Bottle cap assembly separating materials and water

A technology for bottle caps and feed water, applied in the field of container caps, to achieve the effects of extending shelf life, improving freshness, and high convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

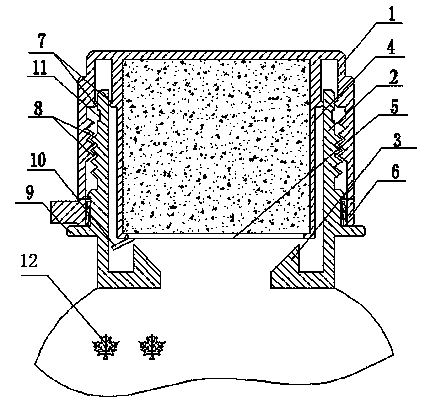

[0017] Such as figure 1 It is a structural diagram of an embodiment of the present invention. Since the focus of the present invention lies in the structure of the bottle mouth 2 and the bottle cap 1, there is no need to describe the bottle body. The bottle mouth 2 can be fixed with the bottle body in various ways. The prior art Some of them are directly formed, and some are fixed by hot-melt connection.

[0018] The inner side of bottle cap 1 and the outer wall of bottle cap 2 are provided with threads 8 with consistent specifications, and bottle cap 1 and bottleneck 2 are connected by threads. It can be unscrewed and separated when in use, and it is tightened when it leaves the factory.

[0019] The bottle cap 1 is provided with a bucket 4, which is used to place beverage brewing materials, such as: powder, granules, blocks processed from food, tonics, fruits and vegetables, and Chinese medicinal materials for brewing beverages. material, bag material and concentrated juic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com