Mulberry enzyme and production process thereof

A production process, mulberry technology, applied in the field of mulberry enzyme and production process, can solve the problems of complex preparation process, unfavorable absorption, single function, etc., and achieve the effect of simple raw material composition, good for human body absorption, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

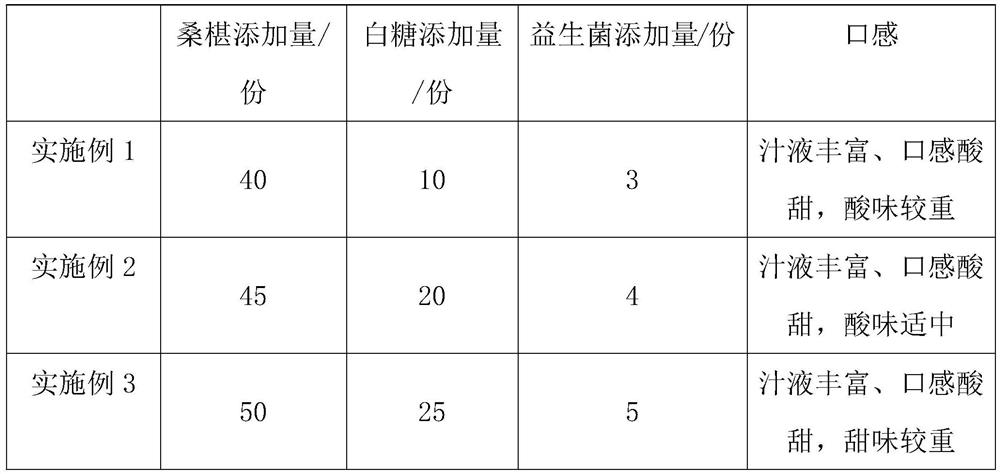

[0021] A kind of mulberry enzyme, the formula comprises: mulberry, white sugar and probiotics, the parts by weight of each component are: 40 parts of mulberry, 10 parts of white sugar and 3 parts of probiotics.

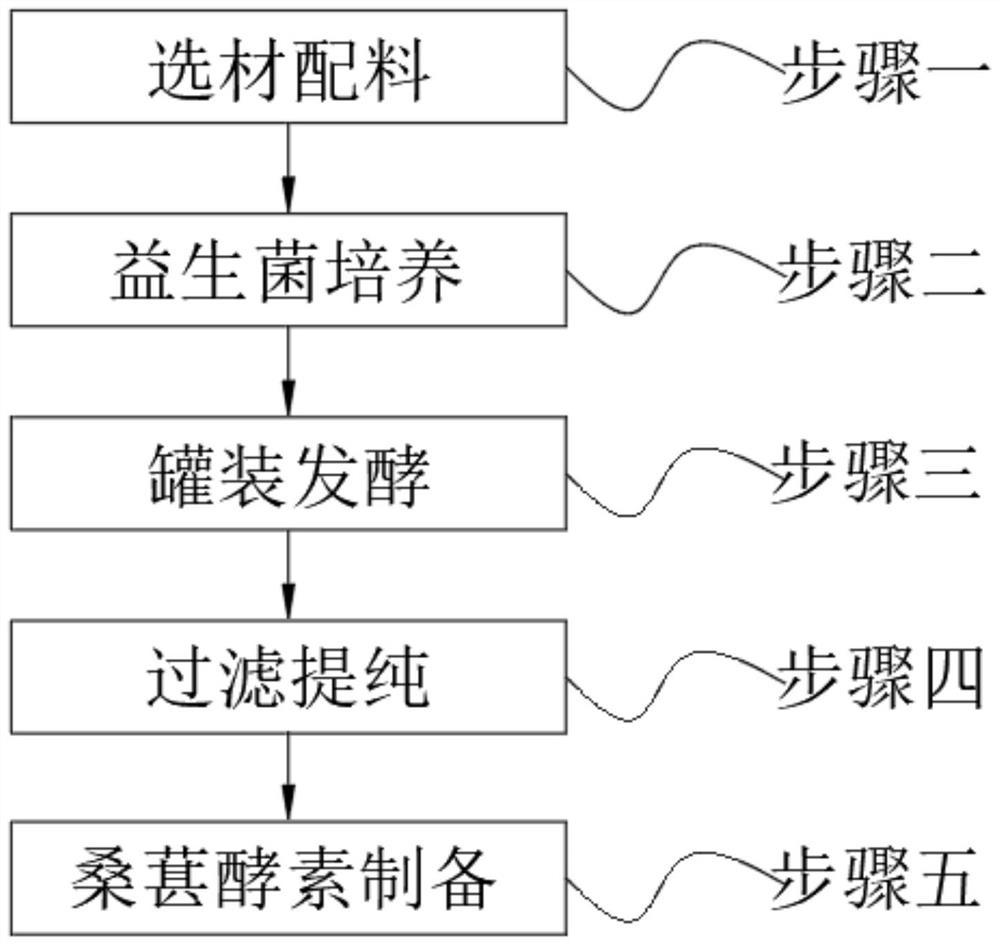

[0022] A production process of mulberry enzyme, comprising step 1, material selection and ingredients; step 2, probiotic culture; step 3, canned fermentation; step 4, filtration and purification; step 5, preparation of mulberry enzyme;

[0023] Wherein in the above-mentioned step 1, at first select ripe and plump, dark red mulberry fruit as raw material, rinse with clear water, then drain, destem, and crush for later use;

[0024] Wherein in the above-mentioned step 2, the bacterial strain of probiotic is activated, and the bacterium liquid of probiotic is obtained after cultivating for 48 hours, and the probiotic is Lactobacillus and Acetobacter;

[0025] Wherein in the above-mentioned step three, after mixing the spare raw materials and white sugar obtained in the s...

Embodiment 2

[0029] A kind of mulberry enzyme, the formula comprises: mulberry, white sugar and probiotics, the parts by weight of each component are: 45 parts of mulberry, 20 parts of white sugar and 4 parts of probiotics.

[0030] A production process of mulberry enzyme, comprising step 1, material selection and ingredients; step 2, probiotic culture; step 3, canned fermentation; step 4, filtration and purification; step 5, preparation of mulberry enzyme;

[0031] Wherein in the above-mentioned step 1, at first select ripe and plump, dark red mulberry fruit as raw material, rinse with clear water, then drain, destem, and crush for later use;

[0032] Wherein in the above-mentioned step 2, the bacterial strain of probiotic is activated, and the bacterium liquid of probiotic is obtained after cultivating for 48 hours, and the probiotic is Lactobacillus and Acetobacter;

[0033] Wherein in the above-mentioned step three, after mixing the spare raw materials and white sugar obtained in the s...

Embodiment 3

[0037] A kind of mulberry enzyme, the formula comprises: mulberry, white sugar and probiotics, the parts by weight of each component are respectively: 50 parts of mulberry, 25 parts of white sugar and 5 parts of probiotics.

[0038] A production process of mulberry enzyme, comprising step 1, material selection and ingredients; step 2, probiotic culture; step 3, canned fermentation; step 4, filtration and purification; step 5, preparation of mulberry enzyme;

[0039] Wherein in the above-mentioned step 1, at first select ripe and plump, dark red mulberry fruit as raw material, rinse with clear water, then drain, destem, and crush for later use;

[0040] Wherein in the above-mentioned step 2, the bacterial strain of probiotic is activated, and the bacterium liquid of probiotic is obtained after cultivating for 48 hours, and the probiotic is Lactobacillus and Acetobacter;

[0041] Wherein in the above-mentioned step three, after mixing the spare raw materials and white sugar obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com