Aerated brick using automobile waste and preparation method thereof

A technology for aerated bricks and waste materials, applied in the field of aerated bricks, can solve the problems of troublesome preparation, poor compressive strength of aerated bricks, complicated formulations, etc., and achieve the effects of easy acquisition, good compressive strength, and simple raw material components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

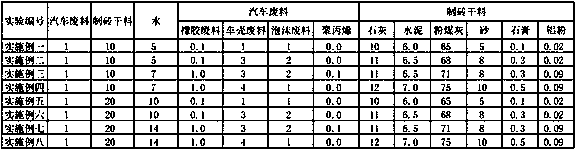

Examples

Embodiment 1

[0056] An aerated brick using automobile waste, its raw materials include automobile waste, brick-making dry material and water, and the weight ratio of automobile waste, brick-making dry material and water is set at 1:10:5.

[0057] Automobile waste consists of the following parts by weight:

[0058] 0.1 part of rubber waste, mainly composed of waste automobile tire rubber;

[0059] 1 piece of roof trim waste, mainly containing polyurethane plastic, polyolefin binder and glass fiber;

[0060] 1 part of foam waste, mainly composed of polyurethane foam.

[0061] Brick making dry material is made up of following parts by weight:

[0062] 10 parts of lime;

[0063] 6 parts of cement;

[0064] 65 parts of fly ash;

[0065] 5 parts of sand;

[0066] 0.1 parts of gypsum;

[0067] 0.02 parts of aluminum powder.

[0068] The above-mentioned preparation method of an aerated brick using automobile waste comprises the following steps:

[0069] S1. Grinding the rubber waste into ...

Embodiment 2

[0079] An aerated brick using automobile waste, its raw materials include automobile waste, brick-making dry material and water, and the weight ratio of automobile waste, brick-making dry material and water is set at 1:10:5.

[0080] Automobile waste consists of the following parts by weight:

[0081] 0.1 part of rubber waste, mainly composed of waste automobile tire rubber;

[0082] 3 parts of roof trim waste, mainly containing polyurethane plastic, polyolefin binder and glass fiber;

[0083] 2 parts of foam waste, mainly composed of polyurethane foam.

[0084] Brick making dry material is made up of following parts by weight:

[0085] 11 parts of lime;

[0086] 6.5 parts of cement;

[0087] 68 parts of fly ash;

[0088] 8 parts of sand;

[0089] 0.3 parts of gypsum;

[0090] 0.02 parts of aluminum powder.

[0091] The preparation method of the aerated brick in this embodiment is the same as the preparation method of the first embodiment described above.

Embodiment 3

[0093] An aerated brick using automobile waste, its raw materials include automobile waste, brick-making dry material and water, and the weight ratio of automobile waste, brick-making dry material and water is set at 1:10:7.

[0094] Automobile waste consists of the following parts by weight:

[0095] 1.0 parts of rubber waste, mainly composed of waste automobile tire rubber;

[0096] 3 parts of roof trim waste, mainly containing polyurethane plastic, polyolefin binder and glass fiber;

[0097] 2 parts of foam waste, mainly composed of polyurethane foam;

[0098] 0.1 part of polyolefin adhesive, the adhesive is polypropylene.

[0099] Brick making dry material is made up of following parts by weight:

[0100] 11 parts of lime;

[0101] 6.5 parts of cement;

[0102] 71 parts of fly ash;

[0103] 8 parts of sand;

[0104] 0.3 parts of gypsum;

[0105] 0.09 parts of aluminum powder.

[0106] The above-mentioned preparation method of an aerated brick using automobile wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com