Slag Separation Gate Valve

A technology of gate valve and water slag, which is applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of punctured rubber pipe closure, sewage outflow, impreciseness, etc., and achieve the effects of avoiding pollution, facilitating recycling, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

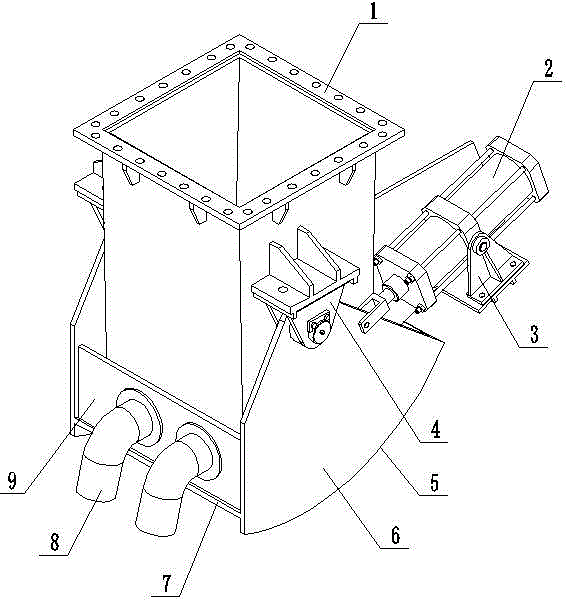

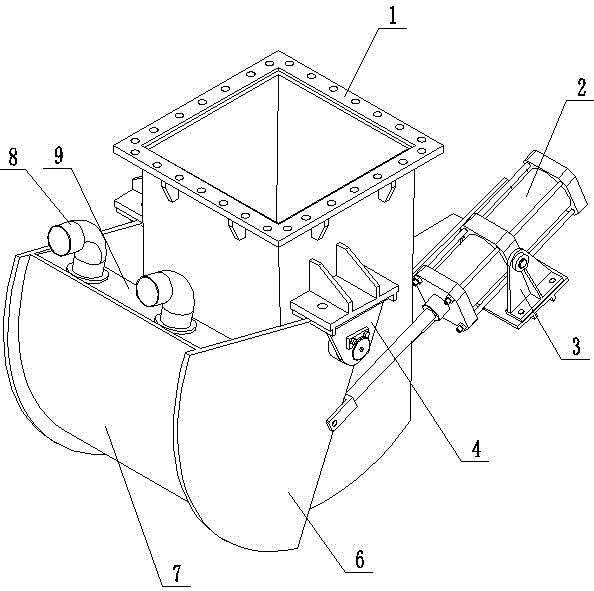

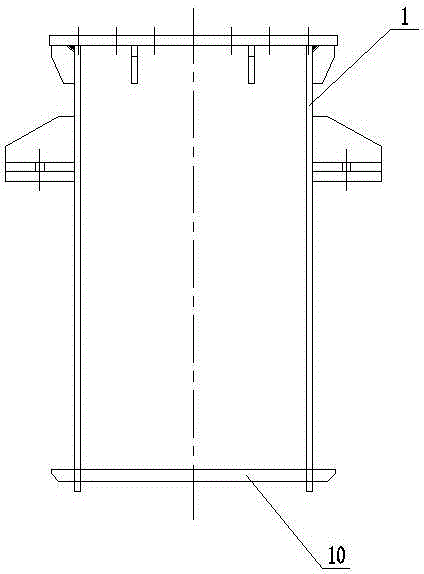

[0015] Such as figure 1 , 2 , 3, the present invention mainly includes a valve body 1, the discharge port of the valve body 1 is connected with a scraper 10, a driving device mounting bracket 3 and two gate swing brackets 4 are connected on the valve body 1, and the driving device mounting bracket 3 is connected The drive device 2, the drive device 2 can be in the form of electro-hydraulic push rod drive, cylinder drive, hydraulic cylinder drive, electric push rod drive and electric rotary device drive. The telescopic end of the driving device 2 is hinged to the gate 5. The gate 5 includes an arc-shaped gate 7, a water stop 9, an overflow 8 and two fan-shaped plates 6, which are respectively arranged on both sides of the valve body 1. , two fan-shaped plates 6 are hingedly connected with corresponding gate swing brackets 4 respectively. The arc-shaped gate 7 is arranged between two fan-shaped plates 6, and the two sides of the arc-shaped gate 7 are respectively welded with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com