Organic luminous device

A technology of organic light-emitting device and organic light-emitting layer, which is used in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

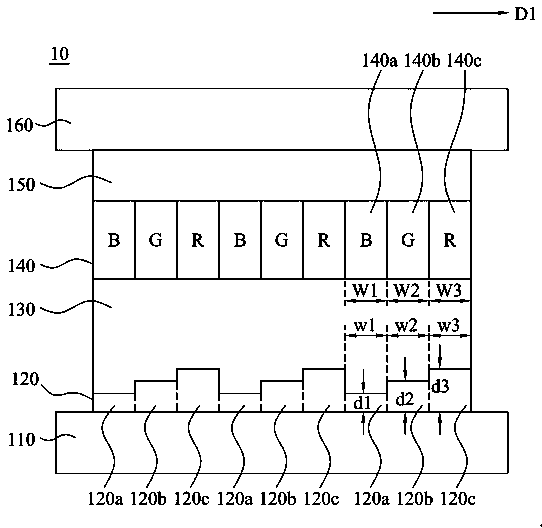

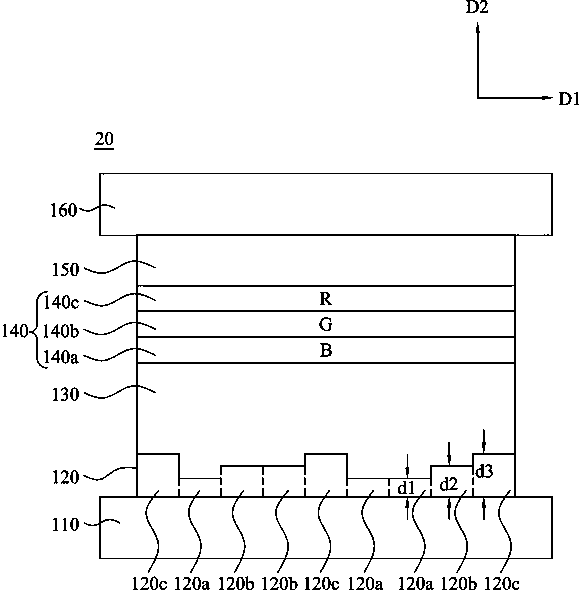

[0041] see figure 1 , figure 1 is a schematic cross-sectional view illustrating an organic light emitting device 10 according to an embodiment of the present invention. The organic light emitting device 10 includes a transparent substrate 110 , an intermediate layer 120 , a first electrode 130 , an organic light emitting layer 140 and a second electrode 150 .

[0042] The material of the transparent substrate 110 can be glass or plastic. Glass has a refractive index of about 1.52. The plastic can be, for example, acrylic resin (Acrylic), epoxy resin (Epoxy), polyethylene terephthalate (Polyethylene terephthalate, PET) or polycarbonate (Polycarbonate, PC), and its refractive index is about 1.49 to Between 1.6.

[0043] The first electrode 130 is located above the transparent substrate 110 . The material of the first electrode 130 can be, for example, indium tin oxide (Indium thin oxide, ITO) or other suitable transparent conductive materials. The refractive index of indiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com