Phase measuring device for laser interference photoetching system and using method thereof

A laser interference lithography and phase measurement technology, which is applied in the field of optical instruments and meters, can solve the problems of poor anti-interference ability of homodyne phase measurement interferometer, inability to interfere with fringe control of exposure system, CCD resolution and frame rate limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means and effects of the present invention for solving technical problems, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the provided accompanying drawings are schematic and mutually exclusive They are not drawn to scale or scale, and therefore the drawings and specific examples are not intended to limit the scope of protection claimed by the invention.

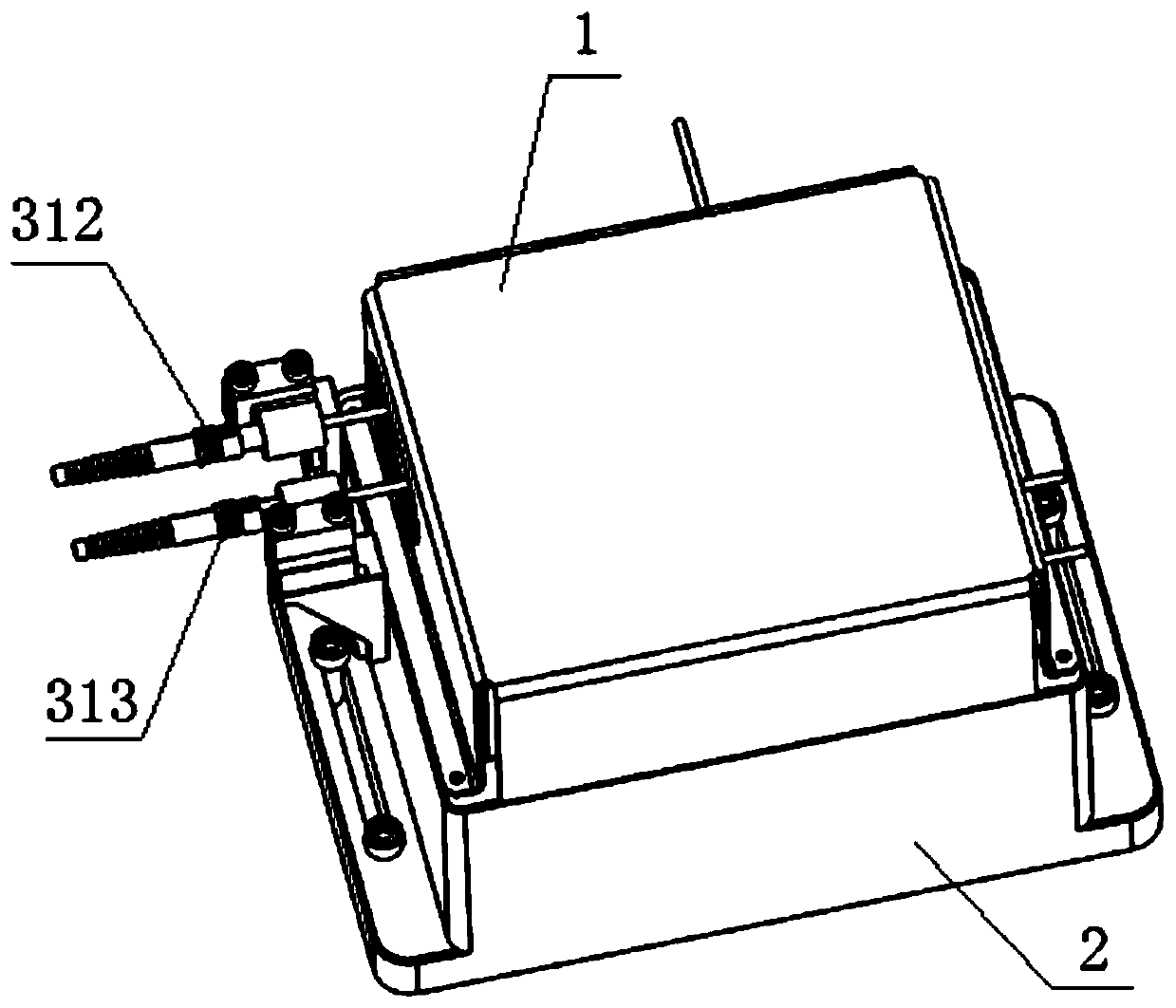

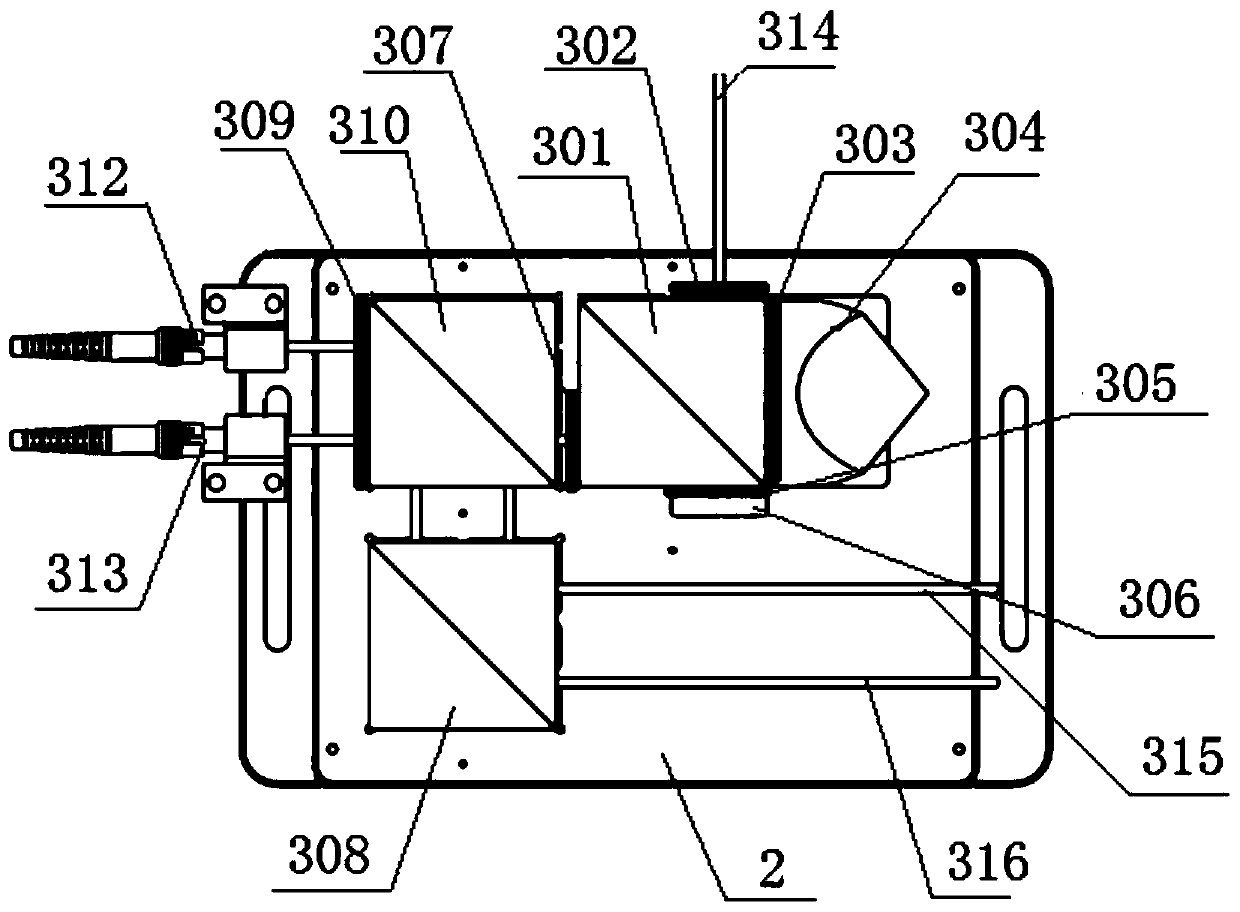

[0026] Such as figure 1 The shown optional embodiment of the phase measurement device used in the laser interference lithography system, the device is in the shape of a square box, and the optical system components are in the box formed by the shell 1 and the base 2, and the first photodetector 312 and the second photodetector 313 protrude from the outside of the box, and the housing 1 is fixedly connected to the base 2 with screws. The first photodetector 312 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com