Preparation method of gas purification membrane with antibacterial function

A gas purification and functional technology, applied in the field of membrane preparation and modification, to achieve the effect of large adsorption capacity, simple equipment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

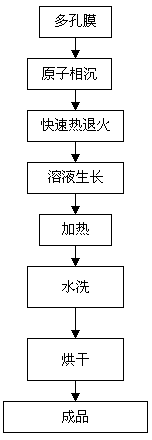

[0039] Such as figure 1 As shown, the preparation method of the present invention is as follows: use atomic deposition instrument ALD to deposit a layer of zinc oxide film on the surface of polytetrafluoroethylene porous membrane (0.5um), the atomic deposition cycle is 200cyl, the carrier pressure is 1Torr, and the carrier gas volume is 15sccm. After 300s of high-temperature aerobic thermal annealing at 300°C, take it out after cooling, put it into a hydrothermal kettle containing 0.1Mol / L zinc acetate and 25mMol / L hexamethylenetetramine aqueous solution, place it vertically, and put the hydrothermal kettle in an oven , 90 ℃ constant temperature storage 5h, that is.

[0040]The gas purification membrane prepared in this example was measured by a scanning electron microscope S-4800, and there were linear zinc oxide crystals on the surface of the membrane (see figure 2 ). The thickness of the gas purification membrane is 0.03mM, and the pore size range is 0.1~0.5um.

[0041...

Embodiment 2

[0043] Such as figure 1 As shown, the preparation method of the present invention is as follows: use atomic deposition instrument ALD to deposit a layer of zinc oxide film on the surface of polytetrafluoroethylene porous membrane (aperture 1um), atomic deposition cycle 100cyl, carrier pressure is 0.5Torr, carrier gas volume 10sccm. After aerobic thermal annealing at a high temperature of 100°C for 300s, put it into a hydrothermal kettle containing 0.05Mol / L zinc acetate and 25mMol / L hexamethylenetetramine aqueous solution, place it vertically, and put the hydrothermal kettle in an oven at 50℃ Storing at constant temperature for 18h, that is.

[0044] The gas purification membrane prepared in this example is measured by a scanning electron microscope s-4800, and the surface of the membrane is formed with linear zinc oxide crystals, which are relatively dense (see figure 2 ). The thickness of the gas purification membrane is 0.1mM, and the pore size range is 0.5~1um.

[004...

Embodiment 3

[0047] Such as figure 1 As shown, the preparation method of the present invention is as follows: use an atomic deposition instrument ALD to deposit a layer of zinc oxide film on the surface of a polytetrafluoroethylene porous membrane (pore size 5um), the atomic deposition cycle is 300cyl, the carrier pressure is 2Torr, and the carrier gas volume is 20sccm. After aerobic thermal annealing at a high temperature of 300°C for 200s, put it into a hydrothermal kettle containing 0.1mMol / L zinc acetate and 25mMol / L hexamethylenetetramine aqueous solution, place it vertically, and put the hydrothermal kettle in an oven at 95℃ Store at constant temperature for 3h, that is.

[0048] The gas purification membrane prepared in this example is measured by s-4800, and uniform linear zinc oxide crystals are formed on the surface of the membrane, which is very dense and uniform (see figure 2 ). The thickness of the gas purification membrane is 1mM, and the pore size ranges from 1 to 5um. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap