Process for applying polymeric coating on cork stoppers

A polymer coating, cork technology, applied in the direction of coating, liquid coating device on the surface, closure plug, etc., can solve the problem of no effect, achieve the effect of low barrier effect and migration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Example 1 - Preparation of Polymer Formulation

[0084] Prior to step 1 of the invention, the polymer formulation for application on the cork was prepared. A preferred formulation is prepared using polydimethylsiloxane (PDMS) with vinyl groups, a crosslinker and a catalyst. The amount of catalyst added to the formulation was about 1% to make the final PDMS formulation compatible with human food (food grade).

[0085] In Tables 1 and 2 below, the main characteristics of the polymer formulation are described, respectively, as well as the percentage of each component based on the total weight of the formulation.

[0086] Table 1 - Polymer Formulations

[0087]

[0088] Table 2 - Weight Percentage of Formulation Components

[0089] components

Embodiment 2

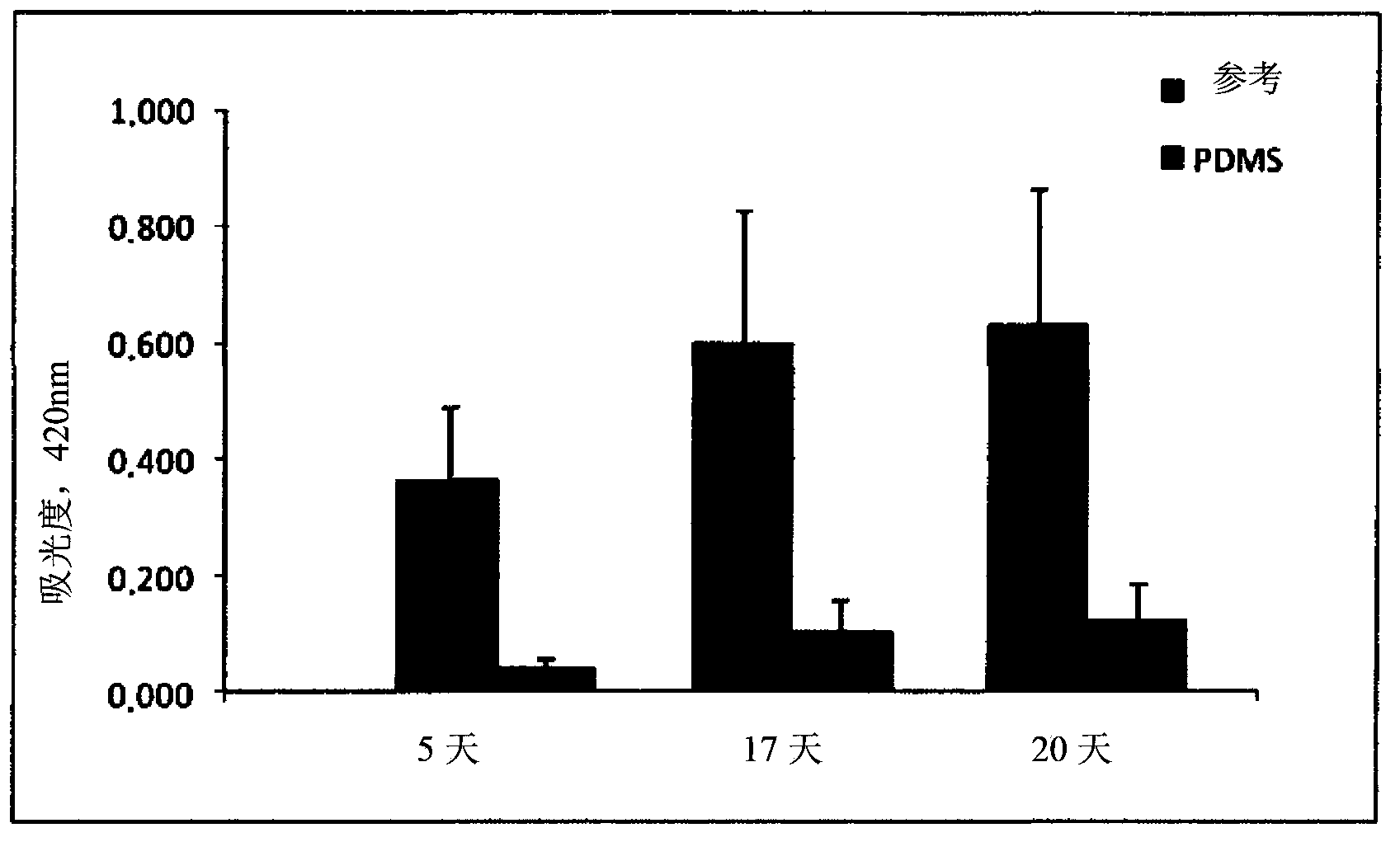

[0090] Example 2 - Use of a PDMS coating on cork stoppers according to the method of the invention. Evaluation of the extraction of colored compounds after immersion treatment of treated plugs (Accelerated Regimen)

[0091] This example concerns the use of a PDMS coating of the type defined in example 1 on cork stoppers by the method of the invention. PDMS polymer suspensions were prepared by adding crosslinkers and catalysts to PDMS according to Example 1.

[0092]Film deposition has been done on 100 corks by immersion in a mixing rotating drum for about 15 minutes at room temperature of about 20° C. (by the method of the invention). The plugs were washed and exhibited a moisture content of about 15% prior to tumble mixing.

[0093] After this first step, the cork is placed in a hollow perforated rotating drum to cure the film. The temperature of the rotating drum was 60°C and the temperature transition rate was set at 3°C / min until the temperature reached 90°C. Next, the...

Embodiment 3

[0098] Example 3 - Use of a PDMS coating on cork stoppers according to the method of the invention. Evaluation of the extraction of colored compounds from treated conventional plugs (Normal Regimen)

[0099] The conditions for using the method of the present invention are the same as those for the aforementioned assays.

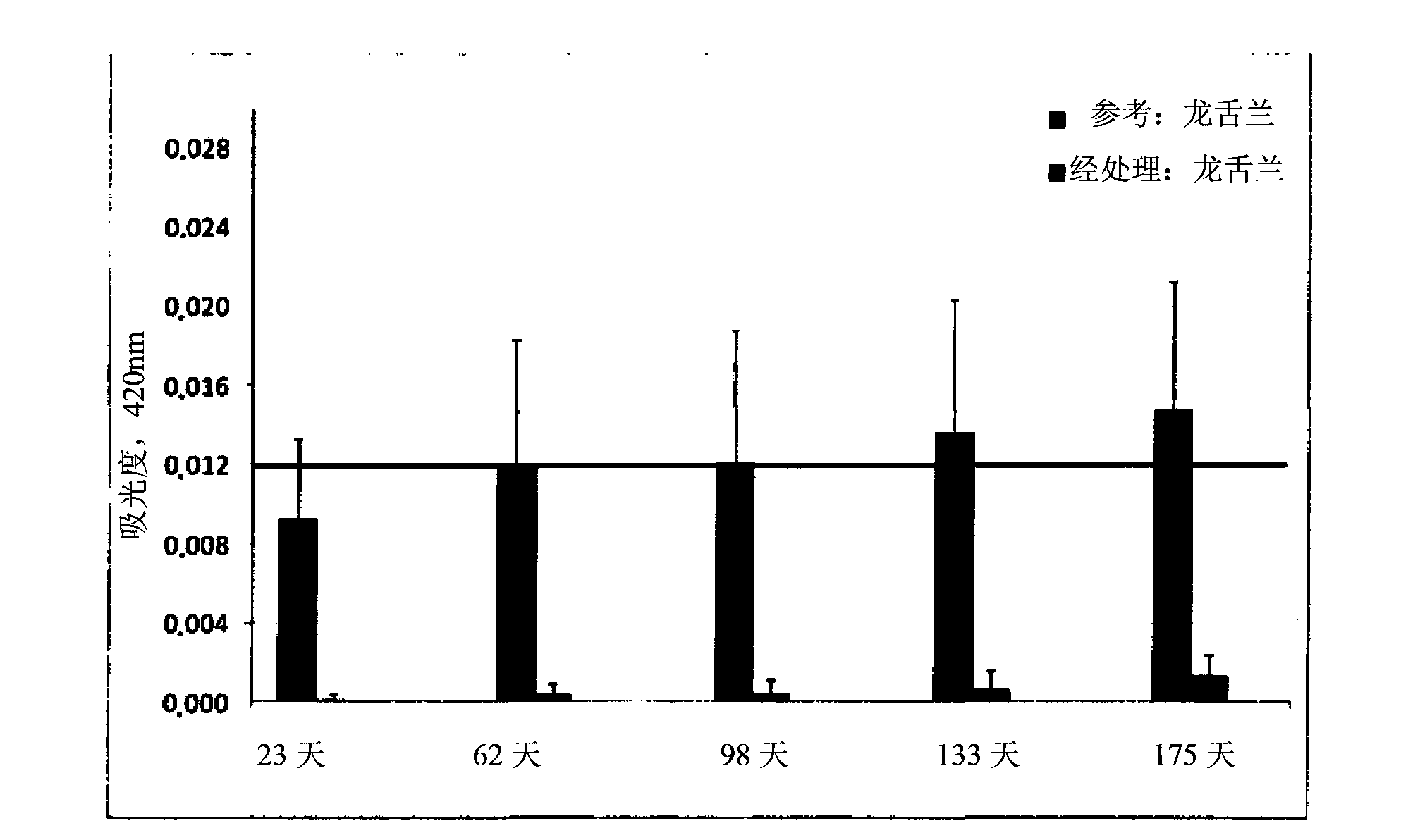

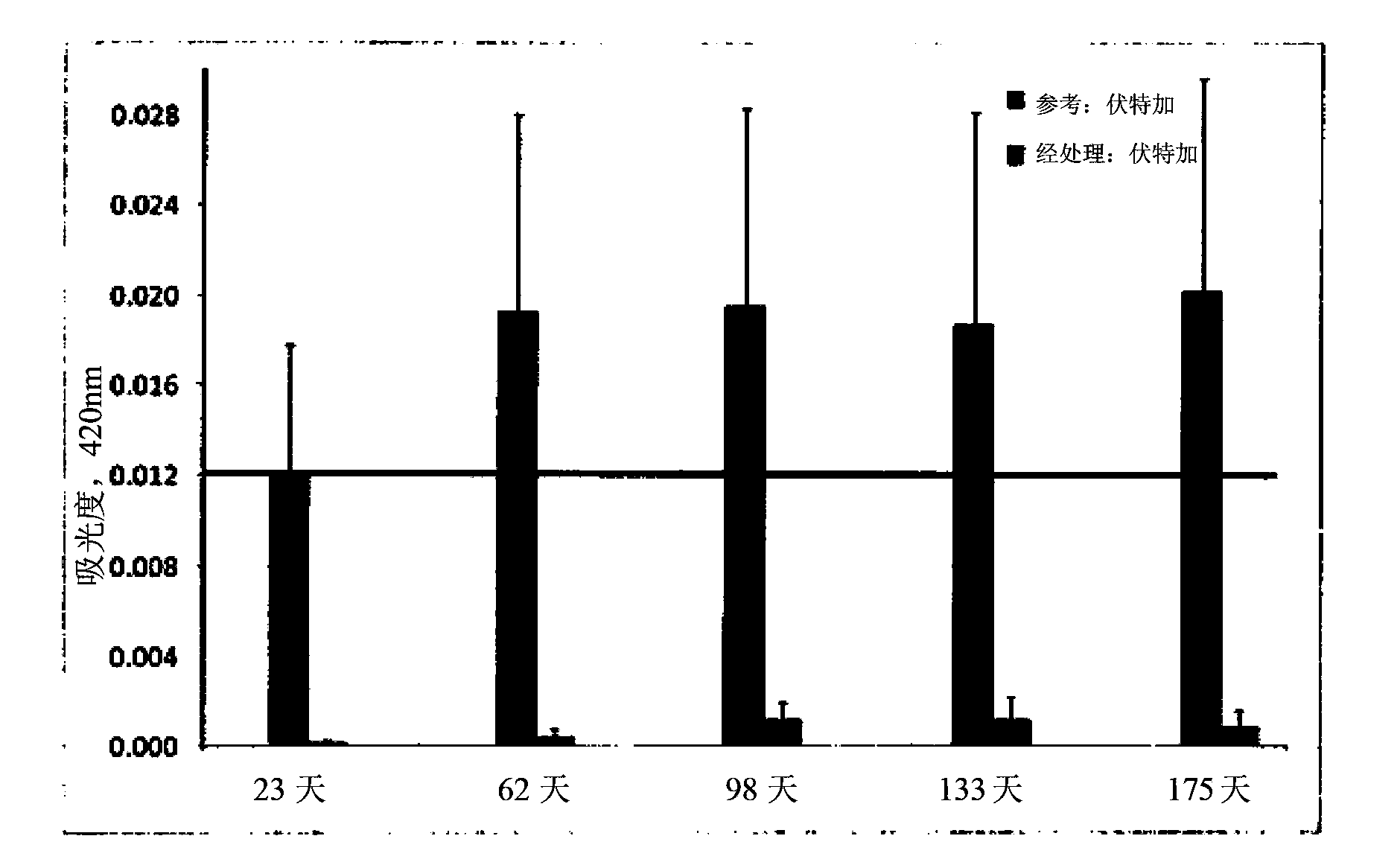

[0100] After using the method as in Example 2, the resulting coated stoppers were stoppered to seal bottles containing different white alcoholic beverages.

[0101] A bottle containing agave, vodka, gin and a hydroalcoholic solution similar to Example 2 was used. The evaluation was carried out under the normal protocol, ie the evaluation of treated and untreated corks in bottles. In this way, non-accelerated conditions are used to extract those undesired compounds of the beverage.

[0102] Figure 2 to Figure 5 Several graphs are shown of the absorbance at 420 nm as a function of time for several beverages in contact with treated plugs (PDMS) and untreate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com