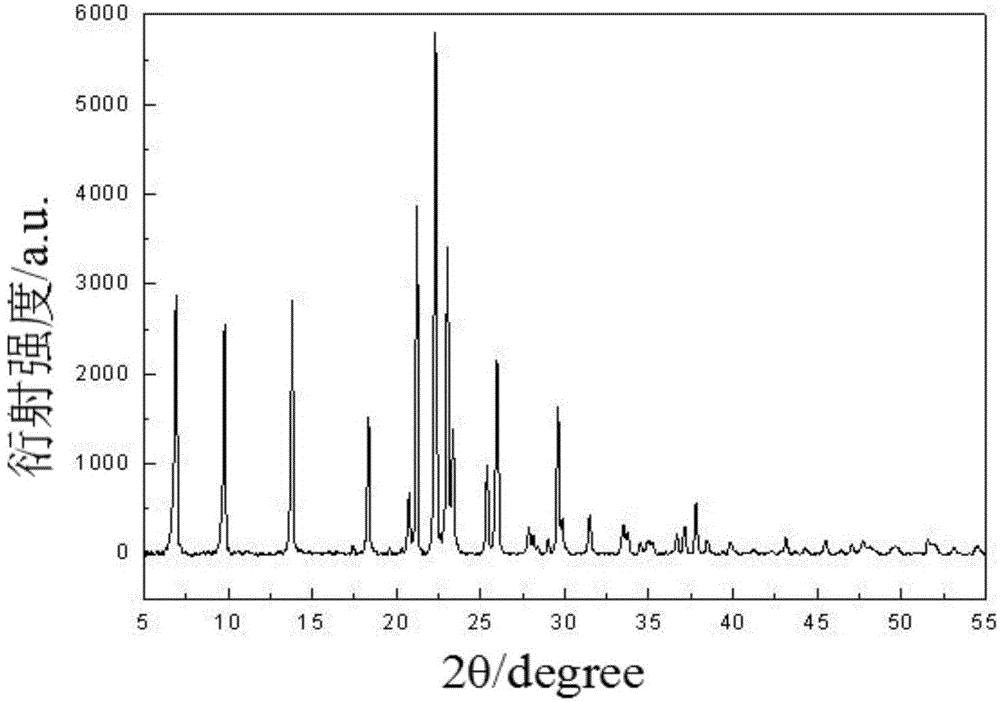

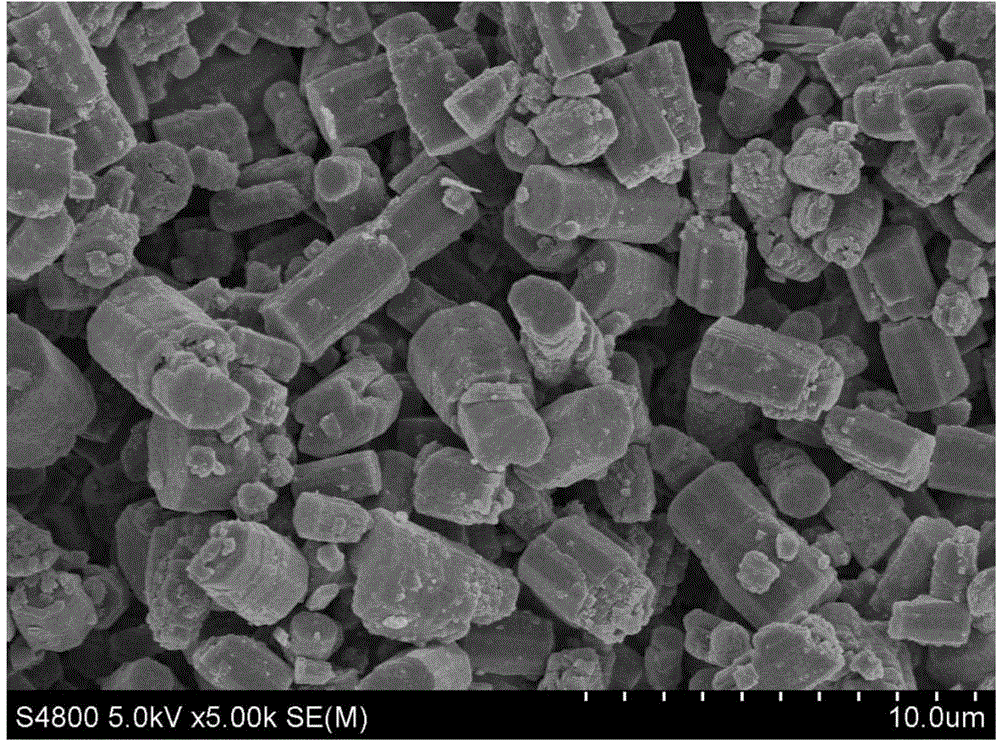

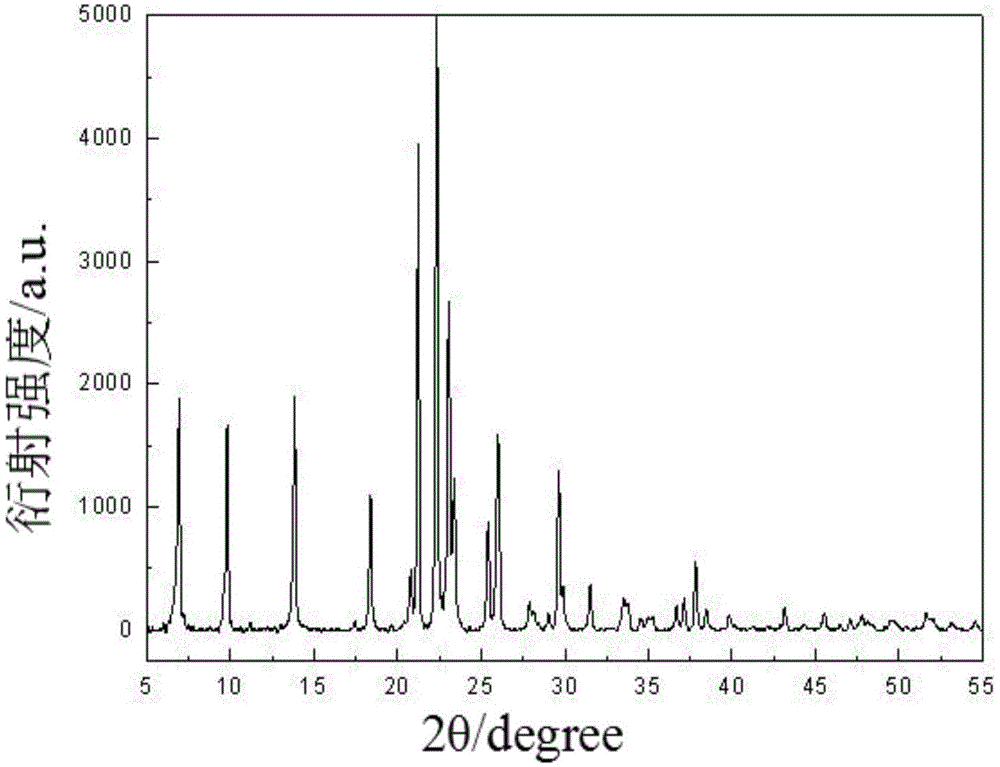

Microwave heating synthesis method of SAPO (Silicoaluminophosphate)-41 molecular sieve

A technology of SAPO-41 and microwave heating, which is applied in the synthesis field of SAPO-41 molecular sieve, can solve the problems of miscellaneous crystals and long crystallization time, and achieve the effects of shortening crystallization time and strong acidity controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the microwave heating synthesis method of a kind of SAPO-41 molecular sieve in the present embodiment is carried out according to the following steps:

[0019] 1. Phosphoric acid with a mass fraction of 80% to 90%, pseudoboehmite with a mass fraction of 65% to 75%, di-n-propylamine with a mass fraction of 95% to 99%, and 20% to 30% The silica sol is added to deionized water in turn, and stirred at a speed of 500r / min to 2000r / min for 1h to 10h to obtain the initial gel; the mass fraction described in step 1 is 80% to 90% of phosphoric acid and mass Fraction is that the mass ratio of the pseudo-boehmite of 65%~75% is 1:(0.5~1.0); The mass fraction described in step 1 is that the phosphoric acid of 80%~90% and the mass fraction are 95%~99% The mass ratio of di-n-propylamine is 1:(0.5~1.8); The mass fraction described in step 1 is that the mass ratio of the phosphoric acid of 80%~90% and the silica sol of 20%~30% is 1: (0.05~1.0); The mass fractio...

specific Embodiment approach 2

[0025] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the phosphoric acid that mass fraction is 80%~90%, the pseudo-boehmite that mass fraction is 65%~75%, the mass fraction is 95%-99% di-n-propylamine and silica sol with a mass fraction of 20%-30% are sequentially added to deionized water, stirred at a speed of 1000r / min-1500r / min for 3h-7h, and the initial gel is obtained. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass fraction described in step one is 80% to 90% of phosphoric acid and 65% to 75% of quasi-thin water The mass ratio of bauxite is 1:(0.6~0.8); The mass fraction described in the step 1 is that the mass fraction of 80%~90% phosphoric acid and the mass fraction are 95%~99% of the mass ratio of di-n-propylamine is 1:( 1.0~1.5); The mass fraction described in step one is that the mass ratio of the phosphoric acid of 80%~90% and the silica sol of 20%~30% is 1:(0.1~0.7); Described in step one The mass fraction of phosphoric acid is 80% to 90% and the mass ratio of deionized water is 1: (3.0 to 4.1). Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com