Method for catalyzing liquid-phase nitration of fat paraffin by using carbon-based solid acid catalyst

A solid acid catalyst, carbon-based solid acid technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of easy decomposition of catalysts, complex experimental operations, Low catalytic activity and other problems, to achieve the effect of separation, cheap and easy to obtain raw materials, low catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

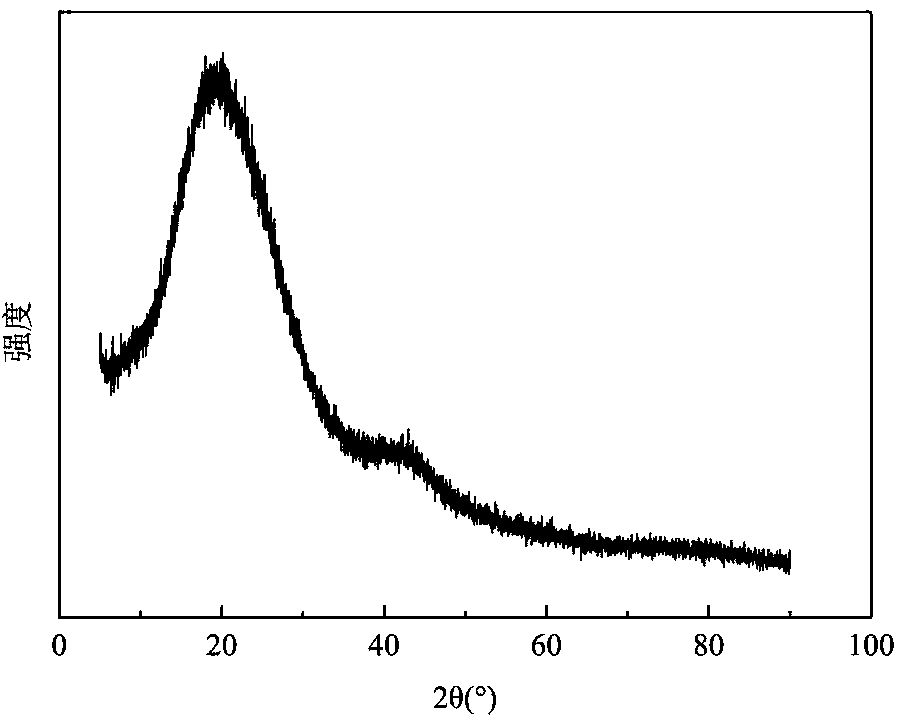

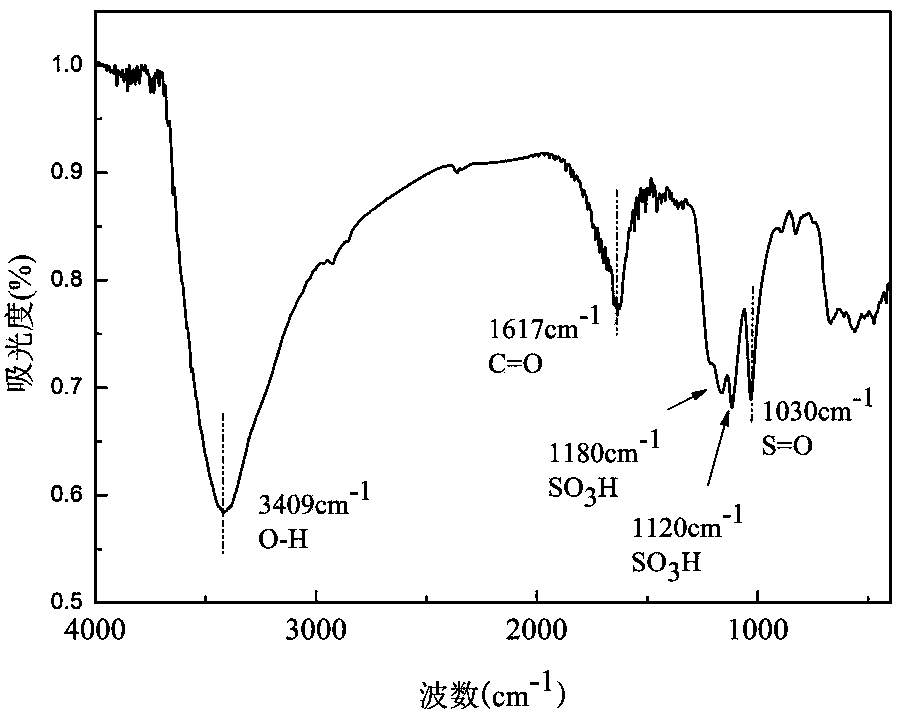

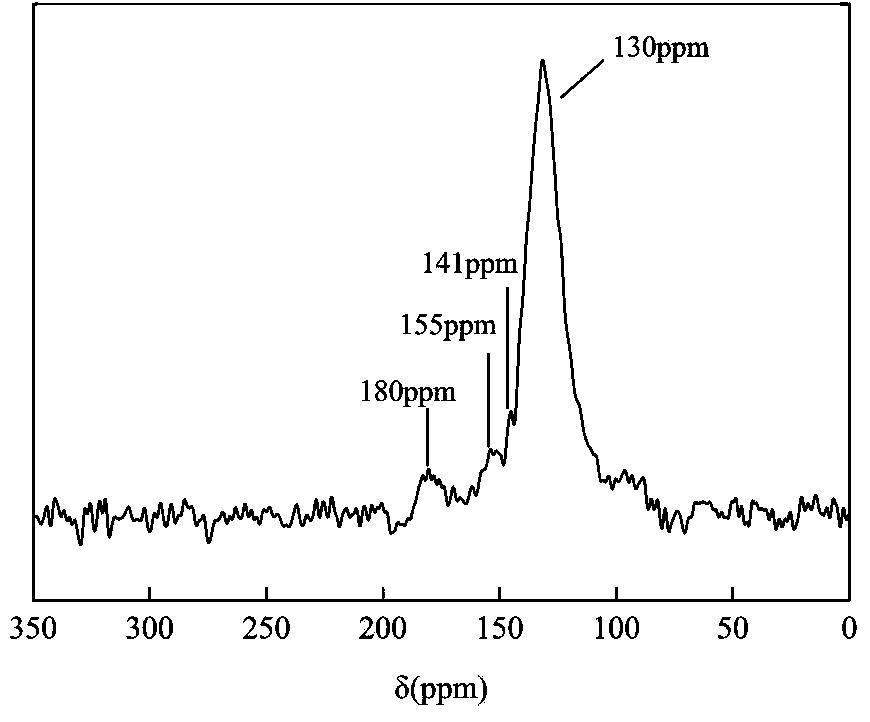

[0030] Synthetic steps of naphthalenesulfonic acid methylal carbon-based solid acid catalyst:

[0031] The first step, takes by weighing 10g naphthalene and puts into there-necked flask, under N 2 Under protection, heat it in an oil bath at 150°C to melt it;

[0032] In the second step, add 12mL of sulfuric acid with a mass concentration of 98% to the naphthalene melted in the first step, then raise the temperature to 160°C and keep the temperature constant for four hours to obtain a black liquid;

[0033] In the third step, cool the black liquid in the second step to 105°C, add 14 mL of formaldehyde solution with a mass concentration of 37-40%, raise the temperature to 110°C, and react for 12 hours to obtain a black crude product;

[0034] In the fourth step, use hot water higher than 85°C to filter and wash the black crude product obtained in the third step until there is no SO in the filtrate 4 2- Till now, the resulting filter cake was vacuum-dried at 120°C for 24 hours...

Embodiment 2

[0048] The steps are the same as in Example 2, except that in the third step, 10 mL of formaldehyde solution with a mass concentration of 37 to 40% is added, and the catalyst A is prepared in the fourth step 1 . Its specific surface area is 1.67m 2 / g, the average pore diameter is 14.2nm, and the pore volume is 0.00115cm 3 / g, acid density 4.16mmol / g.

Embodiment 3

[0050] The steps are the same as in Example 2, except that in the third step, 12 mL of formaldehyde solution with a mass concentration of 37 to 40% is added, and the catalyst A is prepared in the fourth step 2 . Its specific surface area is 1.75m 2 / g, the average pore diameter is 6.22nm, and the pore volume is 0.00075cm 3 / g, acid density 4.37mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com