Roller shaft assembly having air cooling structure and used for crushing machine and air cooling roller shaft type crushing machine

An air-cooled structure and crusher technology, applied in grain processing, etc., can solve problems such as bearing overheating, high product cost, and high operating cost, and achieve the effects of improving surface hardness and wear resistance, improving linear stiffness, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

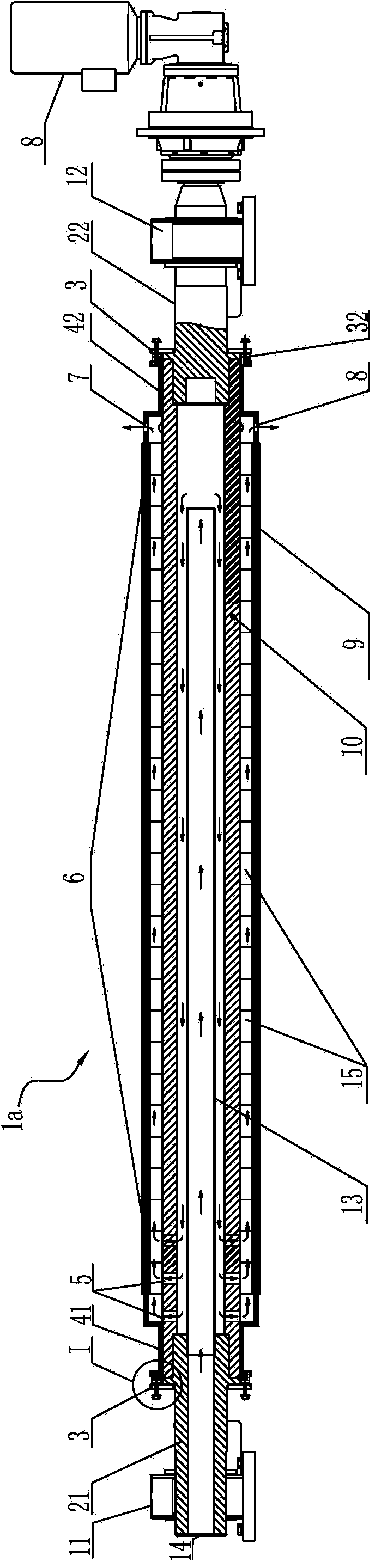

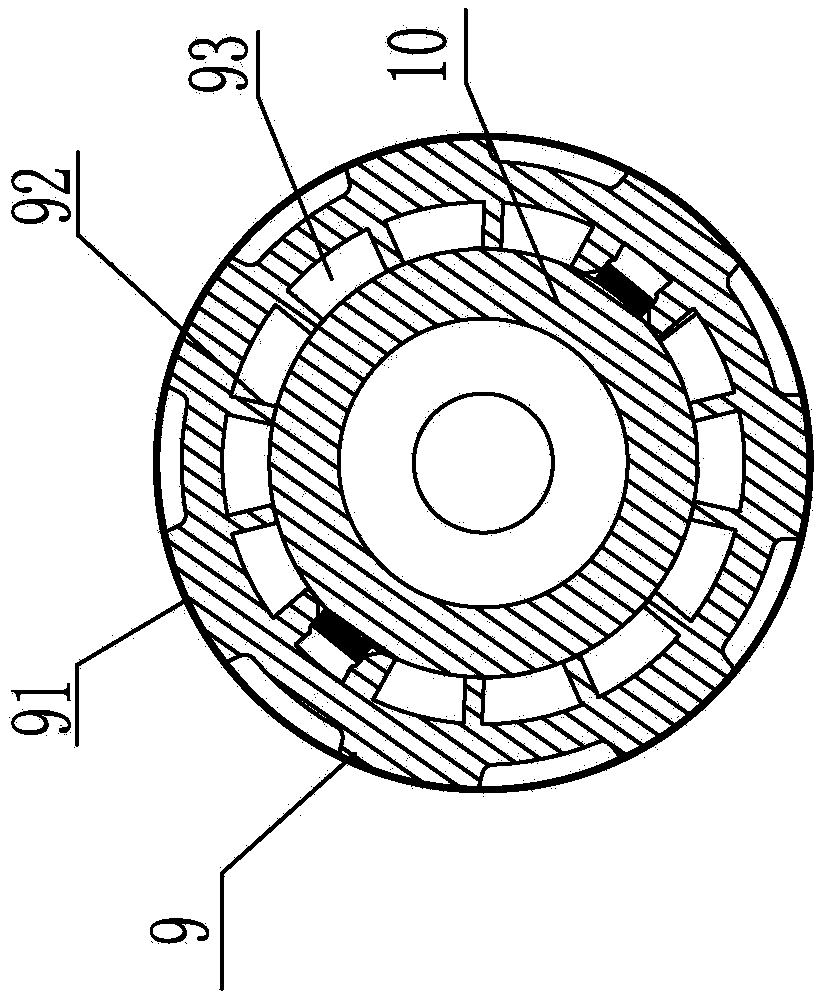

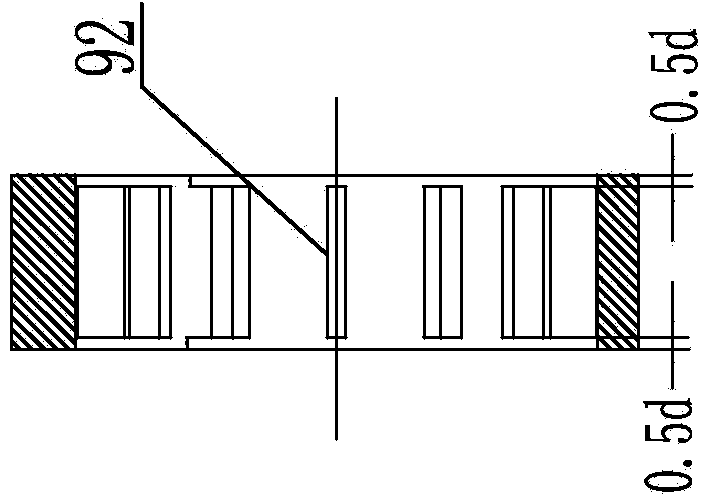

[0028] Figure 1 to Figure 4 It shows a roller shaft assembly 1a for a crusher with an air-cooled structure, including a roller shaft composed of a core tube 10 and a roller sleeve 6 formed of several parallel toothed rollers 9 fixedly fitted thereon One end of the core tube 10 is the driving end and is connected to the driving reduction motor 8 through the driving end shaft head 22 supported on a bearing seat 12, and the other end is the follower end and is supported on the other side by the tubular follower end shaft head 21. On a bearing seat 11, the two ends of the roller sleeve are respectively provided with a roller sleeve limit flange 35, which is characterized in that the outer port of the tubular follower end shaft head 21 is the air inlet 14, and the inner port is sealed and connected horizontally. To the air duct 13 in the core tube close to the shaft head of the driving end; the roller body of the toothed roller 9 is provided with a roller air duct and is connected...

Embodiment 2

[0032] Figure 5 ~ Figure 8 It shows an air-cooled roller crusher, which includes a base 4a, a casing 2a arranged on the base 4a, and multiple roller shaft assemblies 1a arranged in parallel and paired in the casing. In this embodiment Two pairs of four roller shaft assemblies are provided, a material guide plate 3a is provided on the feeding side of the casing, and a casing cooling pipeline 6a is also arranged around the casing. It is characterized in that the roller shaft assembly adopts the crusher roller shaft assembly 1a with an air-cooled structure in Embodiment 1, and is provided with air supply ducts respectively connected to the air inlets 14 of the follow-up end shaft head 21 5a. In actual production, the number of roller shaft assemblies for each device is 2-3 pairs, and one roller shaft assembly can be added according to the needs of use, which can be used as a material guide roller. The quantity of the toothed rollers 9 constituting the roller cover 6 is determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com