Smoke pyrolysis kiln and furnace combined sludge incineration device

A sludge incineration and combined technology, applied in incinerators, combustion methods, combustion types, etc., to reduce energy consumption, avoid deflagration, and prevent deflagration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

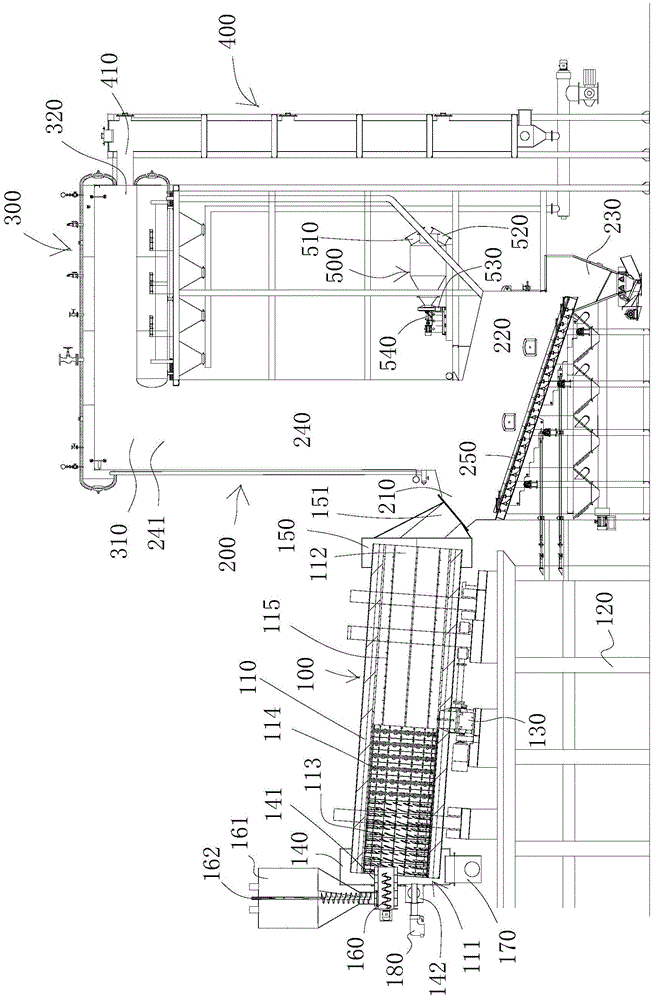

[0030] see figure 1 , the combined smoke pyrolysis kiln and furnace sludge incineration device shown in the figure includes a rotary pyrolysis device 100, an incinerator 200, a waste heat boiler 300, an air preheater 400 and a Taiyan wind matching device 500.

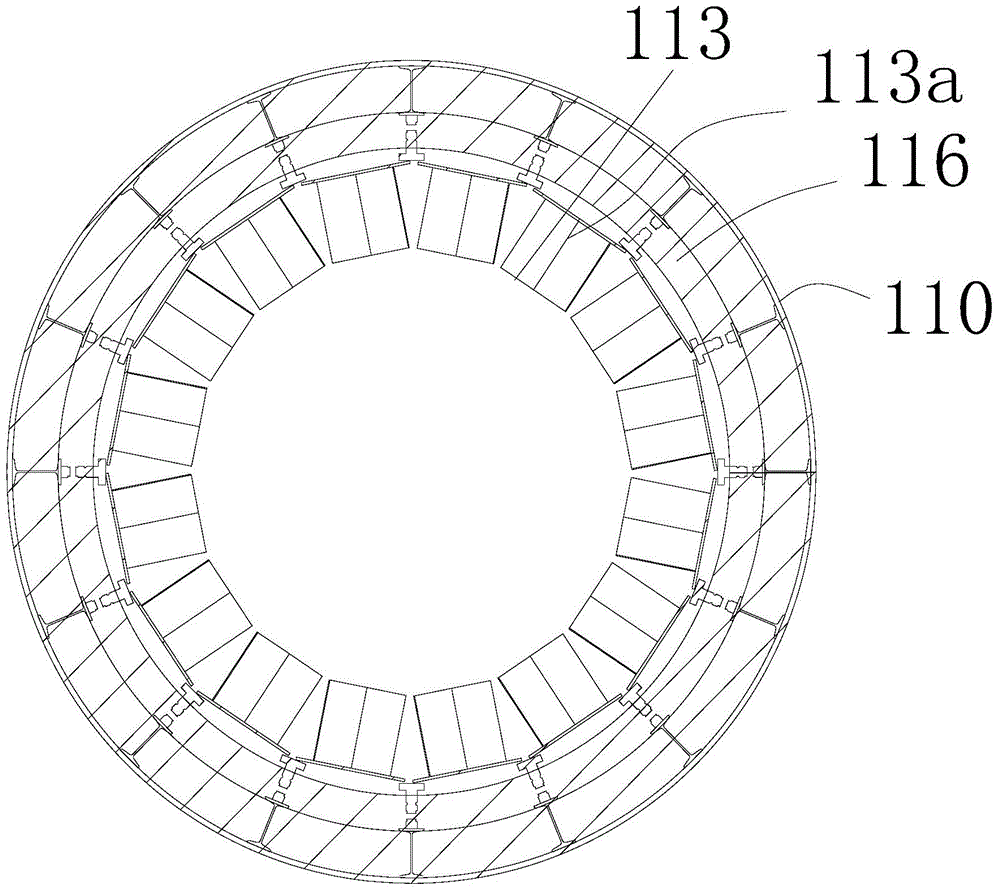

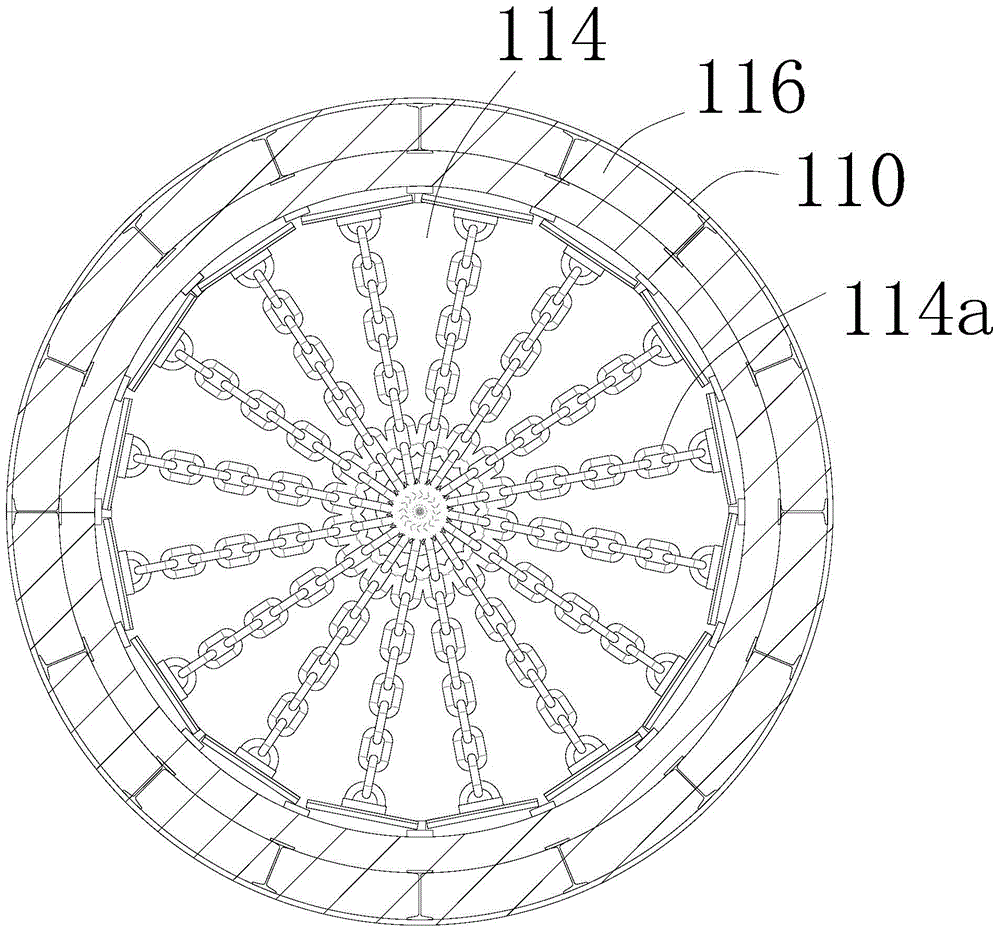

[0031] The rotary pyrolysis device 100 includes a rotary kiln body 110, a rotary kiln body support 120, and a rotary kiln body drive mechanism 130. The rotary kiln body drive mechanism 130 is installed on the rotary kiln body support 120 to support the rotary kiln body 110 and Drive the rotary kiln body 110 to rotate. The drive mechanism 130 of the rotary kiln body is driven by a frequency conversion speed control device to meet the needs of different sludge pyrolysis conditions.

[0032] The rotary kiln body 110 has two opposite ends, one of which is the feed end 111, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com