Zinc hydrometallurgy process favorable for floatation silver and adopted precipitating silver mixture

A hydrometallurgical zinc smelting and process technology, applied in the field of non-ferrous metal smelting, can solve the problems of reduced silver enrichment and recovery rate, difficult to recover economically, and loss of silver dispersion, so as to improve electrolysis efficiency, reduce silver loss and save The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

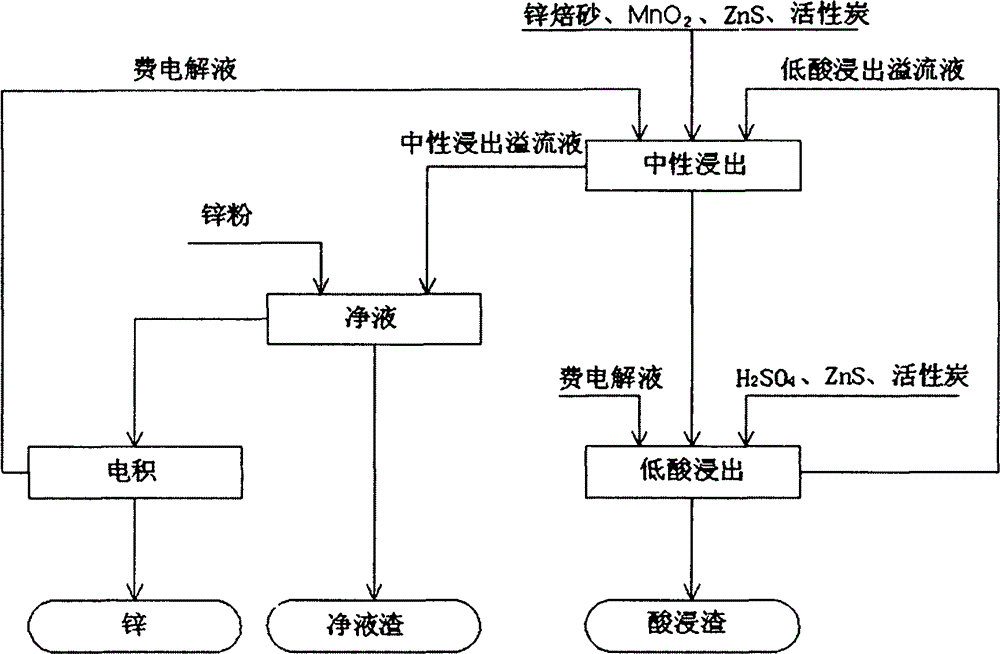

[0029] Embodiment 1: as figure 1 As shown, it belongs to the conventional leaching process method in hydrometallurgy: a kind of hydrometallurgy technique that is beneficial to flotation silver, and it comprises following several steps: it comprises following several steps: (1) neutral leaching : adding zinc calcined sand and manganese dioxide to the waste electrolyte and low-acid leaching overflow liquid for neutral leaching to produce neutral leaching overflow liquid and neutral leaching underflow liquid; (2) net liquid: neutral leaching Add zinc powder to the overflow liquid to clean the liquid, produce purified liquid and clean liquid slag, purify the liquid to extract zinc and produce waste electrolyte; (3) low-acid leaching: add waste electrolyte and waste electrolyte to the neutral leaching bottom flow Dilute sulfuric acid is used for low-acid leaching to produce low-acid leaching overflow and acid leaching residue. Add zinc sulfide and activated carbon powder in the ne...

Embodiment 2

[0030] Embodiment 2: Other schemes are the same as Example 1, and the difference is that zinc sulfide and activated carbon powder are added in the neutral leaching and low-acid leaching steps, and the addition of zinc sulfide and activated carbon powder is based on the total amount of zinc calcined sand in the whole process As a basis, add 0.2 kg of zinc sulfide and 0.6 kg of activated carbon powder per 1 ton of zinc calcine in the neutral leaching step; add 0.2 kg of zinc sulfide and 0.6 kg of activated carbon powder per 1 ton of zinc calcine in the low-acid leaching step. The powder fineness is 200 mesh.

Embodiment 3

[0031] Embodiment 3: Other schemes are the same as Example 1, and the difference is that zinc sulfide and activated carbon powder are added in the neutral leaching and low-acid leaching steps, and the addition of zinc sulfide and activated carbon powder is based on the total amount of zinc calcine in the whole process As a basis, add 0.25 kg of zinc sulfide and 0.7 kg of activated carbon powder per 1 ton of zinc calcine in the neutral leaching step; add 0.25 kg of zinc sulfide and 0.7 kg of activated carbon powder per 1 ton of zinc calcine in the low-acid leaching step The powder fineness is 400 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com