Measuring method of pectin content in tobaccos and tobacco products

A technology for tobacco products and determination methods, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of long processing time, affecting the accuracy and reproducibility of analysis results, and complicated operation, and achieves shortened operation and time. Application prospect, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

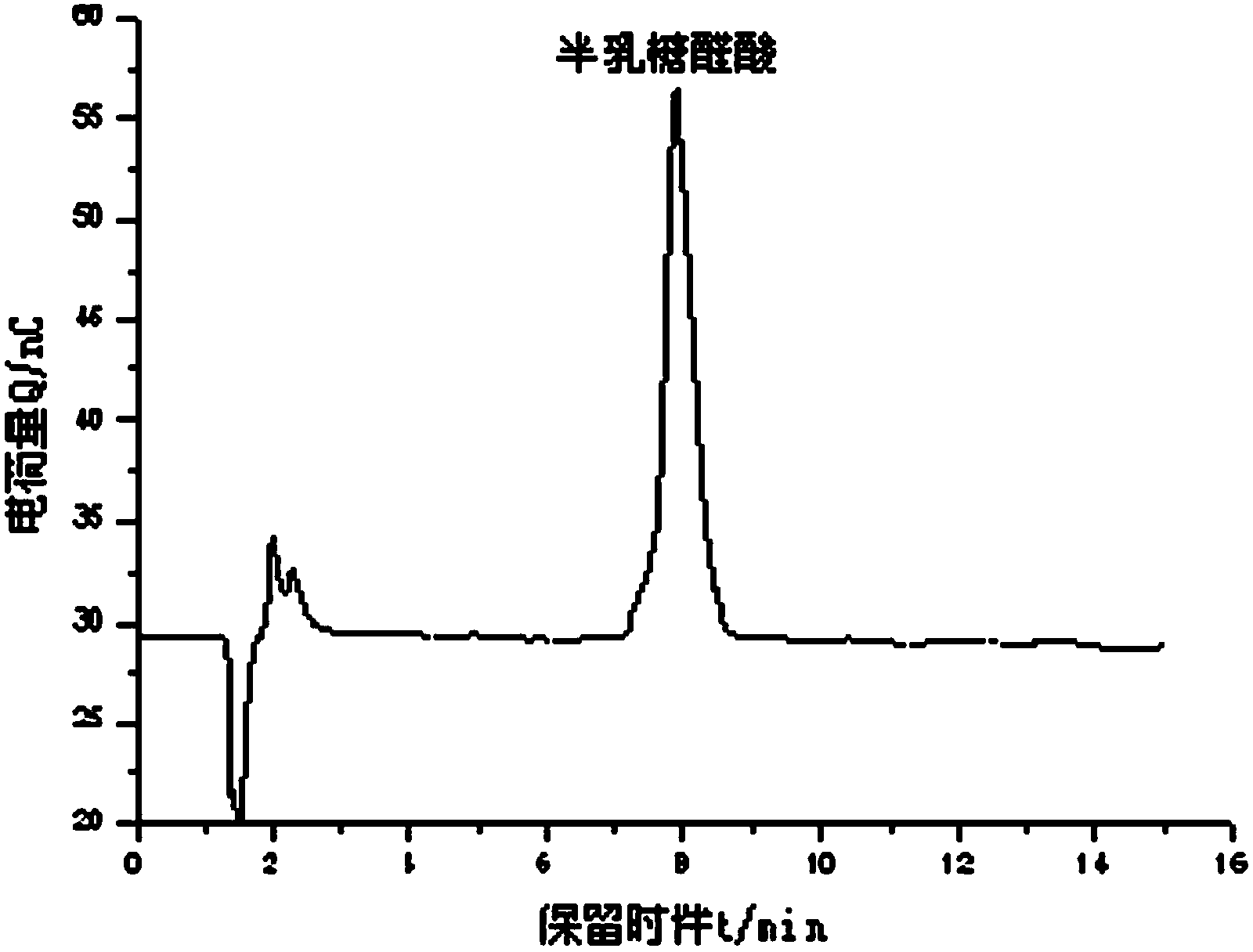

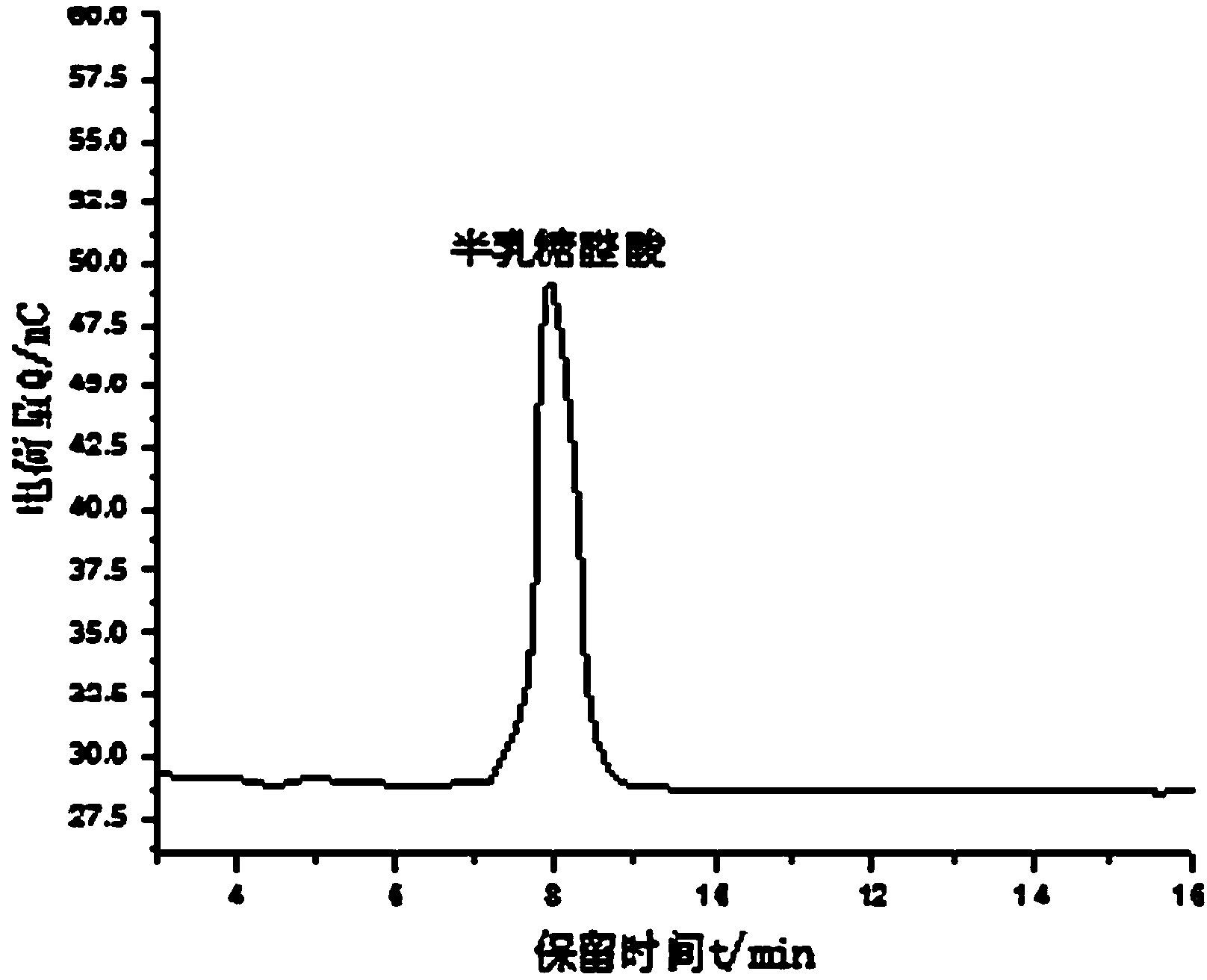

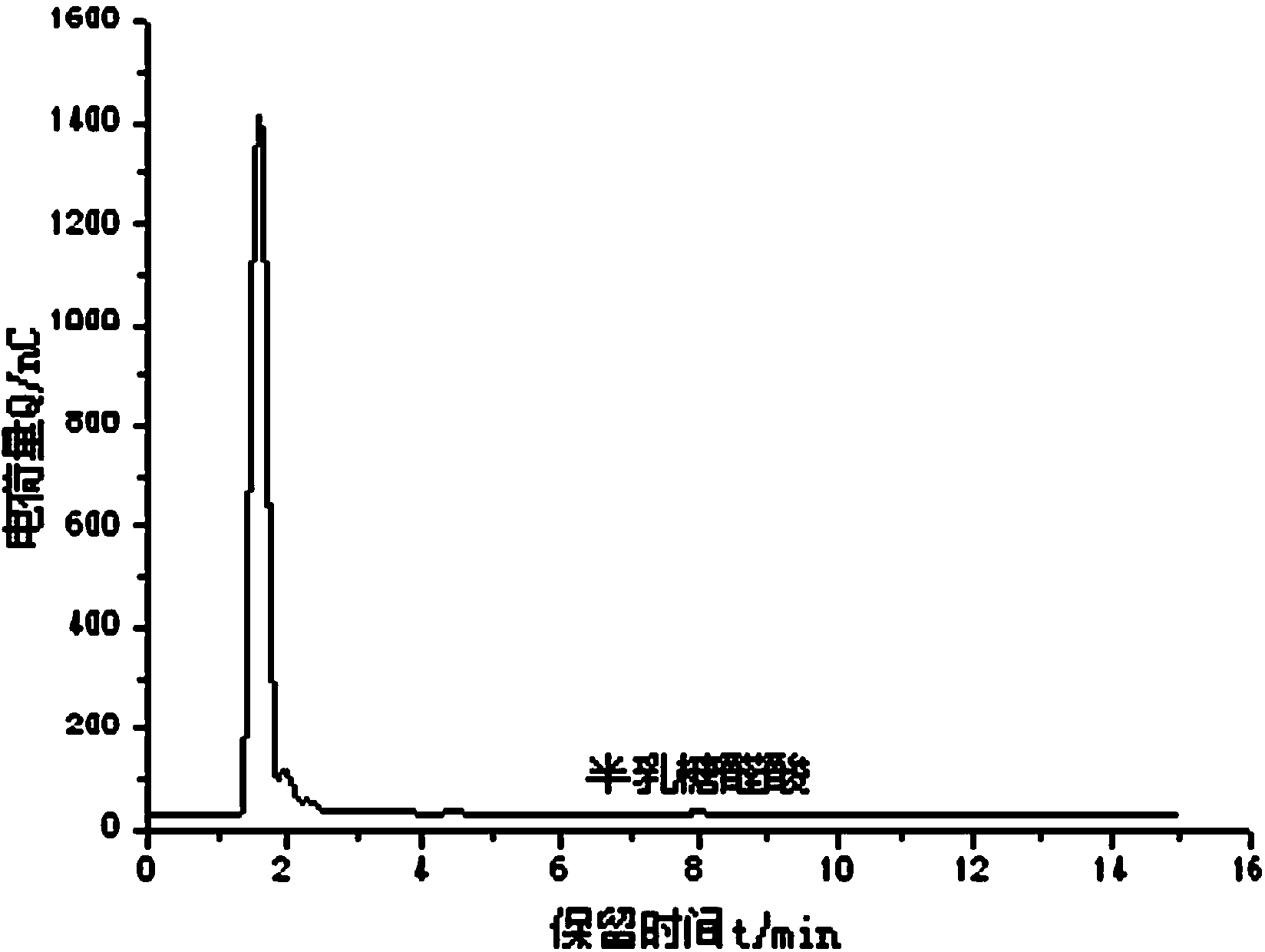

[0066] Sample pretreatment

[0067] A. Tobacco samples were crushed with a pulverizer, passed through a 40-mesh sieve, and their moisture content was determined w , accurately weighed 0.5 g (accurate to 0.0001 g) of tobacco sample, placed in a 250 mL round bottom flask, accurately added 100 mL of hydrochloric acid-ethanol solution with a hydrogen ion concentration of 0.05 mol / L and an alcohol concentration of 80%, and the round Place the bottom flask on the electric heating mantle, connect the condenser, heat and reflux for 1 h, suction filter while it is hot, rinse with hot water three times, and dilute the filtrate to 200 mL to obtain solution a;

[0068] B. Transfer the residue of the above suction-filtered sample to a 200 mL ground-mouth Erlenmeyer flask, add 100 mL of acetic acid / sodium acetate buffer solution and 40 μL of pectinase solution, enzymatically hydrolyze in a water bath at 53 °C for 3 h, suction filter, and dilute the filtrate to 200 mL to obtain solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com