Application of graphene oxide in silver halide photographic material

A technology of photosensitive materials and graphene, which is applied in photosensitive materials, optics, instruments, etc., can solve problems such as poor optimization effects, and achieve the effect of significant sensitization, economic benefits, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

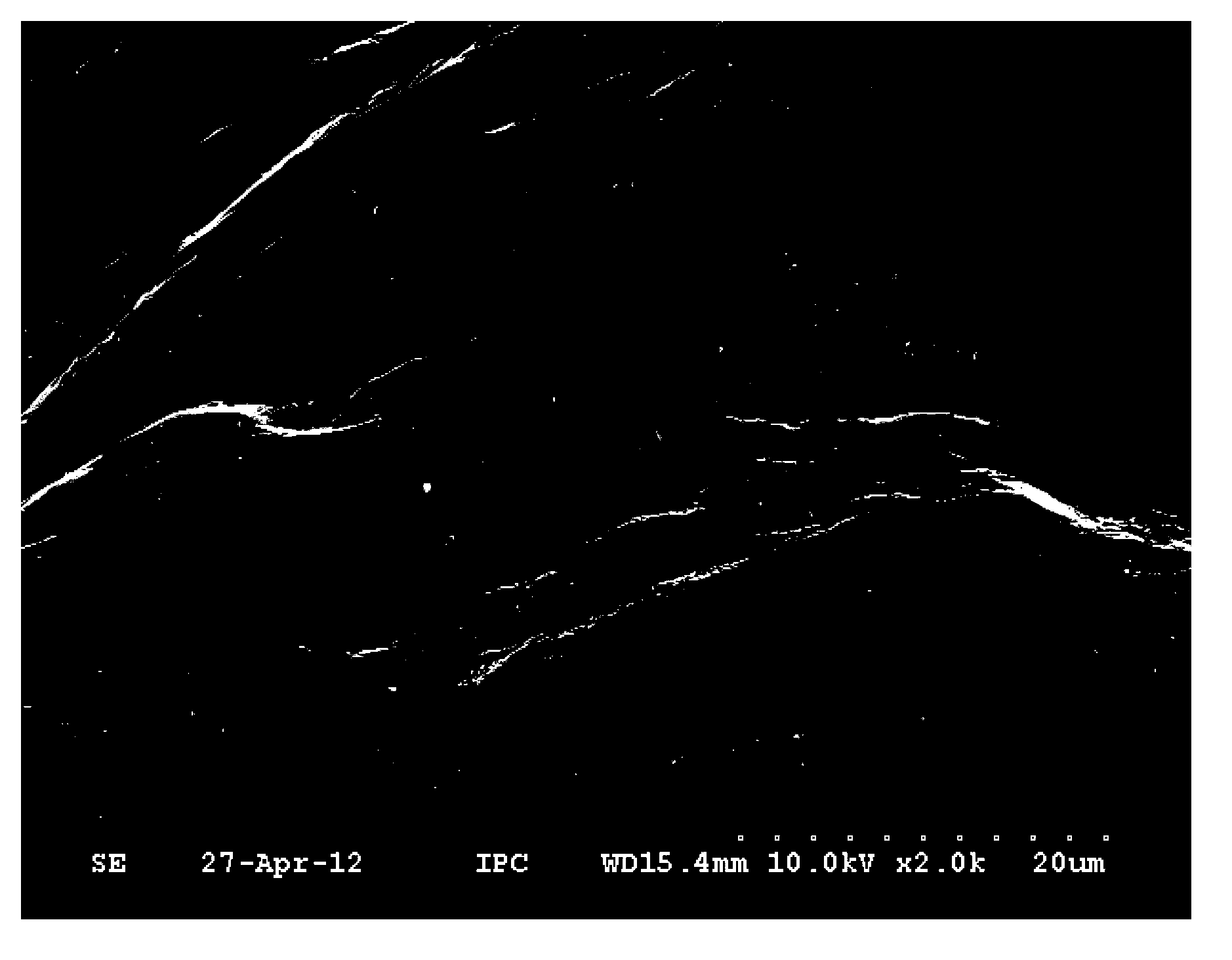

Image

Examples

Embodiment 1

[0017] After chemical sensitization and spectral sensitization, the silver bromoiodide photosensitive emulsion is coated on the film base by a photosensitive material coating machine at a temperature of 40°C, then condensed and dried to form a semi-finished product of the finished film. At 23°C and 60% humidity, it was left to balance for 7 days to obtain the finished film. Take out the finished film, cut it into an optical wedge with a size of 14cm×3.5cm, soak it in 0.01mg / mL graphene oxide aqueous dispersion for 5 minutes, then take it out and dry it in the air. , Expose under the condition of shutter time of 0.05 seconds, develop in PQ developer solution at 20°C for 5 minutes, wash with water, fix at F-5 for 10 minutes, take it out and dry it, use a color densitometer, and use the sensitivity Calculation formula S=1 / H (D0+01) See Table 1 for the indicators for measuring and calculating its photosensitive properties.

Embodiment 2

[0019] After chemical sensitization and spectral sensitization, the silver bromoiodide photosensitive emulsion is coated on the film base by a photosensitive material coating machine at a temperature of 40°C, then condensed and dried to form a semi-finished product of the finished film. At 23°C and 60% humidity, it was left to balance for 7 days to obtain the finished film. Take out the finished film, cut it into an optical wedge with a size of 14cm×3.5cm, soak it in 0.1mg / mL graphene oxide aqueous dispersion for 5 minutes, then take it out and dry it in the air. , Expose under the condition of shutter time of 0.05 seconds, develop in PQ developer solution at 20°C for 5 minutes, wash with water, fix at F-5 for 10 minutes, take it out and dry it, use a color densitometer, and use the sensitivity Calculation formula S=1 / H (D0+0.1) See Table 1 for the indicators for measuring and calculating its photosensitive properties.

Embodiment 3

[0021] After chemical sensitization and spectral sensitization, the silver bromoiodide photosensitive emulsion is coated on the film base by a photosensitive material coating machine at a temperature of 40°C, then condensed and dried to form a semi-finished product of the finished film. At 23°C and 60% humidity, it was left to balance for 7 days to obtain the finished film. Take out the finished film, cut it into an optical wedge with a size of 14cm×3.5cm, soak it in a 1mg / mL graphene oxide aqueous dispersion for 5 minutes, then take it out and dry it in the air. Expose with a shutter time of 0.05 seconds, develop in PQ developer solution at 20°C for 5 minutes, wash with water, fix at F-5 for 10 minutes, take it out and dry it, use a color densitometer, and use the sensitivity to calculate Formula S=1 / H (D0+0.1) See Table 1 for the indicators for measuring and calculating its photosensitive properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com