Forging press control method and control system of forging press

A control method and technology for a control system, which are applied in the field of forging press control and its control system, can solve the problems affecting the quality of forgings, easily fluctuating the moving speed of the beam, and crawling on the beam, achieving simple structure, easy popularization and application, Safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The control method for a forging press and the control system thereof according to the present invention can be used not only for a large die forging press for stable operation but also for a small die forging press for stable operation.

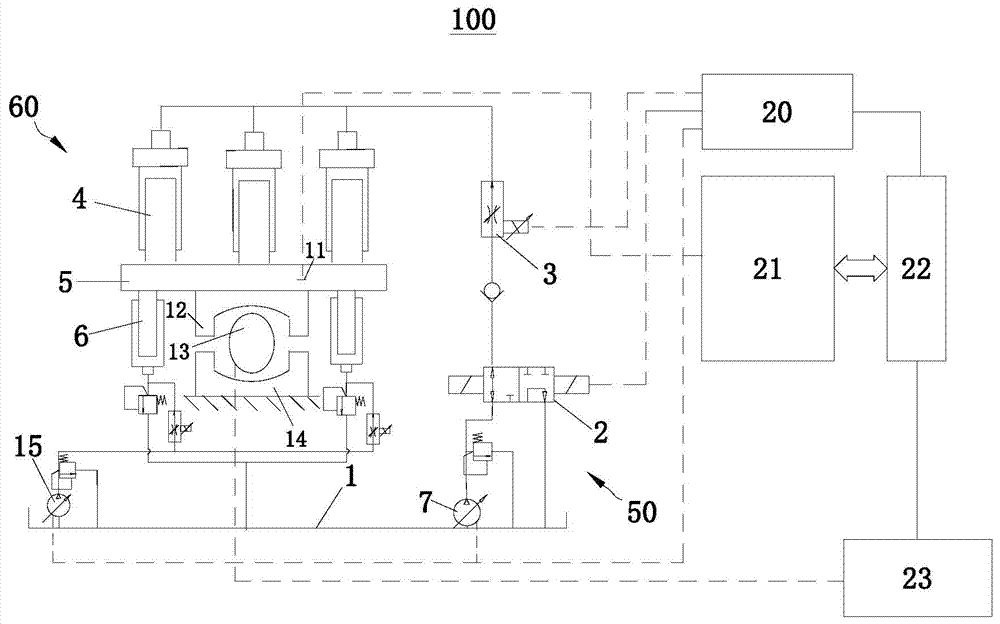

[0027] Such as figure 1 As shown, the forging press 60 includes a first die 14 and a second die 12 matable with each other to form a forging die. The first die 14 is usually fixed, and then the second die 12 can move following the movable beam 5 of the forging press 60 , so as to forge the forging blank 13 between the first die 14 and the second die 12 .

[0028] In addition, the forging press 60 also includes a hydraulic system 50 . The hydraulic system 50 includes a first oil pump 7 , a reversing valve 2 , a proportional valve 3 and a crossbeam drive cylinder 4 which are sequentially connected to the oil tank 1 . During the working process, the first oil pump 7 first delivers the hydraulic oil in the oil tank 1 to the reversing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com