Multi-vehicle automatic transmission fluid

A transmission, fluid technology, applied in the field of lubricating compositions, additive packages and lubricating transmissions, which can solve the problems of unfavorable Brookfield viscosity, no longer meeting low temperature viscosity limits, and unfavorable fluid properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

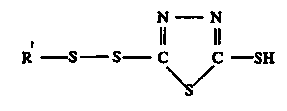

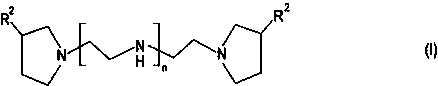

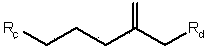

[0144] The following non-limiting examples are provided to further illustrate the features and advantages of one or more embodiments of the present invention. All fluids tested in the following table contained the components shown in Table 2 to provide a fully formulated lubricating fluid composition. In this table, the extreme pressure / antiwear agent (DMTD) is 2,5-bis-(hydrocarbyl disulfide)-1,3,4-thiadiazole and its monosubstituted equivalent 2-hydrocarbyl sulfide-5- A commercially available mixture of mercapto-1,3,4-thiadiazole, with approximately 85% dihydrocarbyl: 15% monohydrocarbyl, is called "thiadiazole" in the table. The friction modifier (FM1), the specific modifier of the embodiment of the present disclosure, is a mixture of the above-mentioned olefins (wherein at least 40% by weight of the olefin is C 10 -C 36 The friction modifier (FM2) is made of conventional linear α-olefins. The weight of all components in the table is the weight of the components in the final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com