Vehicle wheel low-pressure casting system

A low-pressure casting and wheel technology, which is applied in the field of aluminum alloy wheel casting, can solve problems such as difficult to achieve unified standards for product quality control, difficult to achieve unified standards for time control, and complex structure of processing site equipment, so as to facilitate accurate control of travel and improve products. The effect of quality and firm support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

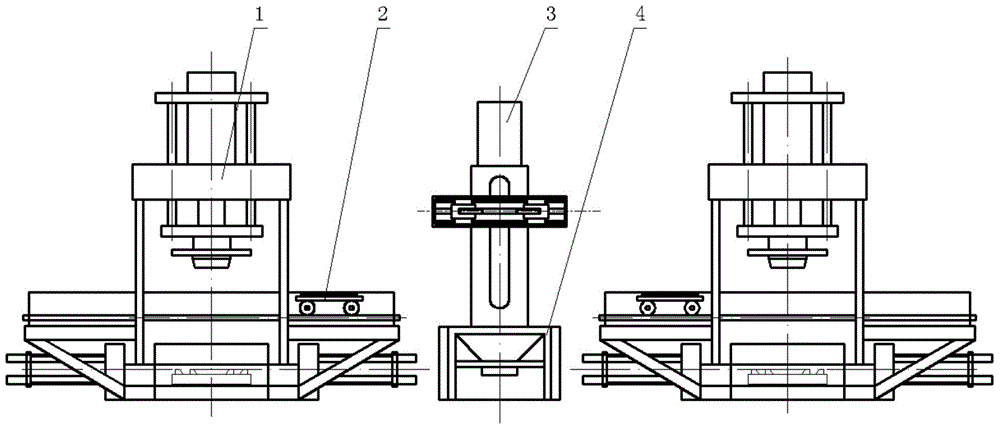

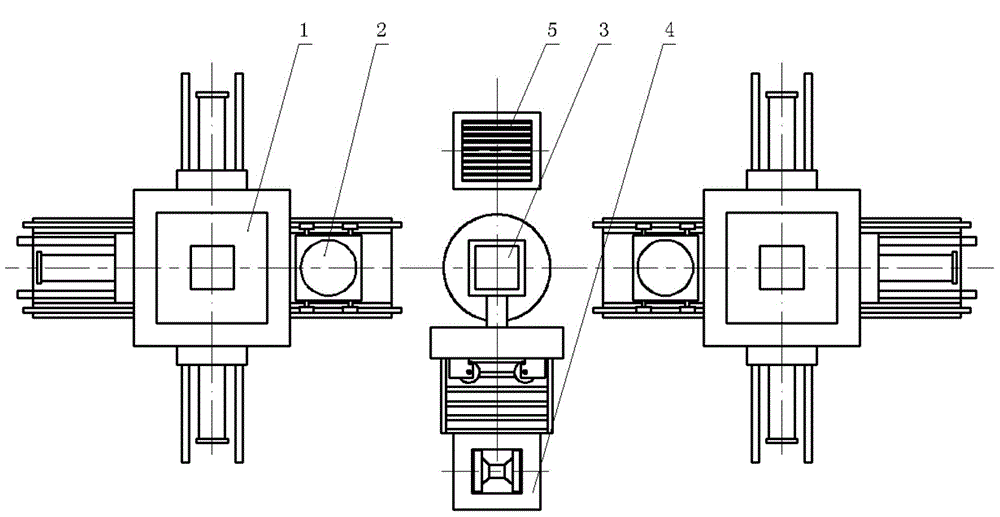

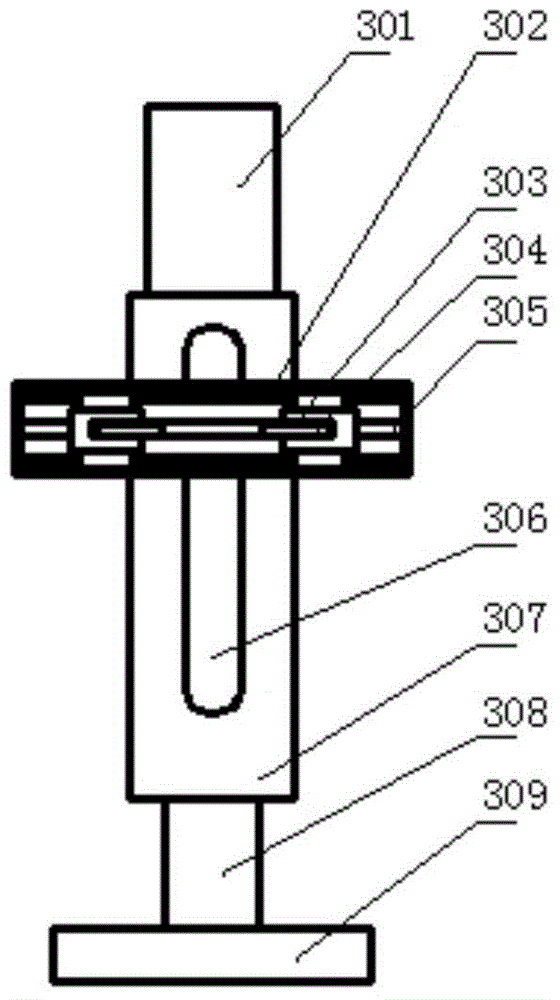

[0033] A wheel low-pressure casting system, including a casting machine 1, a transfer trolley 2, a rotary manipulator 3, a constant temperature pool 5 and a detection platform 4, with figure 2 The direction is explained. There is a casting machine symmetrically spaced on both lateral sides of the rotary manipulator. A transmission trolley is guided and slid between the casting machine and the rotary manipulator. The transmission trolley is controlled by the industrial computer between the casting machine and the rotary manipulator. The horizontal reciprocating movement on the guide rail between; the longitudinal side of the rotary manipulator is provided with a constant temperature water pool at inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com