A rapid indoor evaluation method for oil removal effect of oil displacing agent

An oil-displacing agent and oil-washing technology is applied in the field of rapid indoor evaluation of the oil-washing effect of oil-displacing agents, which can solve the problems of lack of rapid evaluation methods, ineffective quality control of surfactant products, and troublesome testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides a kind of indoor rapid evaluation method of the oil removal effect of the oil displacing agent, comprising the following steps:

[0067] Mix 80-100 mesh quartz sand with different crude oils evenly to obtain oil sands (as shown in Table 3). The mass ratio of crude oil to quartz sands is 1:7, and then the oil sands are treated at the formation temperature of the reservoir at 55°C. 96 hours of constant temperature aging; the parameters of crude oil and formation simulated water are shown in Table 4

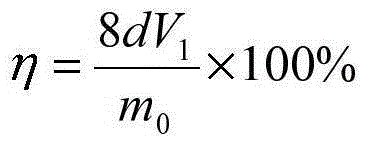

[0068] Put an appropriate amount of aged oil sand into the measuring cylinder of the self-priming instrument, then add part of the oil displacement agent solution (prepared by oil displacement agent and formation simulated water, the concentration of this series of oil displacement agent solution is 0.20wt%), seal Finally, use an air-bath oscillator to vibrate for 2 hours, then take out and add the remaining oil-displacing agent solution, cover the gr...

Embodiment 2

[0076] This embodiment provides an indoor rapid evaluation method for the oil-washing effect of an oil-displacing agent, which is for three kinds of oil-displacing agents with the same main agent (the main agent is an anionic surfactant sodium polyacrylate, and the auxiliary agent is a nonionic surfactant agent, the main component of the auxiliary agent is Tween 80, and the content of the auxiliary agent of the three kinds of oil displacing agents is not the same), the method for evaluating the oil washing effect includes the following steps:

[0077] Mix Liaohe Jin 16 crude oil with 80-100 mesh quartz sand, the mass ratio of crude oil to quartz sand is 7:1, and then carry out constant temperature aging for 72 hours on the oil sand at the formation temperature of the reservoir at 55°C;

[0078] Put an appropriate amount of aged oil sand into the measuring cylinder of the self-priming instrument, and then add part of the oil-displacing agent solution (using three kinds of oil-di...

Embodiment 3

[0086] This embodiment provides an indoor rapid evaluation method for the oil-washing effect of an oil-displacing agent, which is a method for evaluating the oil-washing effect of a series of oil-displacing agents with the same main agent and different auxiliary agents, including the following steps:

[0087] Mix crude oil from Jilin Honggang test area with 80-100 mesh quartz sand, the mass ratio of crude oil to quartz sand is 7:1, and then carry out constant temperature aging for 72 hours on the oil sand at the formation temperature of the reservoir at 50°C;

[0088] Put an appropriate amount of aged oil sand into the measuring cylinder of the self-priming instrument, then add part of the oil-displacing agent solution (the concentration of the oil-displacing agent solution is 0.20wt%), and use an air-bath oscillator after sealing (the frequency of the air-bath oscillation is 150 rpm) at 50°C for 2 hours of shaking treatment, then take out and add the remaining oil displacing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com