica sol with a mass fraction of 85% into deionized water in sequence, and stir at a speed of 500r / min~2000r / min for 1h~8h to obtain the initial Gel; 2. Place the initial gel obtained in step 1 in a polytetrafluoroethylene-lined stainless steel crystallization kettle, crystallize at 160°C~200°C for 2h~72h, then cool to room temperature, and cool to room temperature to produce The crystallized product was centrifuged, washed and dried at 100°C~200°C for 10h~24h in sequence, and finally calcined at 500°C~700°C for 4h~30h, and naturally cooled to room temperature to obtain SAPO-41 molecular sieve.

[0011] The mass fraction described in step one of the present embodiment is that the mass ratio of phosphoric a...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass ratio of phosphoric acid with a mass fraction of 85% and pseudo-boehmite described in step one is 1:(0.5~1.9). Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mass fraction of phosphoric acid and di-n-butylamine described in step one is 1:(12~2.1) . Others are the same as the second or third specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com