Method for repairing large-diameter concrete water supply pipeline

A technology for water supply pipes and concrete, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., to facilitate transportation, ensure construction effects, and reduce hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

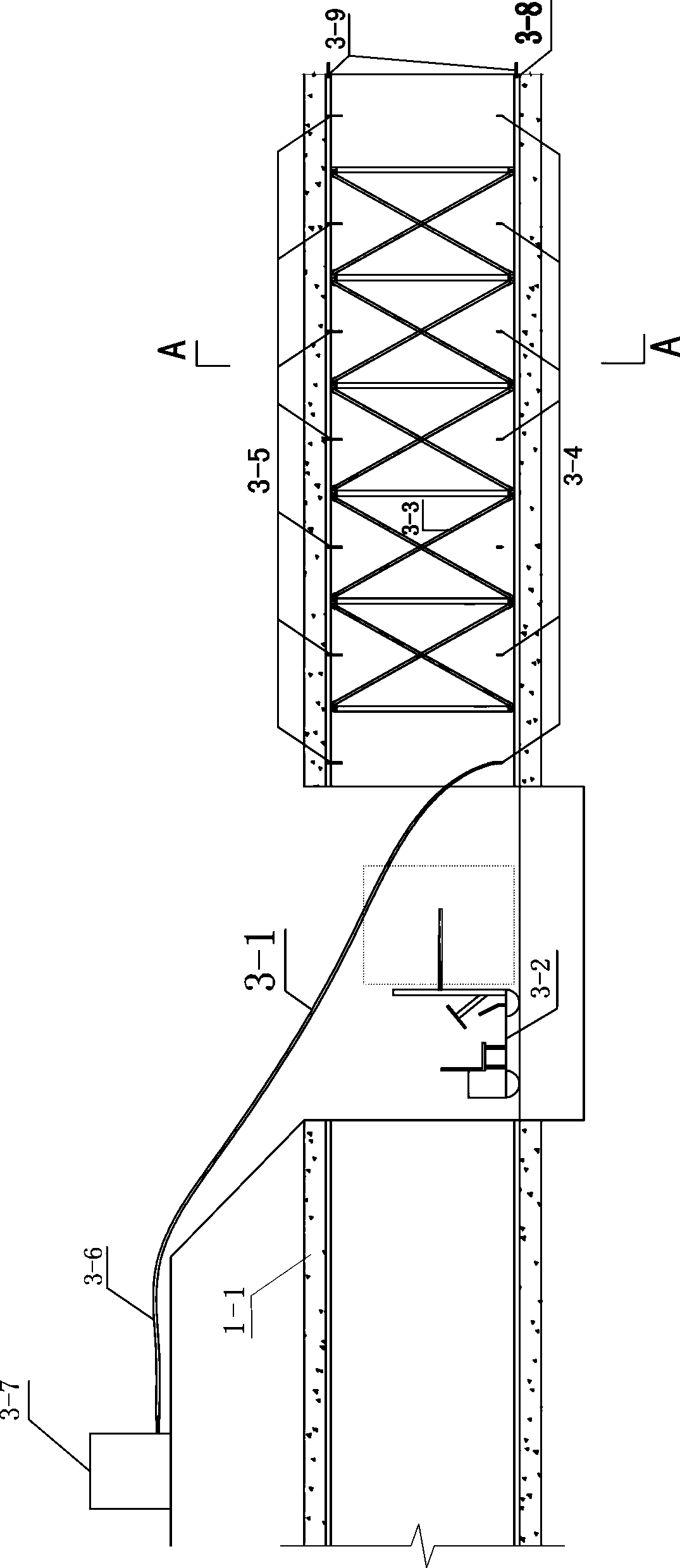

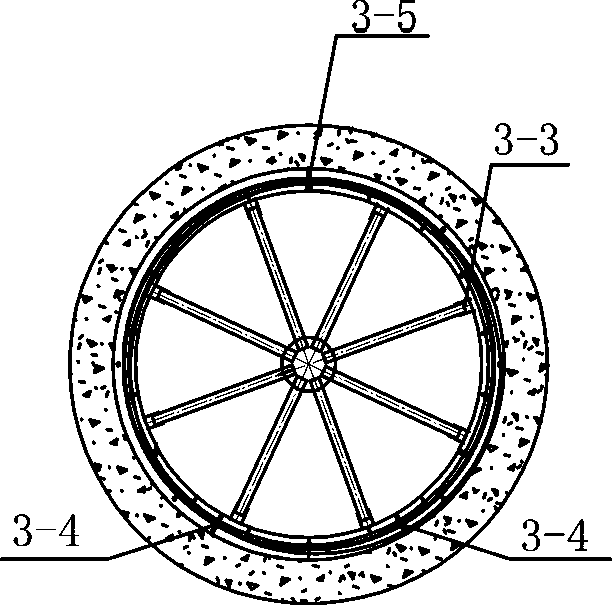

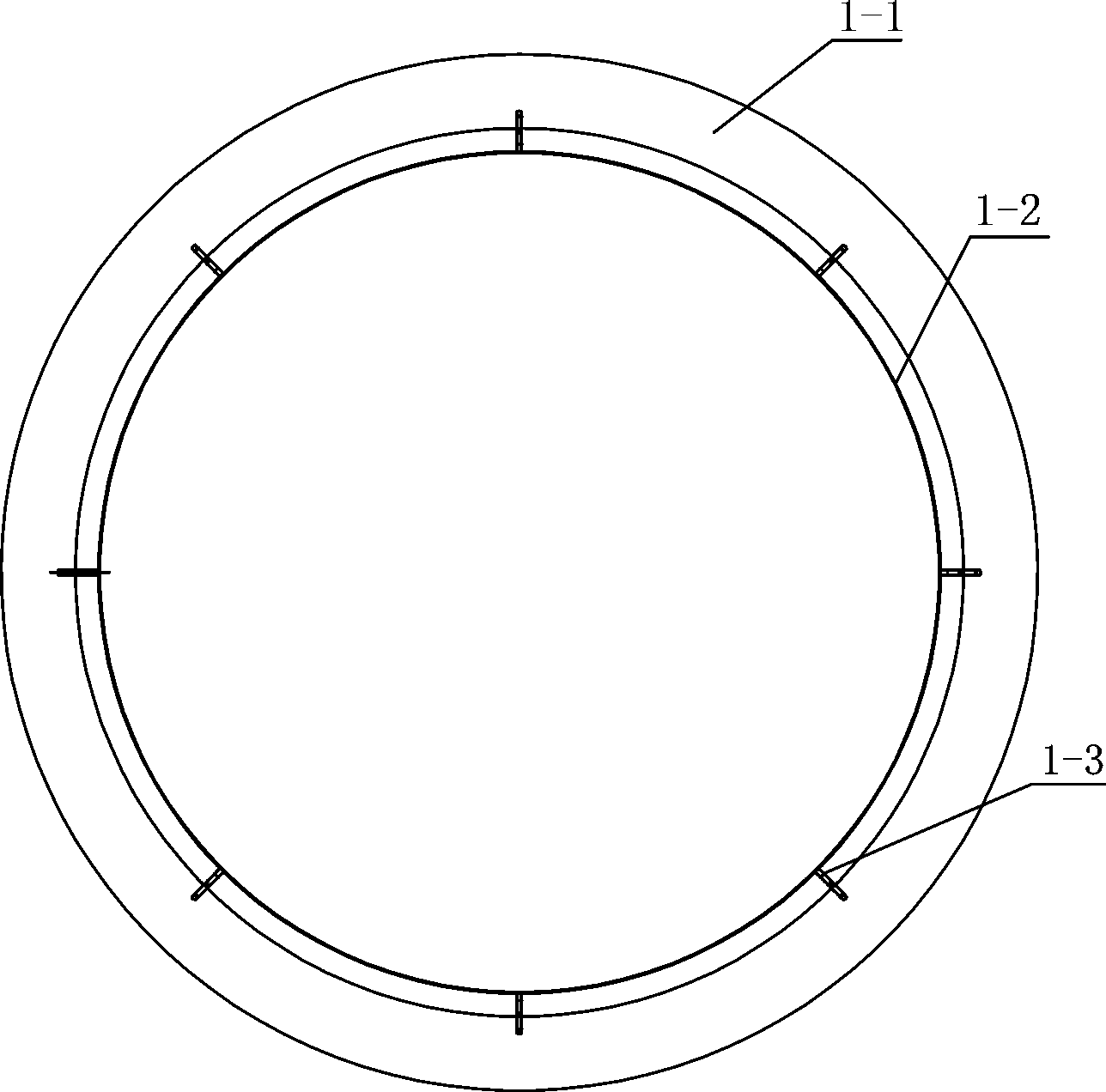

[0036] A method for repairing a large-diameter concrete water supply pipeline. Firstly, after the large-diameter concrete water supply pipeline 1-1 is shut off, enter the pipeline through an inspection hole, conduct a detailed inspection of the water leakage, determine the repair location, and formulate a repair plan;

[0037] Then select an appropriate location on the large-diameter concrete water supply pipeline 1-1 (taking into account transportation, grouting and other factors) and excavate the working pit 3-1 in sections. The specific size of the working pit 3-1 can meet the steel liner section 2 The hoisting and transportation of -1 shall prevail; and the inner wall of the large-diameter concrete water supply pipeline 1-1 to be repaired shall be chiseled, rinsed with wind and water, and pretreated at concentrated or obvious leaking parts (use plugging agent or The grouting method is used to seal the water leakage, and the aqueduct is buried to lead the water into the stee...

Embodiment 2

[0047]A method for repairing a large-diameter concrete water supply pipeline. Firstly, after the large-diameter concrete water supply pipeline 1-1 is shut off, enter the pipeline through an inspection hole, conduct a detailed inspection of the water leakage, determine the repair location, and formulate a repair plan;

[0048] Then select an appropriate location on the large-diameter concrete water supply pipeline 1-1 (taking into account transportation, grouting and other factors) and excavate the working pit 3-1 in sections. The specific size of the working pit 3-1 can meet the steel liner section 2 The hoisting and transportation of -1 shall prevail; and the inner wall of the large-diameter concrete water supply pipeline 1-1 to be repaired shall be chiseled, rinsed with wind and water, and pretreated at concentrated or obvious leaking parts (use plugging agent or The grouting method is used to seal the water leakage, and the aqueduct is buried in the larger water leakage part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com